Accomplishments

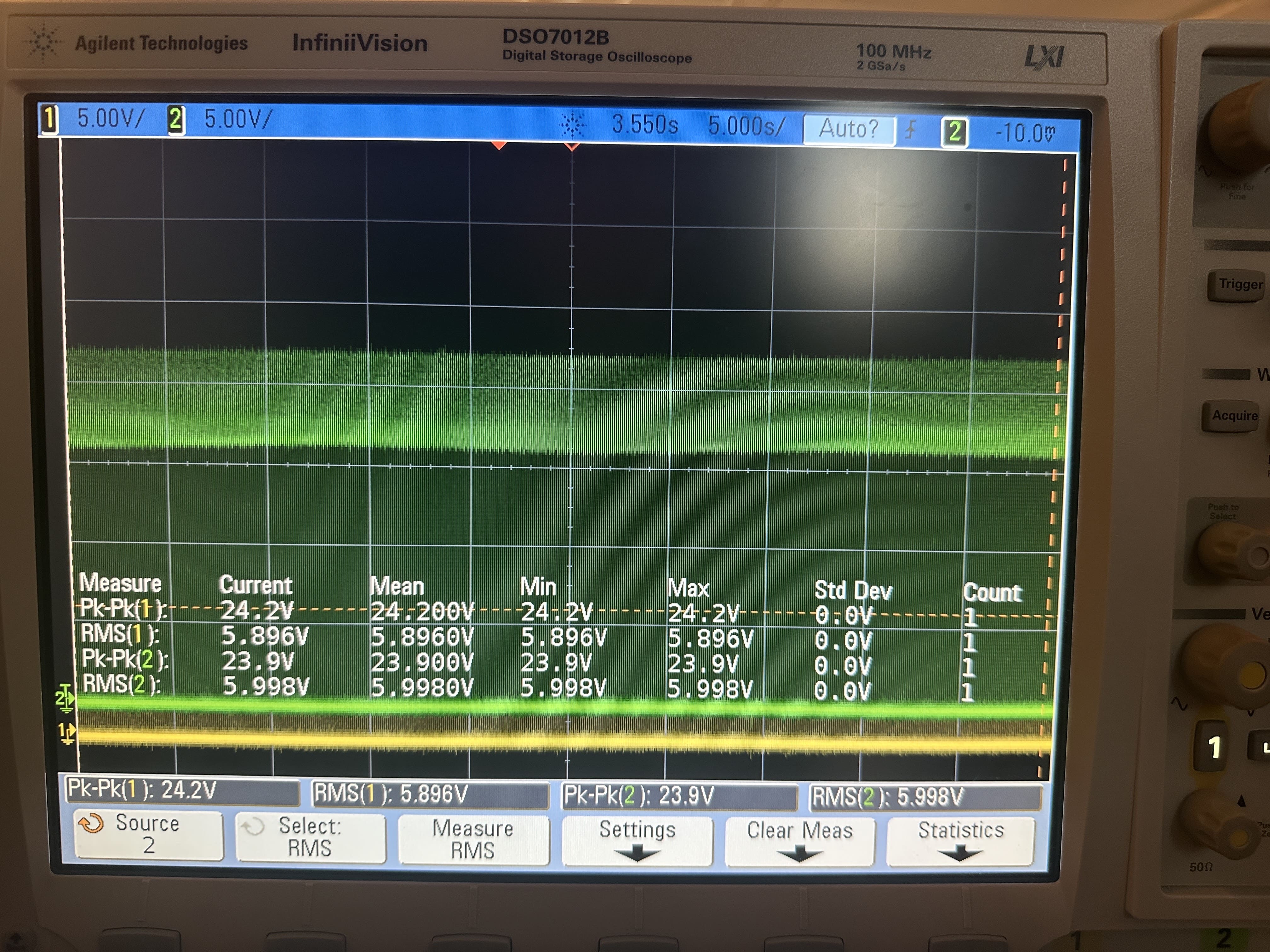

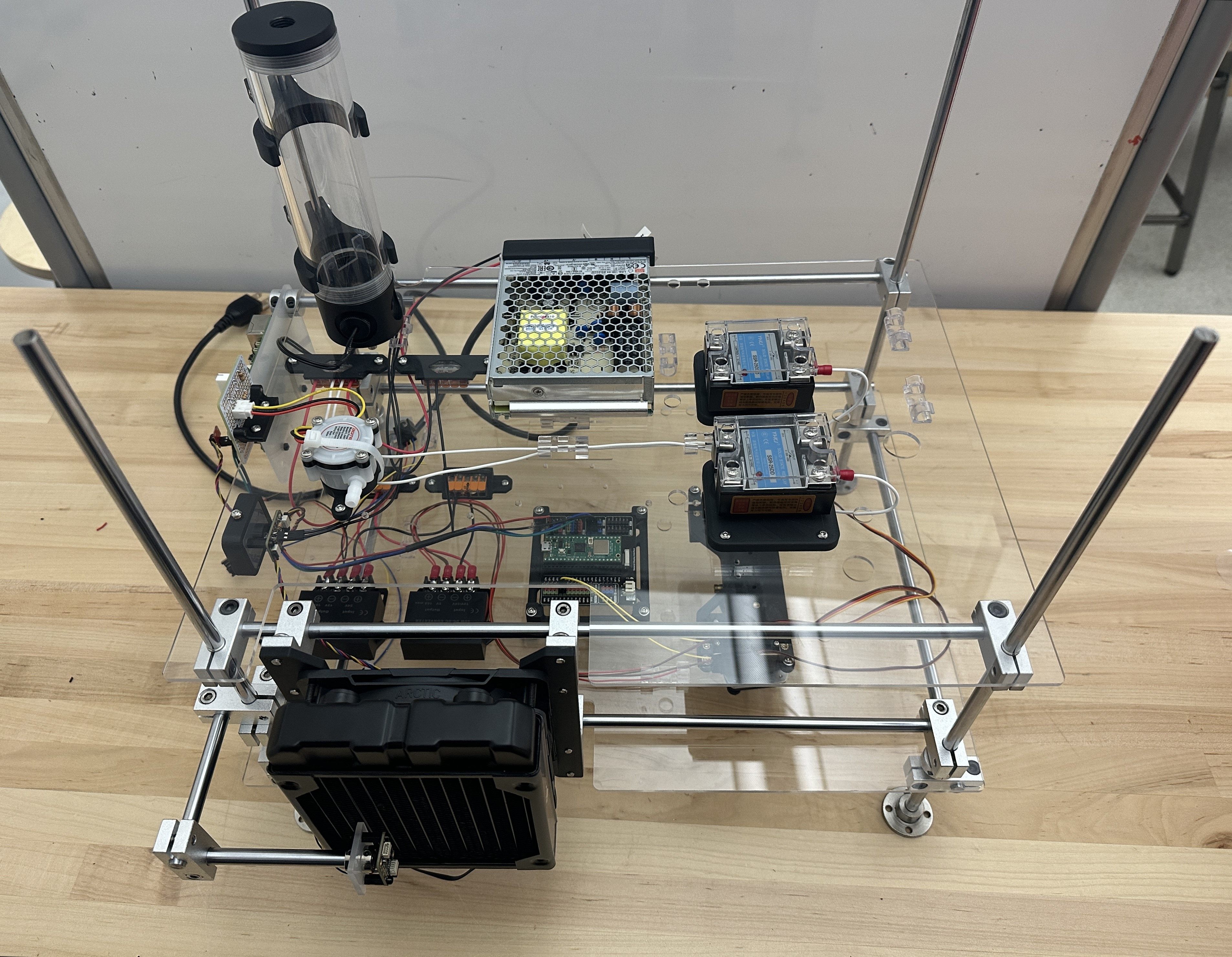

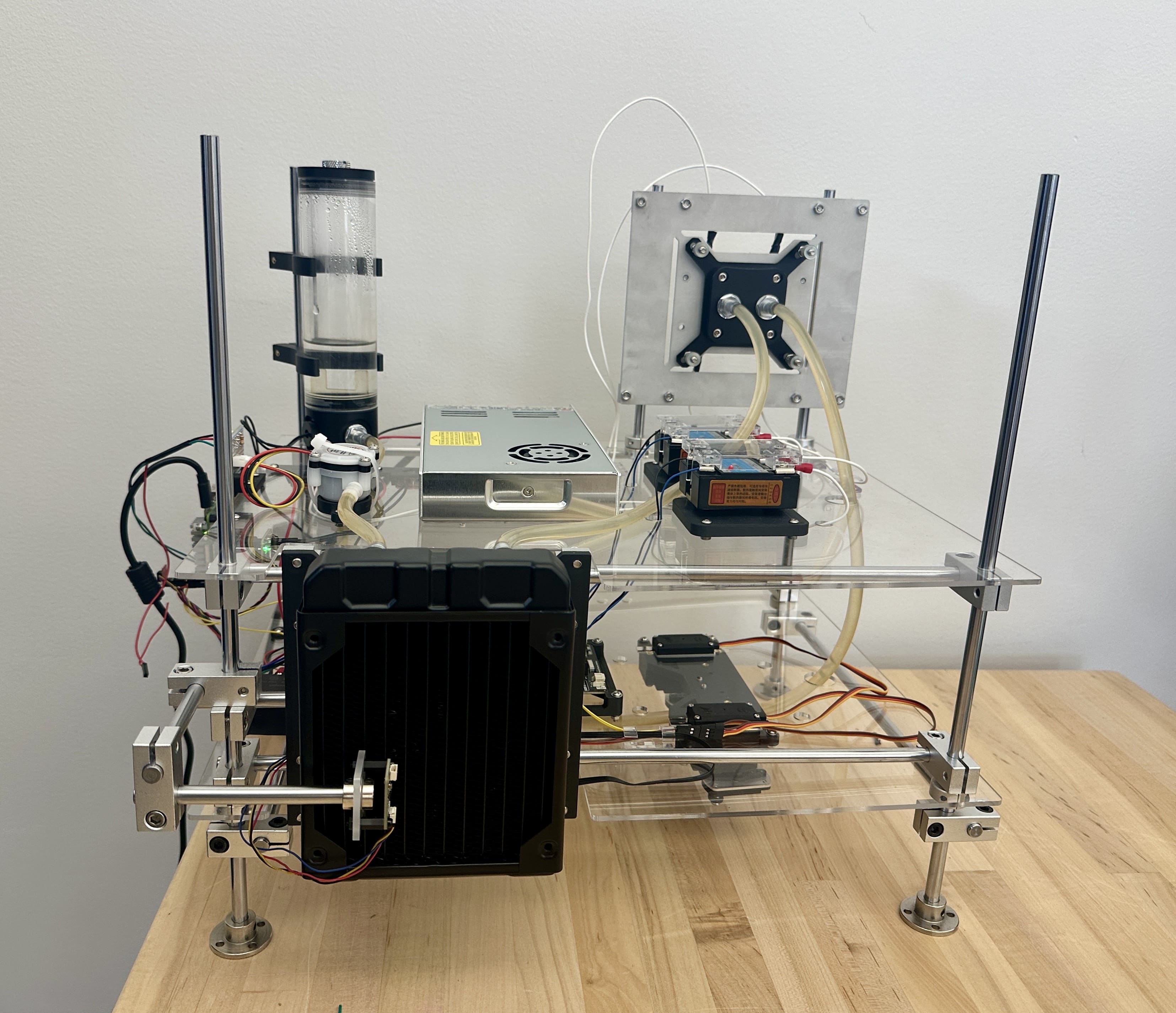

- Hardware Upgrades: Replaced previous PSU with higher-wattage power supply for full-load heater testing

- Testing & Data Collection: Began running automated test patterns including ramp up, ramp down, spike, and multi-level hold profiles

- Completed synthetic data collection patterns covering full power range (20-80W)

- CPU Power Trace: Collected power trace from a laptop using HWiNFO to generate realistic workload profile for testbed

Significant Risks

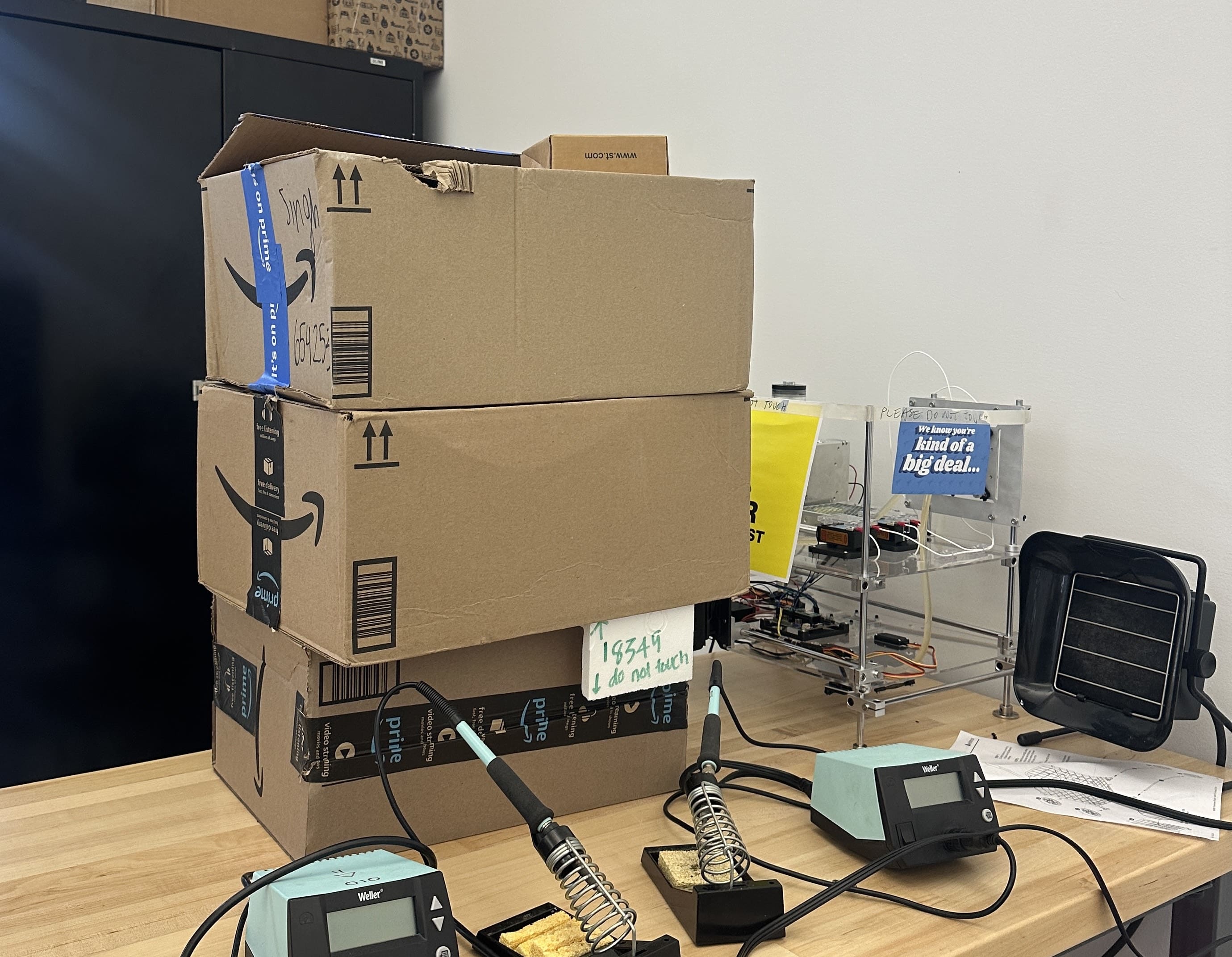

- Interference from Other Classes: Embedded systems class is storing large boxes directly in front of testbed’s intake fan area

- Obstructions may alter airflow, reduce heat dissipation, and affect temperature sensor readings

- Risk mitigation: Hope that embedded will move boxes soon

Design Changes

- No major design changes this week

Schedule Changes

- Project remains on track

- Synthetic data collection now complete for normal operation

- Running real traces