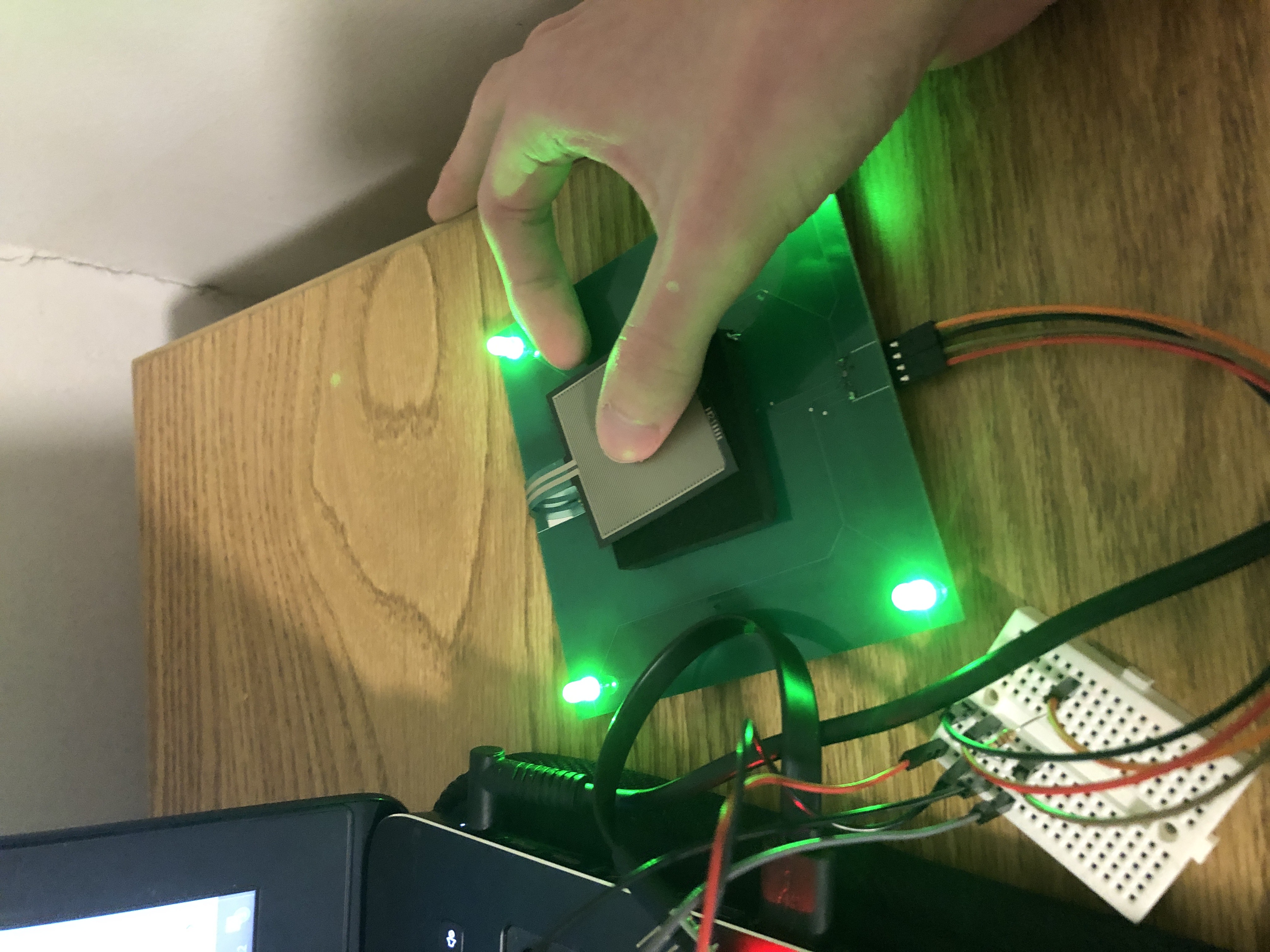

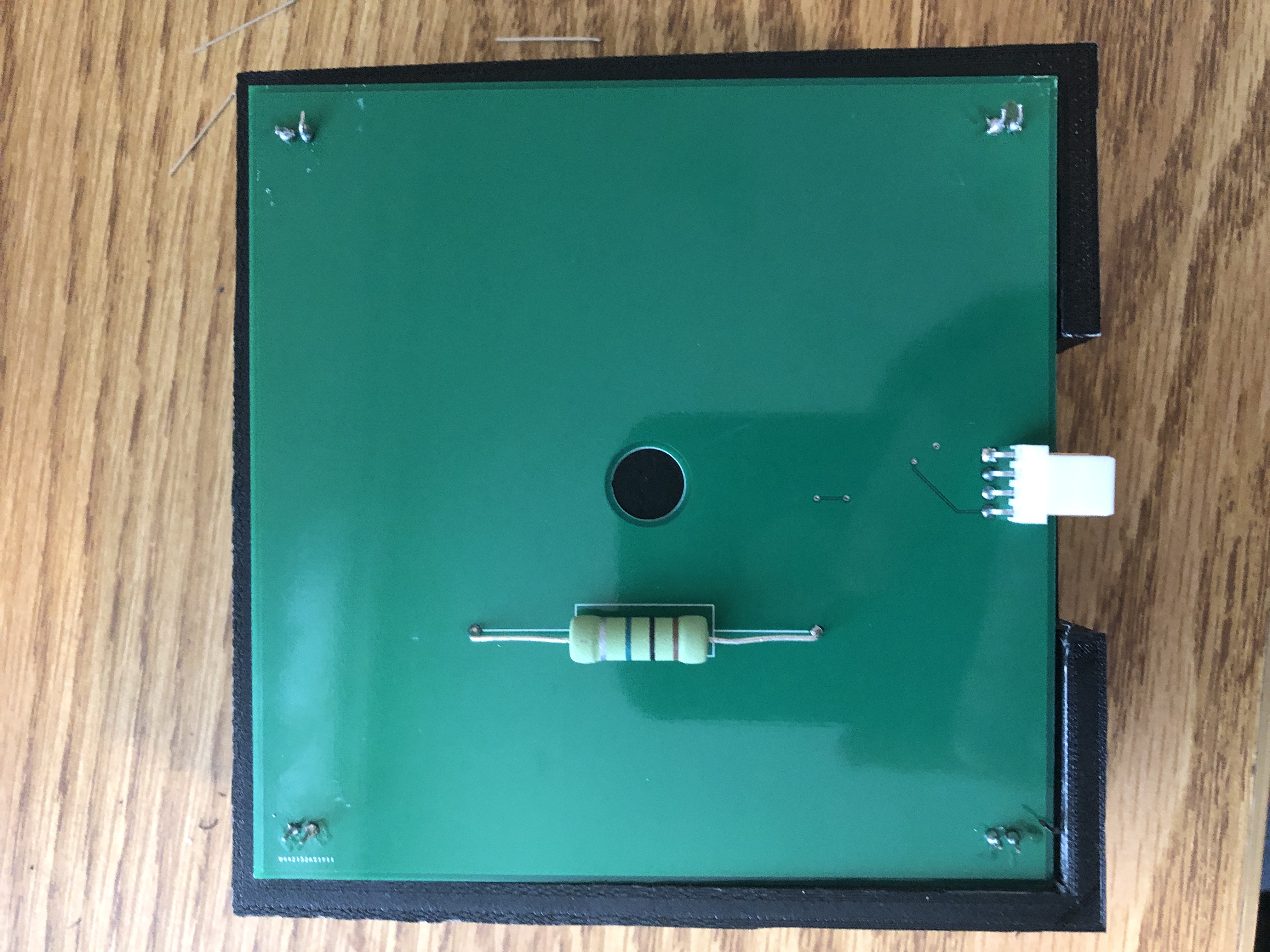

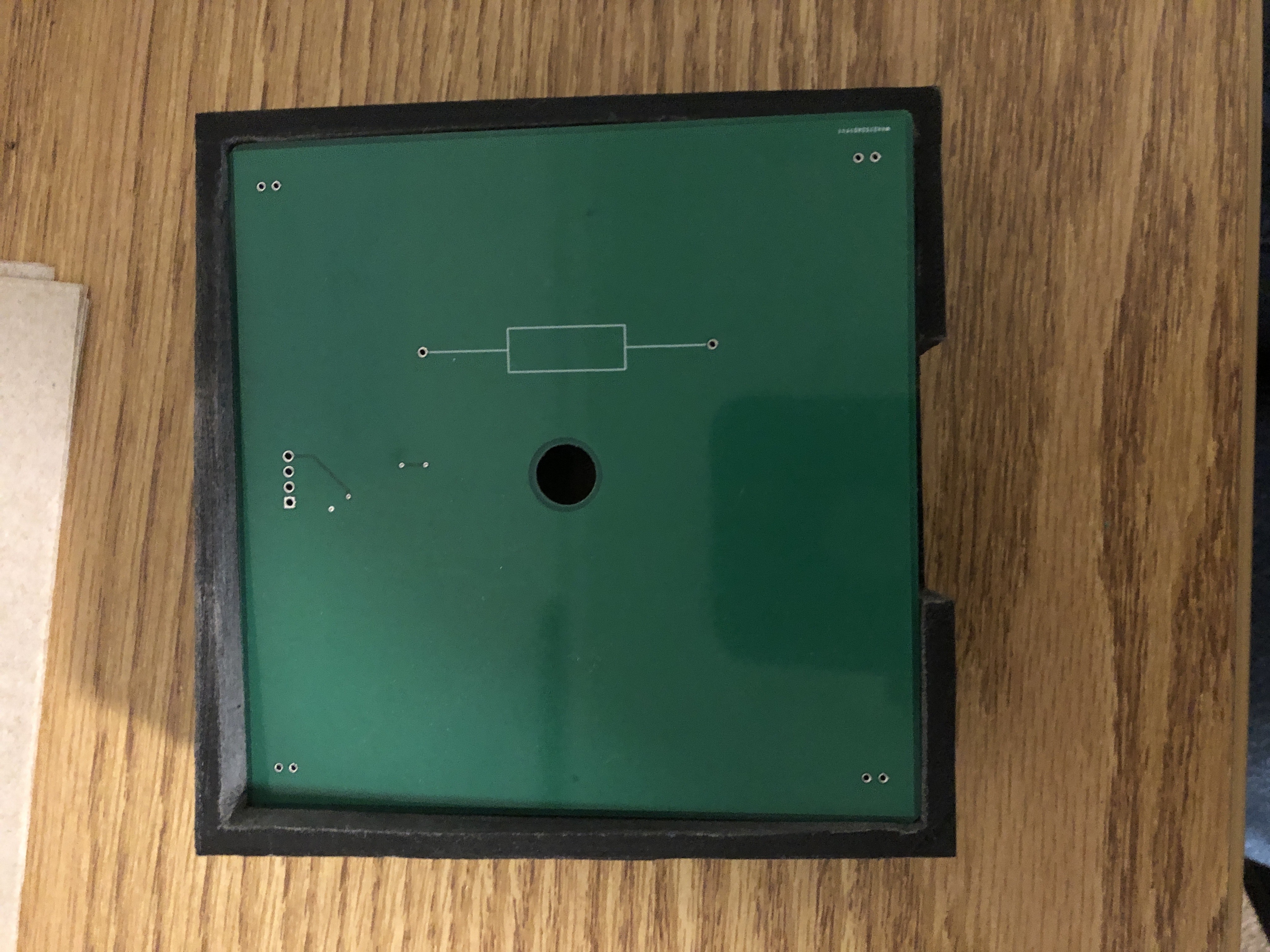

The majority of this week was spent preparing to print the final drum modules, as earlier this week the PCBs arrived from PCBway, and after soldering the components to verify that they perform as expected, I was ready to 3D print the final drum design. The only change I made from my recently posted drafts was to reduce the thickness of the top wall of the housing from 5 mm to 2 mm. This is mainly to allow the LEDs more room to stick through the holes in this layer, as I hadn’t originally accounted for how the stubs of the other through-holes components may prevent them from getting as close to the roof of the housing as the PCB would naturally allow.

The print had reduced scaffolding and height compared to the demo design, which brought the cost down from $56.50 previously to just $36.00 for this final version.

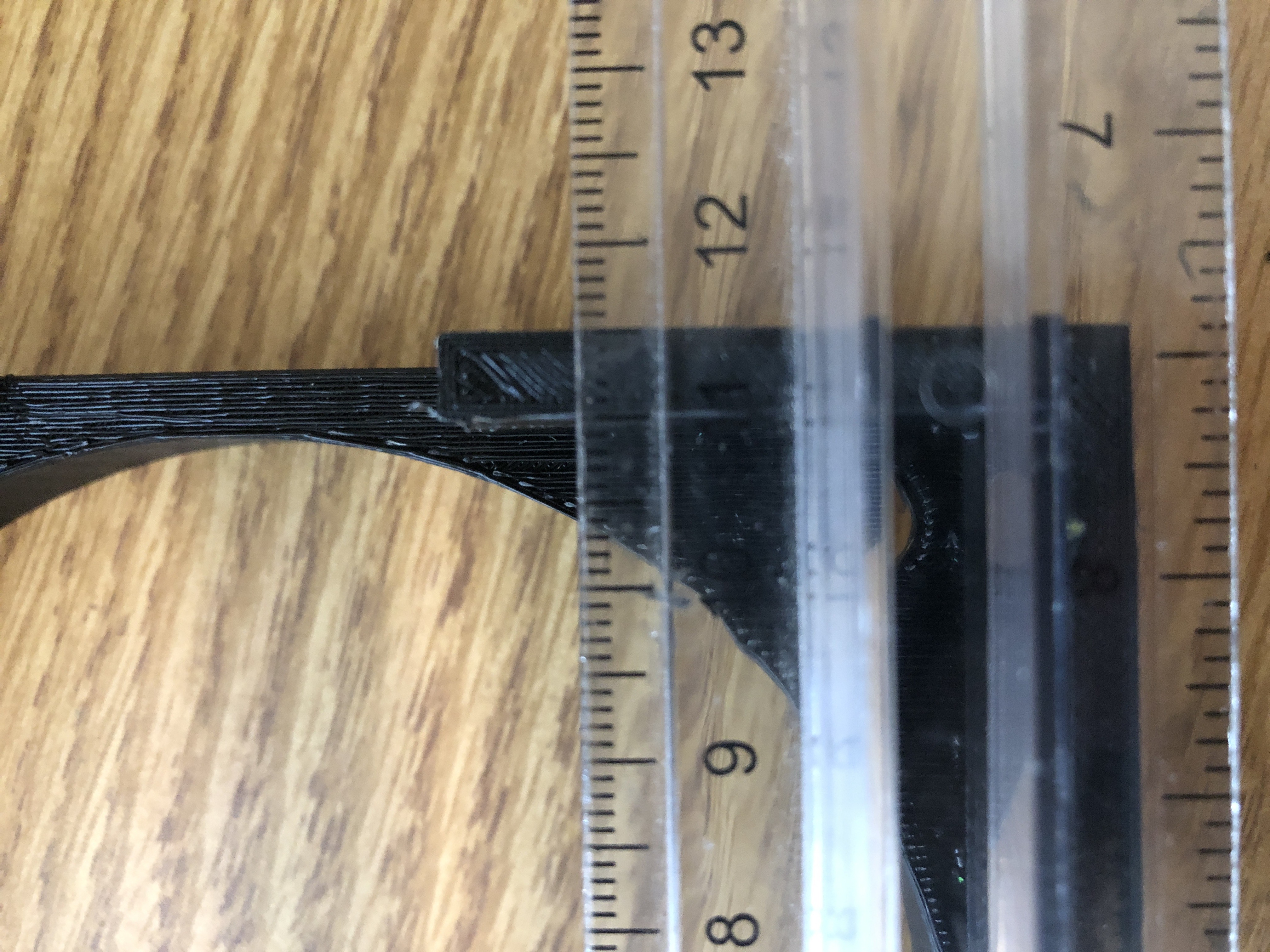

However, after clearing the scaffolding, I encountered an issue with the design’s size, as although both the drum’s internal cavity and the PCB measured 11 cm, the PCB was slightly too large to fit within the drum.

Since this size difference was less than a millimeter, I’ve been trying to sand down the interior of the drum enough to allow the PCB to fit. However, although the difference in size has shrunk from my efforts, the PCB is still unable to fit smoothly even after several hours of sanding.

I still believe this drum module is salvageable, as I was able to shorten the difference greatly, however I’ll need to dedicate more time to sanding or use a tool within TechSpark to assist me in doing so. Going forward, I plan on reducing the side walls of the housing from 5 mm to 3 mm for the other three drums, with all of the gained space going to the inside of the module. This may give me too much room on the drum’s inside, however it will be much easier to remove the additional space rather than to create more through sanding.

Regarding where I am in regards to our schedule, I am now slightly behind where I had hoped to be after carnival, as I was hoping to have a fully functional final module ready going into this week. However, This is not a major delay, as if I am able to perform a successful 3D print tomorrow with the new design I’ll only be a day behind where I expected to be. Other than that, the rest of this week will be focused on finalizing the drums and the Arduino code which communicates with them, so that hopefully I’ll be able to assist with other tasks going into the last few weeks.