Significant risks for the project we managed this week:

-

Major Schedule Change Because of COVID-19:necessary integration between the hardware and the software parts are now hard to perform; thus, we decide to split the hardware and software parts and demo the functionalities of them individually. The communication between the hardware and software part (sending of flip signals) will be printed into the socket file and documented as well.

- Since now the hardware part and the software parts are isolated (we have difficulties working together/remotely), we cannot perform further integration between the software and the hardware parts.

- Now, when the flip point is detected by the software program running on our cloud service, a flip signal will be written to a file, which acts originally as the socket of communication between the hardware and the software.Â

- The real-time tracking information is printed and updated on the web page as soon as a new MIDI key is pressed by the user. A flip/repeat signal will also be printed when the flipping point or the repeat point is detected.Â

- The hardware parts (the mechanical flipper controlled by a Raspberry Pi) is de-scoped to an electrical demo and a CAD simulation. The user will be able to see the CAD simulation and the electrical demo that runs stepper motors to understand how the system was supposed to be integrated.

-

No further web simulation is going to be implemented anymore

- Since now we will have the hardware part (the mechanical page flipper) simulate the page flipping, and the web animation is not the focus of our project, we will no longer implement a web simulation (a flip page animation) because that is repetitive work.

- We will print flip point/repeat point/note being detected onto the webpage as proof of functionality.

Changes made to the existing design of the system:

-

The Software Part

- No real communication will be made between the software and the hardware part. All signals needed to be sent to the mechanical page flipper will instead be written to the socket file as proof of functionality.

- No web simulation of the page flipping is going to be implemented.

-

The Hardware Part

- Without the lab equipment (voltage source, multimeter, oscilloscope), we are unable to test if we are outputting the correct pulse signal to the stepper motor. We have ordered a plug-to-wall DC voltage source to power the stepper motor, but without testing tools, we are still risking frying the boards. Our electrical components will be shipped from the ECE lab to Tracy’s home next week.

- As a change of plan for the electrical demo, we decide to use the Raspberry Pi to control two stepper motors and one servo to do the intended motor control sequence when the flip signal is triggered. We attach a code review to analyze when and by how much each motor is signaled to run, to demonstrate the control algorithm.

- Without Techspark, we are unable to use laser cut nor 3D printers to fabricate new shafts and flippers. We currently have a first version wooden shaft and turner but no damper has been fabricated to prevent the shaft and flipper from wobbling. As a change of plan, we will just use the CAD simulation on Solidworks to demonstrate intended flipping motion. We will also not fabricate a physical stand to hold a music book because of the lack of tools.

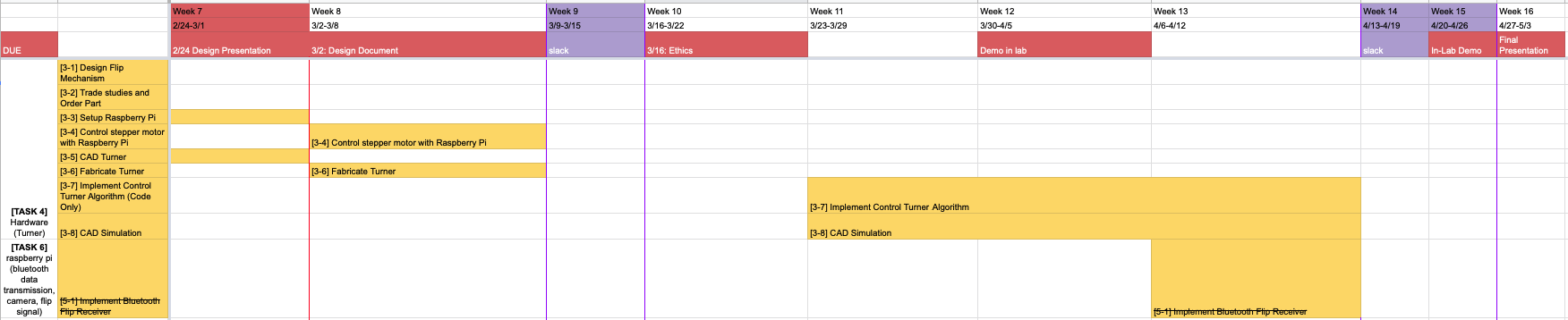

An updated schedule if changes have occurred:

0 Comments