Ethan:

This week I continued work on the wireless system, however our focus pivoted to the high level systems required to make the headphones work. I discussed this with my teammates at length to make sure we were all on the same page and could code together.

Unfortunately, my responsibilities during the carnival season, as well as my 349 lab partner dropping has had a decidedly adverse effect on the amount of work I got done last week. I am behind on wireless optimizations, and my current tests still put me at a maximum of 600,000 bytes per second. While that number meets (and exceeds) the bandwidth requirements of our project, it is not fast enough for the latency requirements. We have have an effective bandwidth an order of magnitude higher than the bandwidth required for a single stream because as we make more hops, our maximum ELS (effective link speed) goes down.

Given the pending date for demos, I plan this week to pivot my focus to making sure the Audio playback is smooth and (hopefully) integrating the software with the physical hardware that should arrive sometime this week.

Michaela:

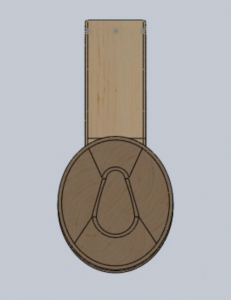

Though I was fairly ambition in my plans for this week in my last status report, there were a few unexpected occurrences that deterred me from accomplishing all that I wanted to do. We have decided as a group that rather than printing the headphones now, we will wait until all the components are assembled and testing is done, as this might effect our budget and thus lower the allocated printing budget. After discussing the higher level software more with Ethan, we have come up with a system that will run on top of the scheduler of the ESP32 in order to properly pass along resources to our necessary operations and run them as efficiently as possible. For this reason, I reworked the FSM and UI code a bit and started working on creating the necessary aspects of this system, such as the tags that will be assigned to each scheduled task. Other than that, due to issues arising involving Buggy filming and overestimating my energy level after these days of work, I was unable to complete much else. With this winding down and the final in lab demo approaching, I am hoping to have this code and test cases prepared by the end of next week.

Winston:

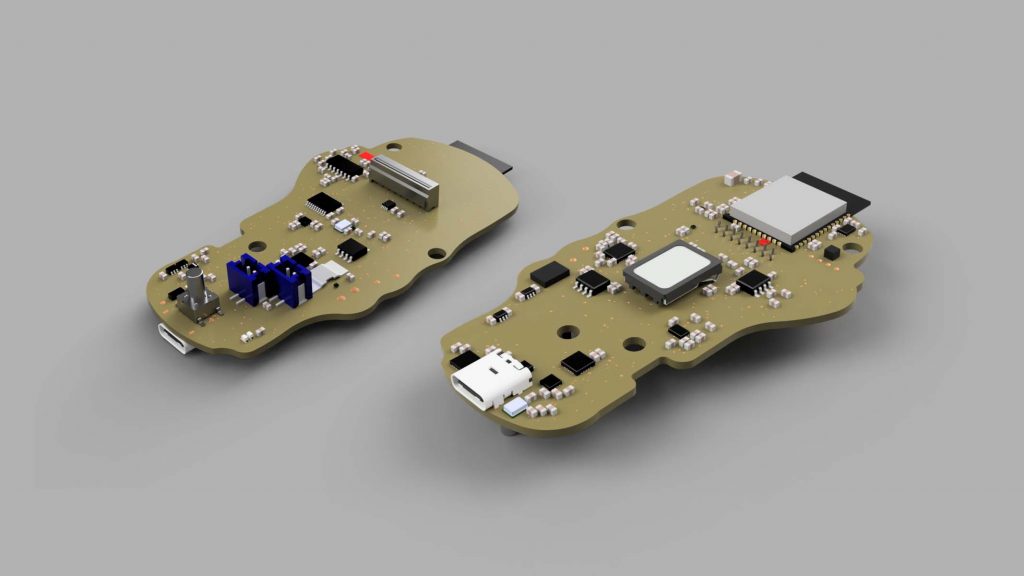

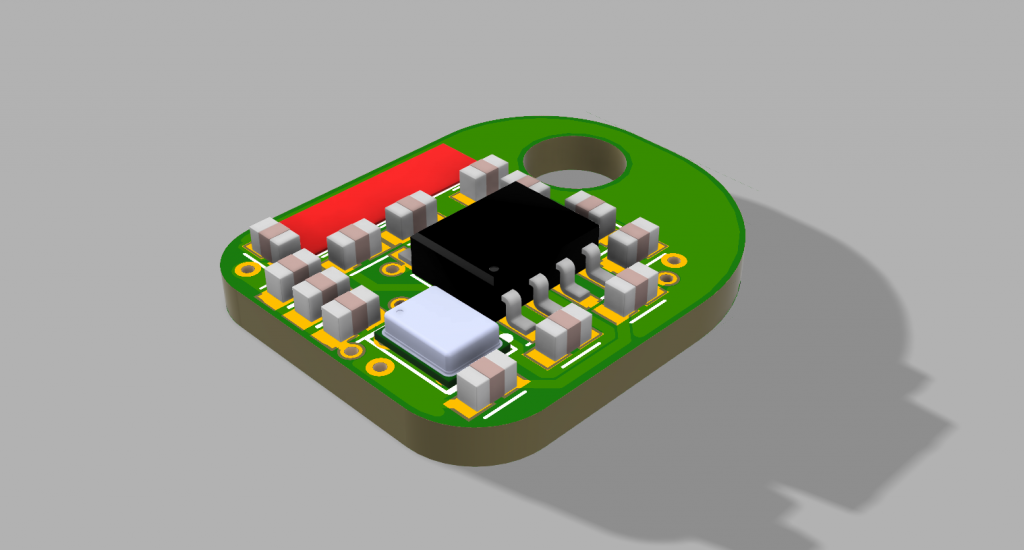

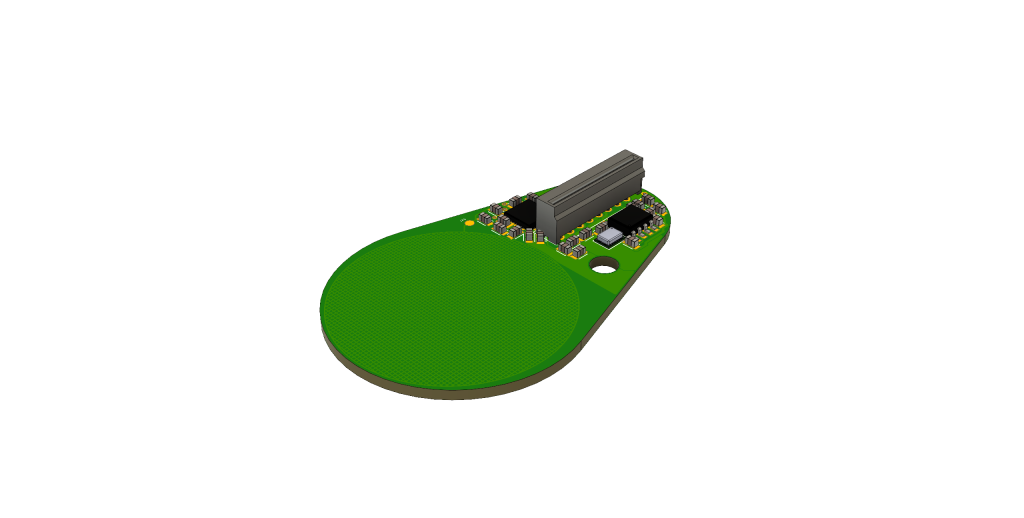

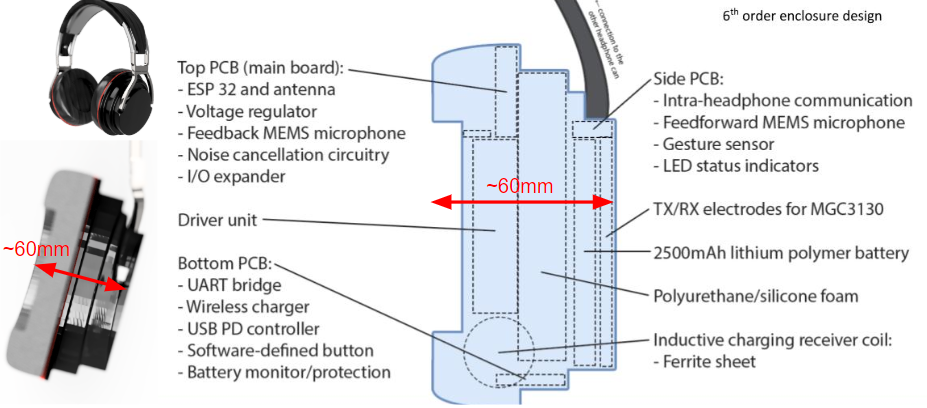

This week, per Prof. Tamal’s request, I updated the layouts of PCBs with stricter design rules, bumping minimum clearances from 3.5mil to 5mil, minimum trace width from 3.5mil to 6mil, and minimum distance between drill and copper from 0.2mm to 0.25mm. More than 2000 traces have to be moved manually; these more stringent design rules are largest satisfied, with few exceptions, and thus minimize the critical area in these boards.

The endeavour to implement firmware continues. The push in schedule is compensated by pulling more time out of Carnival to work on this project.

Team:

As a team, we are currently trying to prepare for the inevitable debugging that will need to take place when we integrate our components. Overall, we are trying to build test cases and scenarios, such that we can mitigate the issues that will arise once this occurs.

Moreover, as a team, we set ourselves a soft deadline for the completion of the software system to be the time that hardware is shipped and assembled, which is expected to be Apr 21.