Individual Status Update

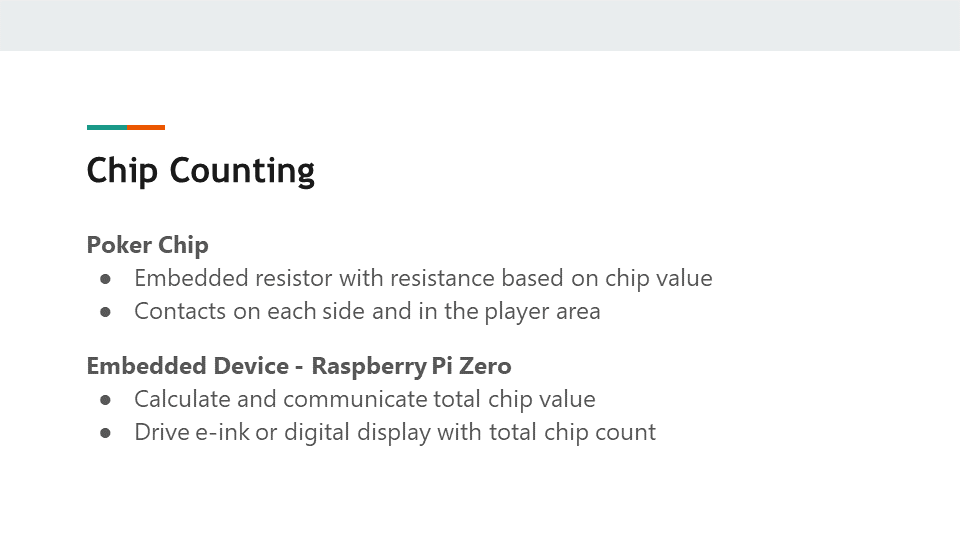

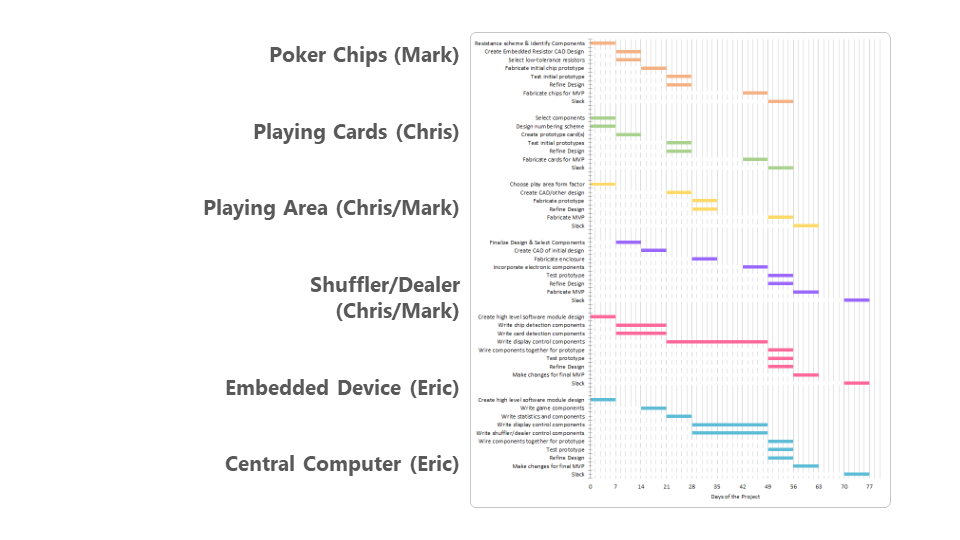

This week my primary goal was to fabricate an initial prototype for the embedded resistor poker chip and to design a CAD model of the shuffler and dealer prototype. Since the poker chips we ordered did not arrive this week I was unable to fabricate this prototype.

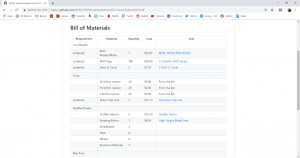

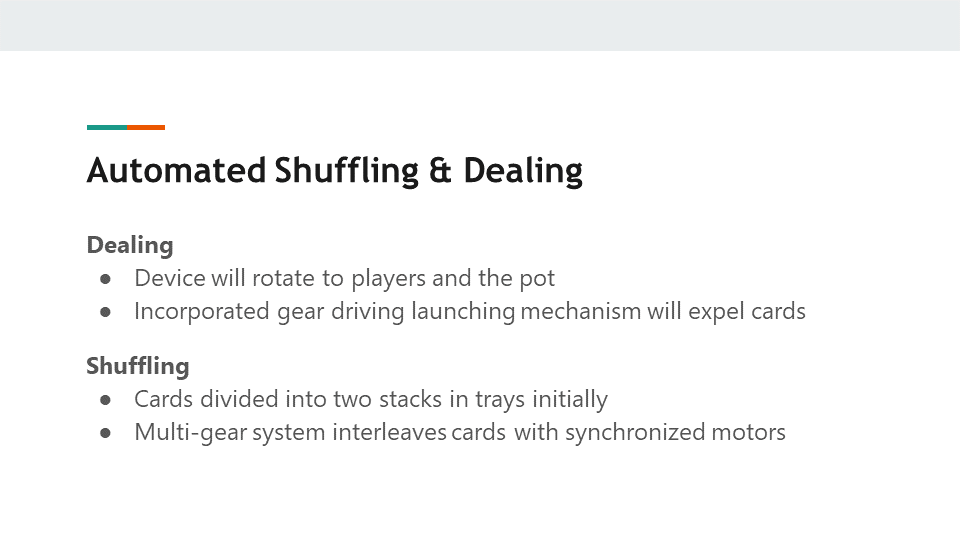

Due to this delay I focused more on the CAD model and selecting mechanical and electrical components which will be used to drive the automated shuffler and dealer. There are RC wheel 360 degree servo motors which come with attached wheels with rubber tread, which will provide a simple dealing mechanism, dealing from the bottom of the deck of cards. to shuffle the cards, high speed DC motors will be used to drive two sets of gears, one to grab one card at a time and push it towards the shuffling area, and the other to push the cards together in the shuffling area. I observed this gear design in existing shufflers which will provide better interleaving results than a system with only one pair of gears. The shuffler model is displayed later in the post, and Chris has the dealer model in his post.

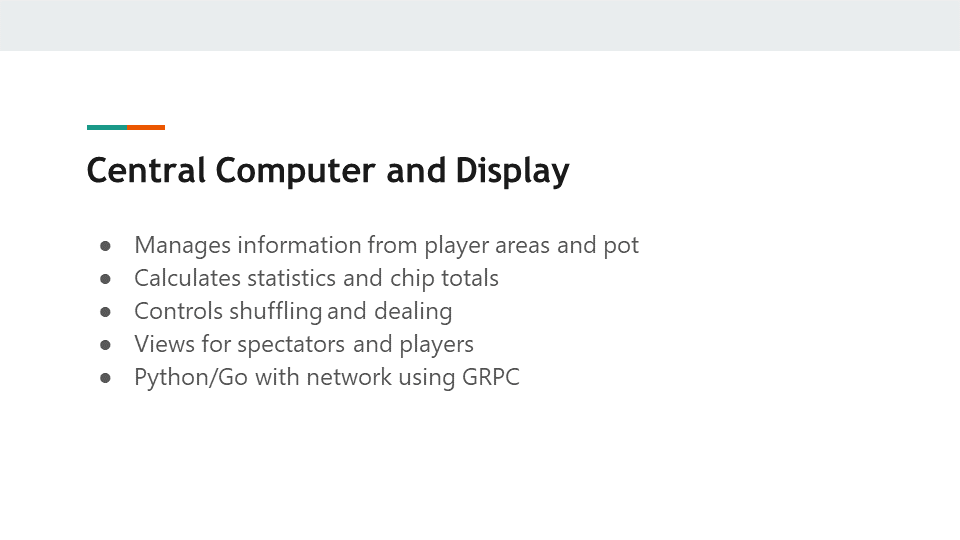

The motor driver used to drive all of these motors will be the L293D, which can drive two DC motors each and one servo motor each, so we need three, one for dealer rotation, one for card dealing, and one for the two high speed DC shuffling motors. I will work with Eric to ensure he is able to write software for these motors which will integrate with the rest of the game environment

I am on schedule for the playing area and the shuffler/dealer. However to catch up on the poker chips I will fabricate and test the initial prototype so I can move onto finalizing the design in a couple of weeks.

Next week I intend to CAD a model of the full playing area, as we will know the physical design for all components in the playing area. I also will fabricate the poker chip prototype for the $5 chip and test this prototype. If that goes smoothly I will fabricate the $50 and $10 chips.