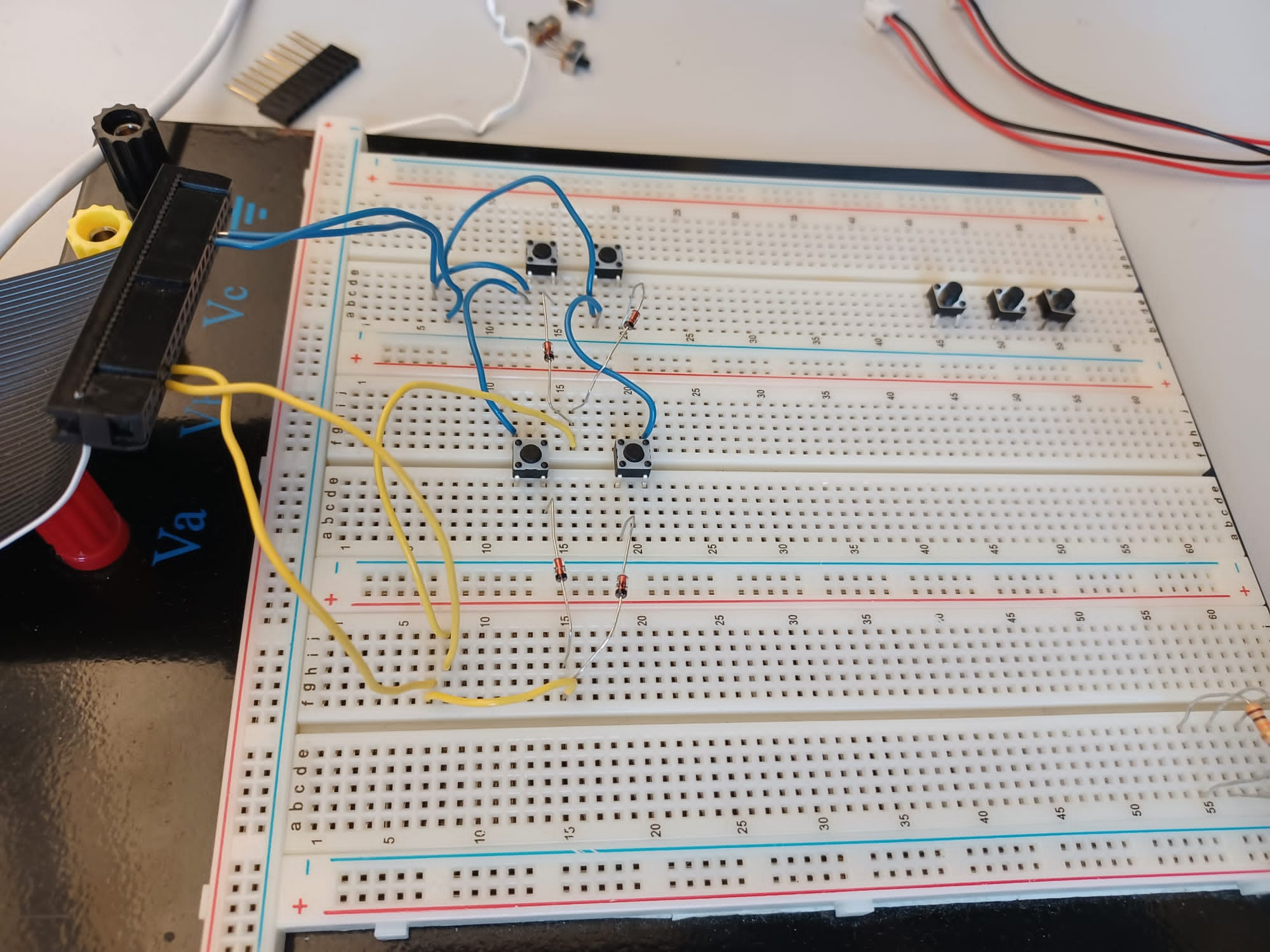

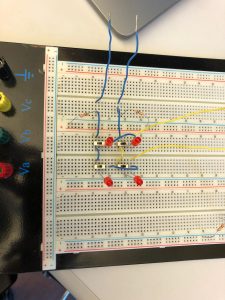

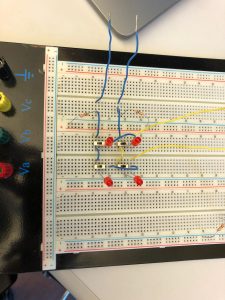

Before spring break, we tried making a better prototype. We did not fully understand how matrix scanning worked, so we assembled a new prototype. This did not work, and upon closer inspection we learned that our diodes were not the right type.

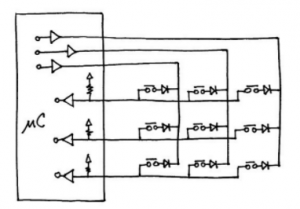

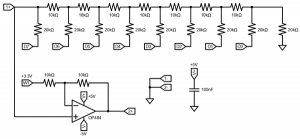

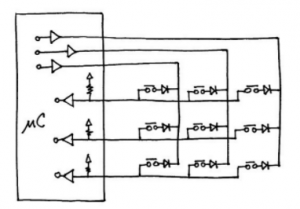

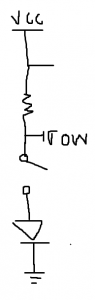

The scanning matrix works by quickly cycling through each column, such that the selected column is pulled to digital low and all other columns are at digital high. It then checks which rows have been pulled low from the switches.

Here is a smaller scale version of the switch.

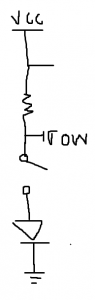

When we tried making the circuit, we failed because on closer inspection, we had the wrong kind of diode. We used LEDs, which on average drops 1.7 to 2 volts, which would mean that a row with a closed circuit would drop from 3.3 volts to 1.7 volts, which is still a digital high. We are now trying to find diodes with a lower voltage drop, around .3 volts, so that row can be pulled down to a voltage low. We have just ordered a new set of these diodes and are awaiting supplies.

We then moved on to testing the software without the diodes, which helped, but we had the expected ghosting issue. But since the ghosting only happened when multiple columns were on at a time, the circuit and software seems to work and should still work when we add the right diodes.

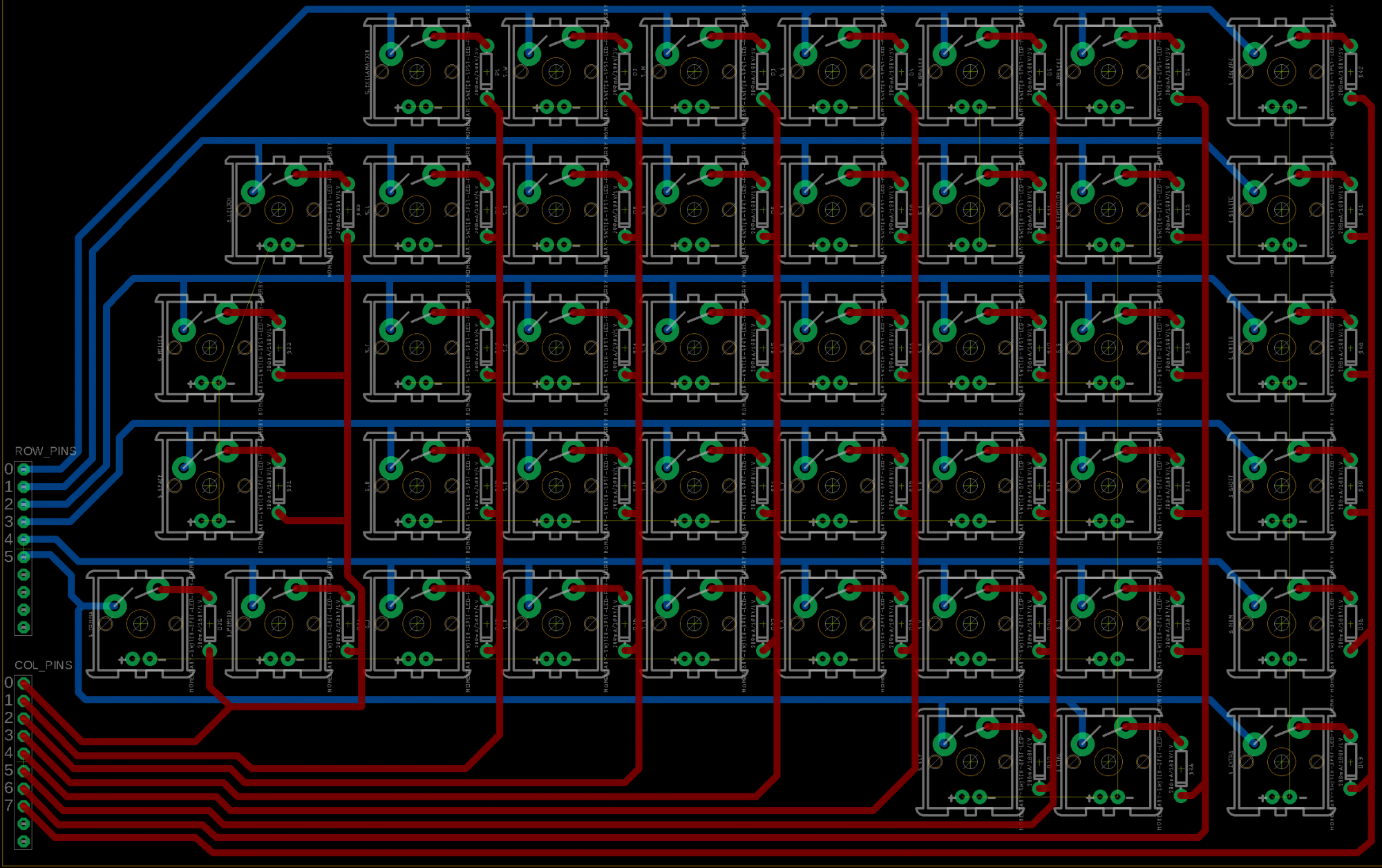

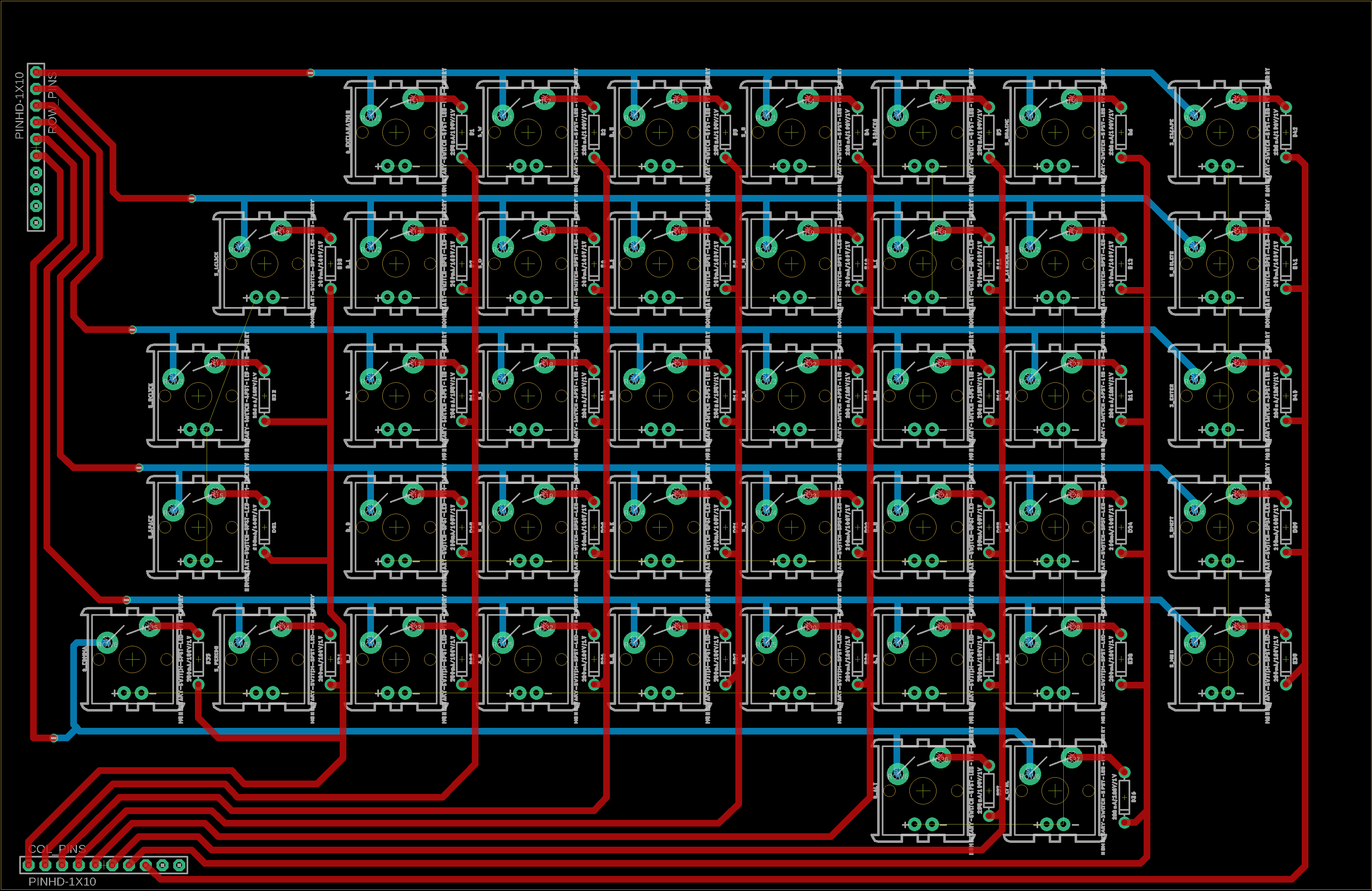

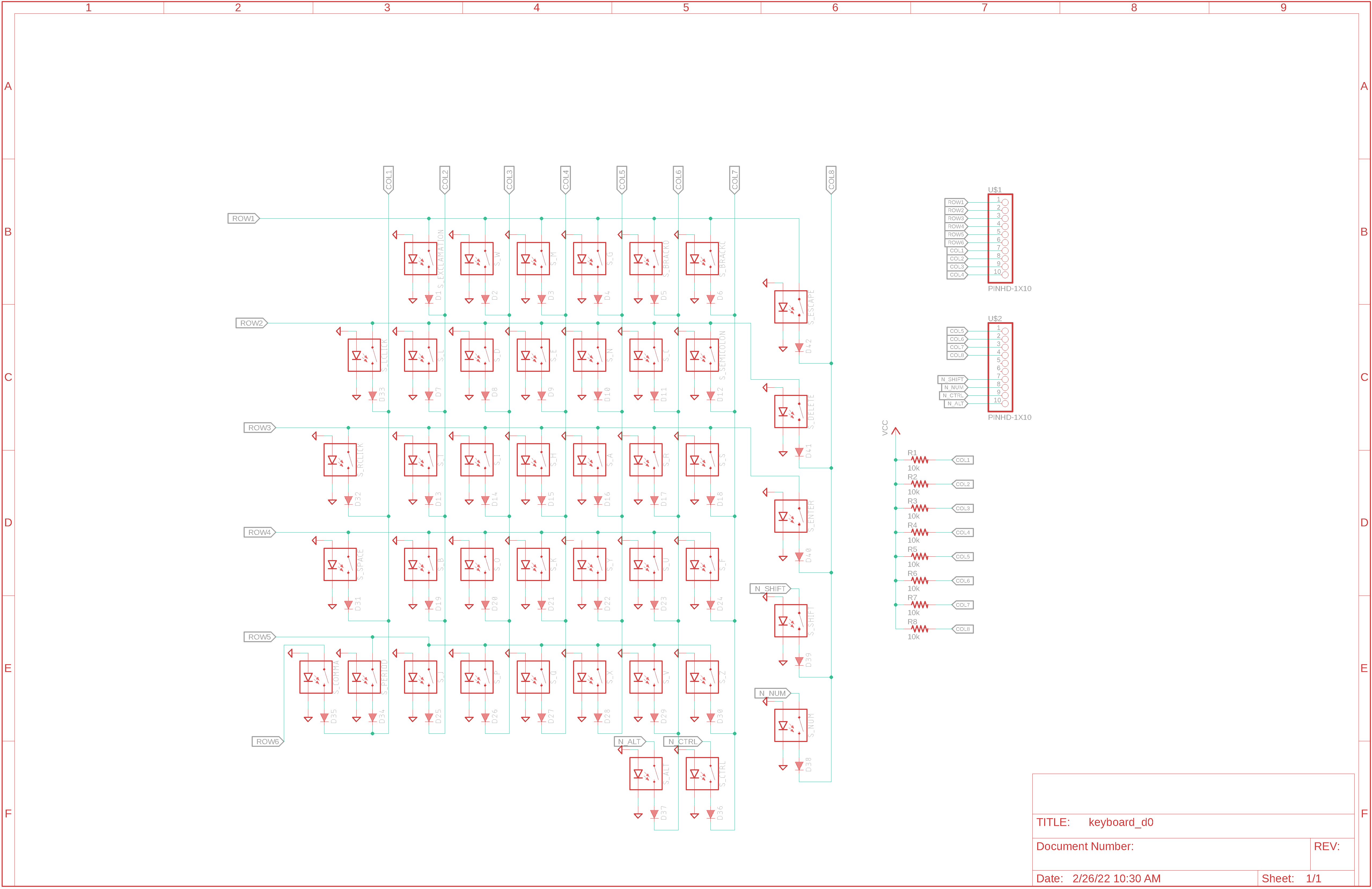

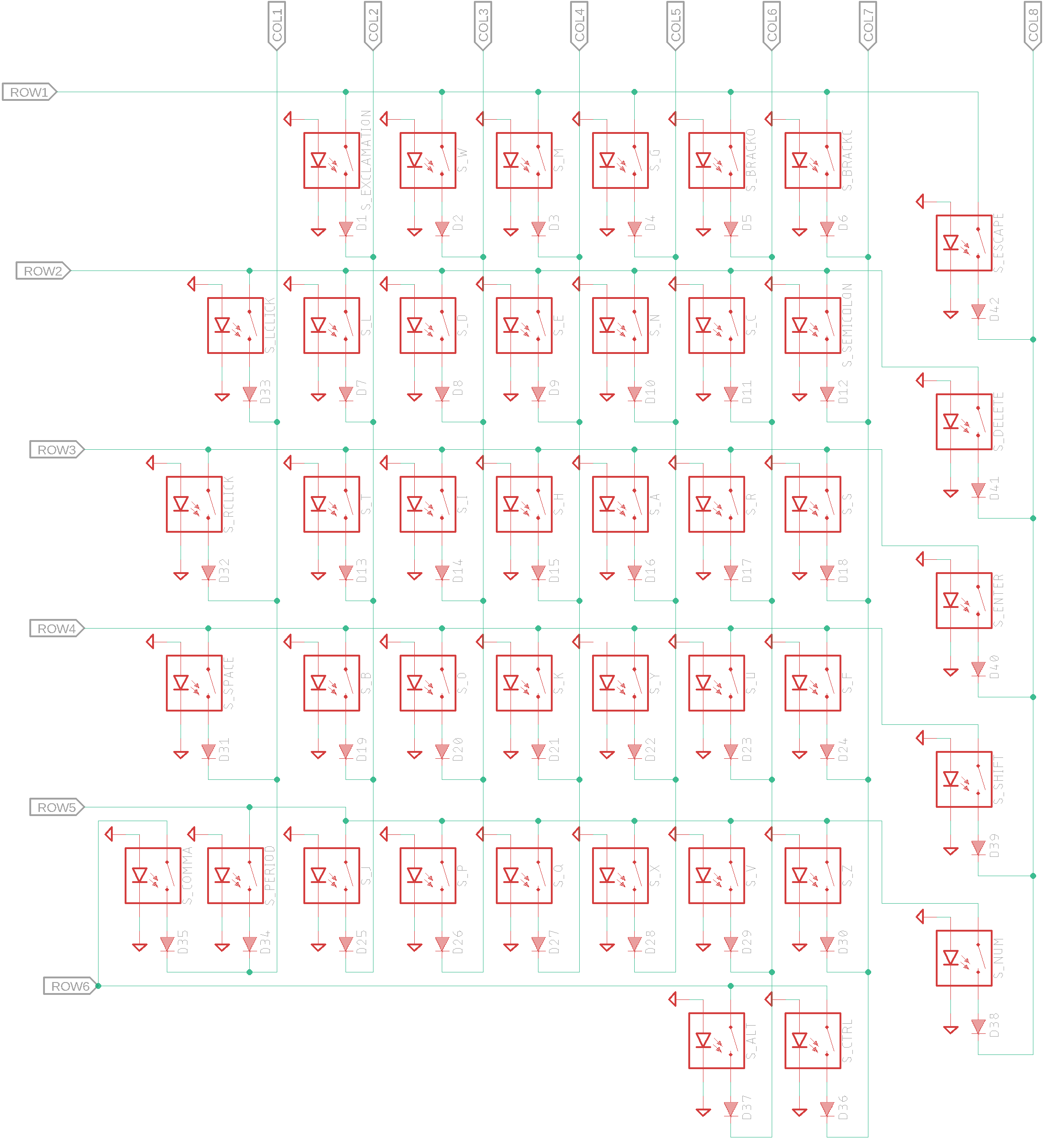

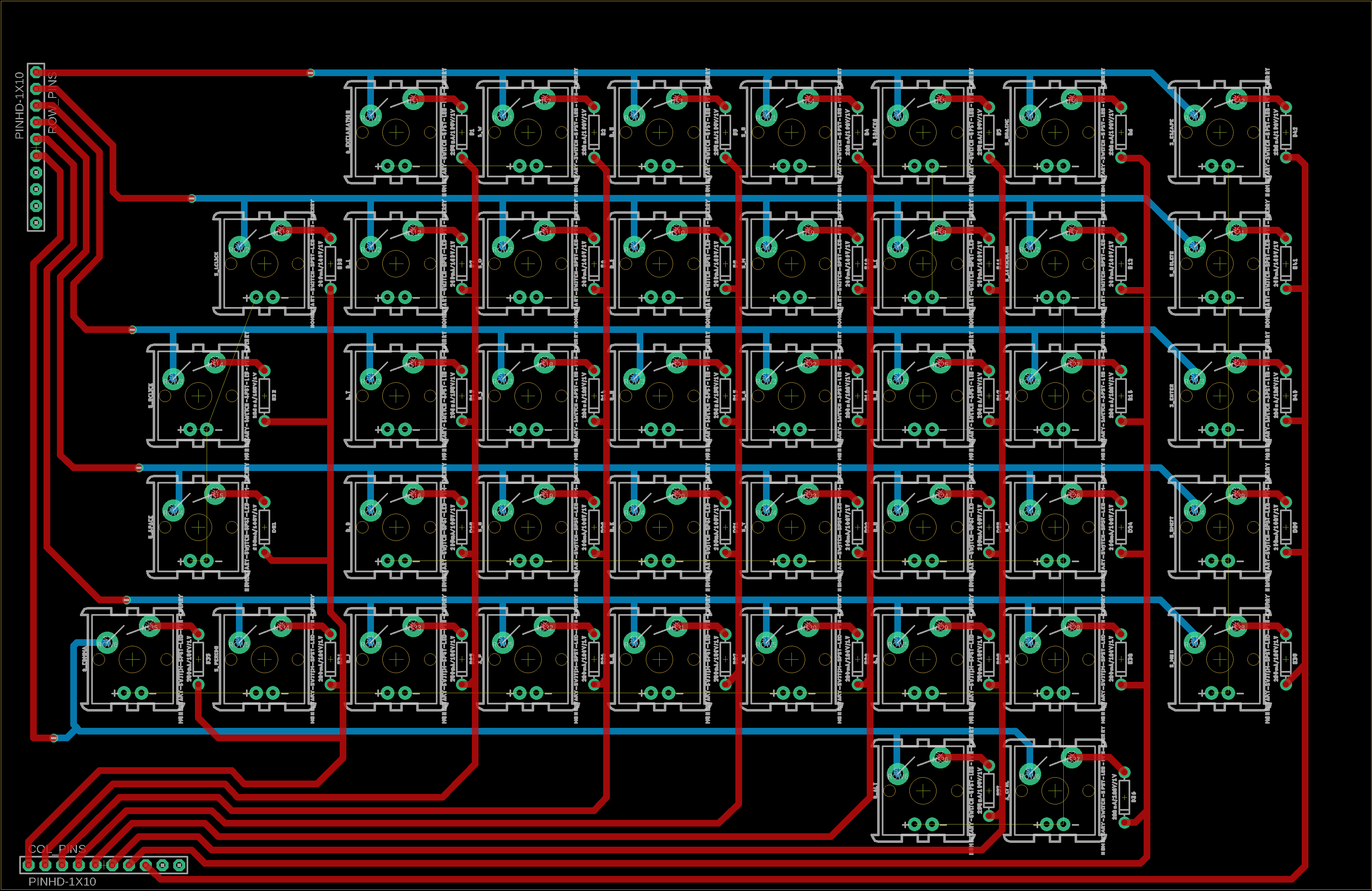

When it comes to making the PCB, we ran into issues because our board went over the maximum dimensions that Eagle free would allow, so we needed a proper Eagle education license. This was an annoying delay but I (Jorge) submitted my enrollment documentation and the license was supplied the next day. It was a minimal delay, and instead of getting the PCB design finished on Wednesday I got it done Friday. Next steps would be to revise it a little and then decide on a board manufacturer and order it some time next week.

Here below is the board PCB layout

[Note: More specifics on the design in Jorge’s personal status report]

Carlos is also going to reach out to CLASS this week. An organization which the professor in HCI recommended to put us in contact with someone with Spastic Hemiplegia.