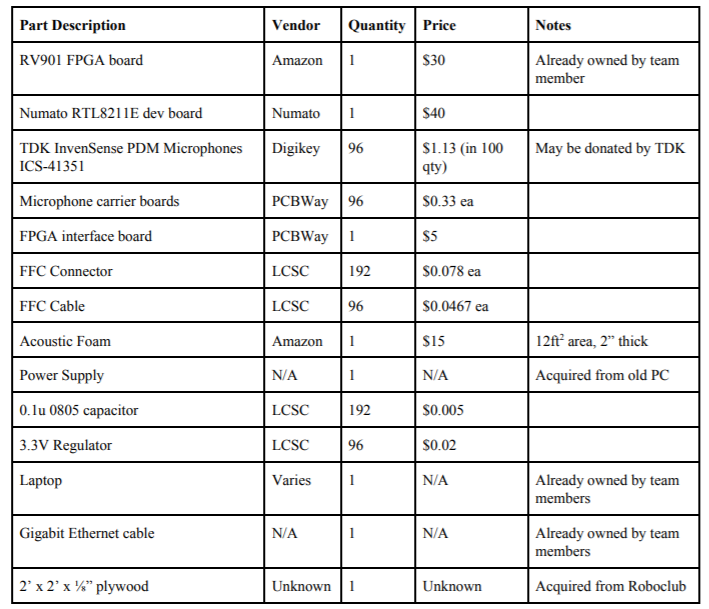

After talking to Patrick from TDK Invense, we were able go get 110 of the ICS-41351 from them. We’re very thankful for this because this would have been the most expensive part of the project, as shown below in the bill of materials from the design report:

If we were to order the microphones from Mouser, it would have costed $124.30. Now, we’re able to allocate that for monetary slack, as we may encounter situations during the build process that we may need to order new parts.

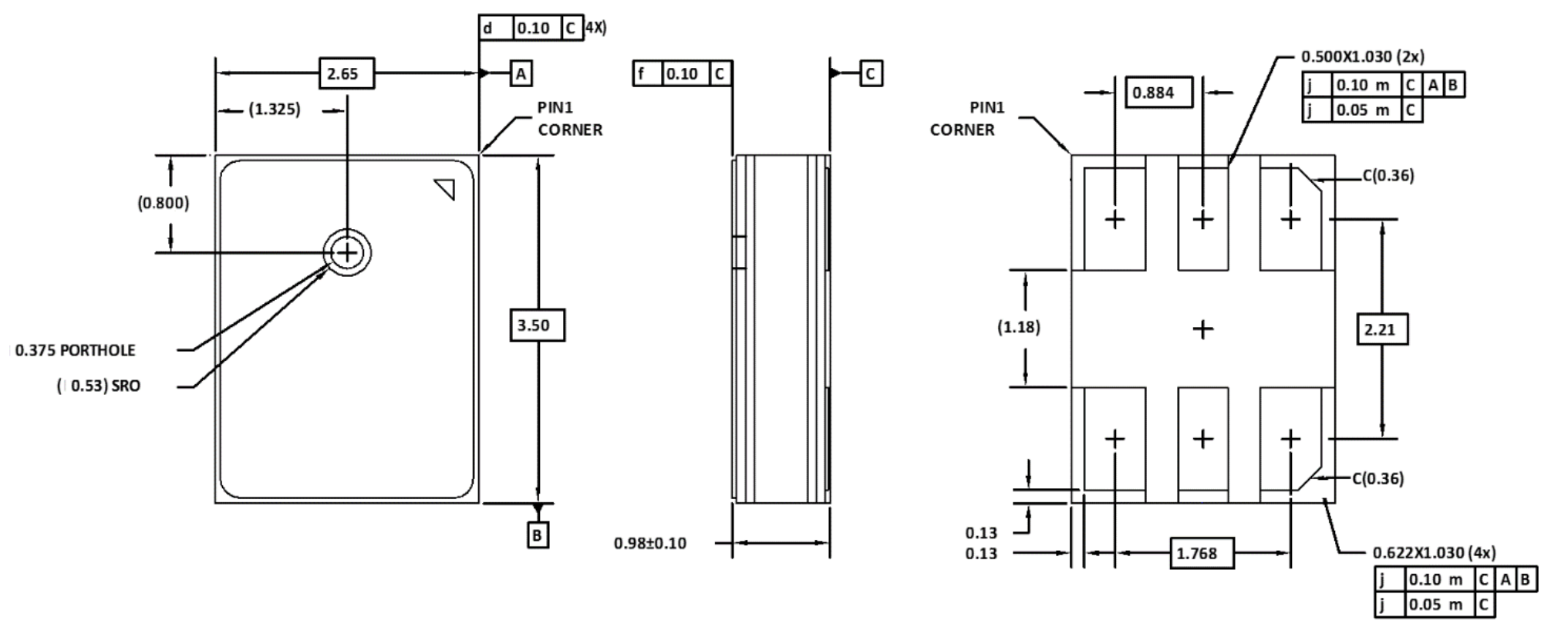

The candidates for the microphones were ICS-41351, INMP521, and INMP522. The latter two had slight better frequency response at the frequency of interest (5kHz and above), but we ultimately decided on the ICS-41351 because it had a footprint that was much nicer to work with.

It has relatively large pads on the bottom:

Because it has the microphone port on the top, the bottom solder pads are not constrained.

The INMP521 and the INMP522 however, have the microphone ports on the bottom, so it becomes much more challenging to solder properly, because the solder ring around the port has to be completely soldered for best acoustic performance, and it’s not easy to verify proper soldering when we do not have access to professional reflow tools.

The main task moving forward is to get the PCBs that John designed made and reflow them. I think it’ll be a fun challenge.