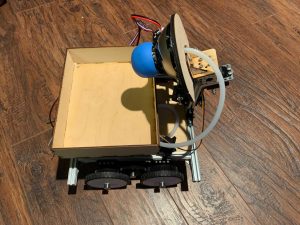

I built a robot using aluminum 80x20s for the frame. I used Rev Robotics parts for the computer, motors, encoders, motor controller, and wheels. Rebuilt the arm using 80x20s, used an aluminum for the housing of the wrist for the gripper, made a custom wood laser cut coupler for the gripper and the servo, and use a Rev robotics motor for turning the arm. A PID is used to keep the arm stiff at specific positions. Iterated through a variety of arm designs and added a gear reduction system to make the arm more powerful and have greater control. Laser cut a wooden insert for platform for the hardware of the robot. Got a different pump motor and a thicker tubing for greater suction on the gripper. Laser cut a wooden box to contain the picked up items. Modify and added code to existing robotics software packages to get the robot to move and to connect to each piece of hardware. Got computer vision code running on the camera mounted near the gripper so that a bounding box around an orange item can be found. Added joystick controls to drive the robot manually.