UART Pi5 to Pico Communication Code

- Began writing code for UART communication between Pi5 and Pico

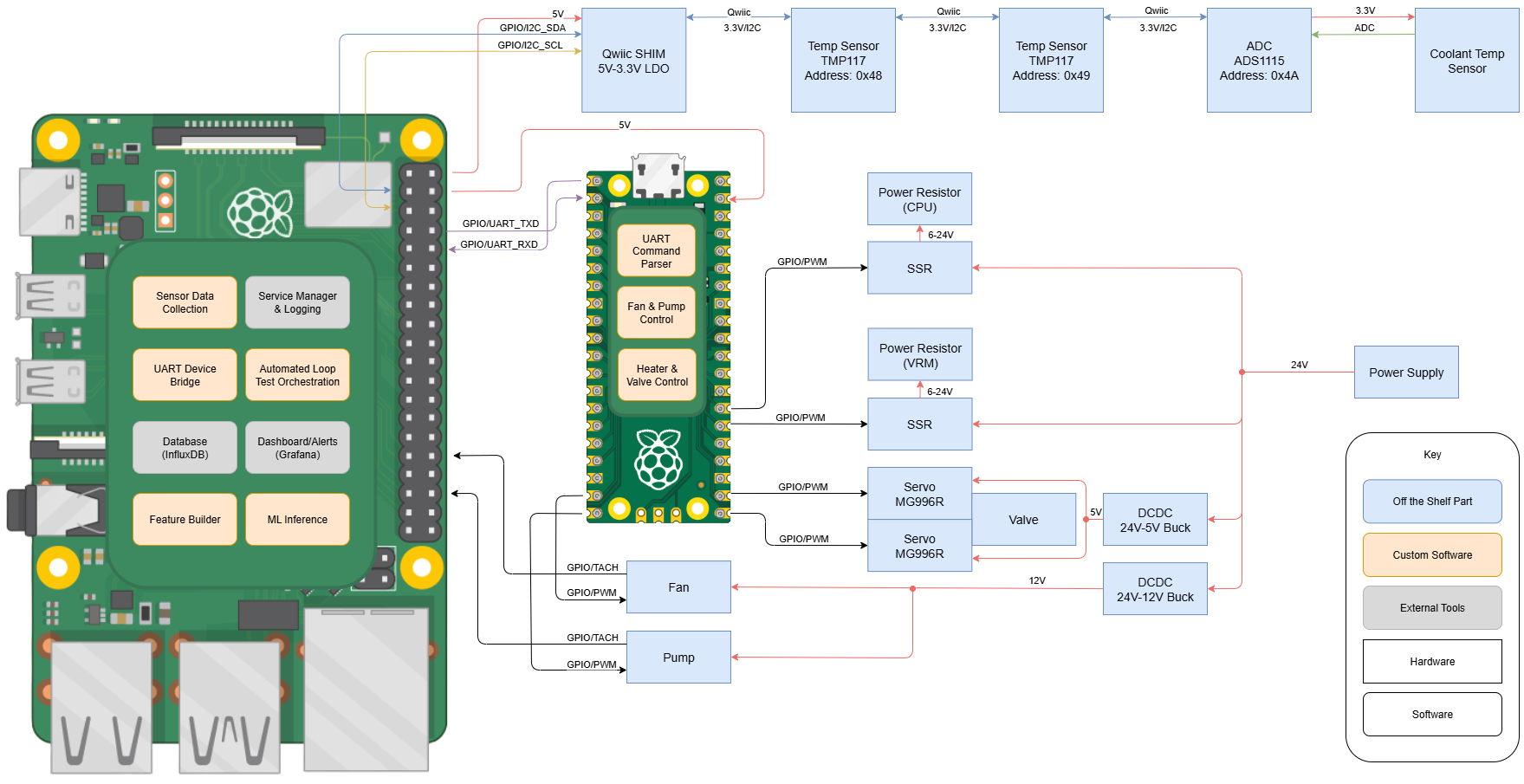

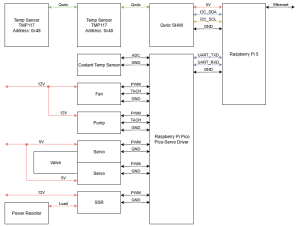

Design Report and Research

- Focused on finishing the Design Report and polishing all sections for submission

- Strengthened justifications for system and model design tradeoffs

Schedule & Progress

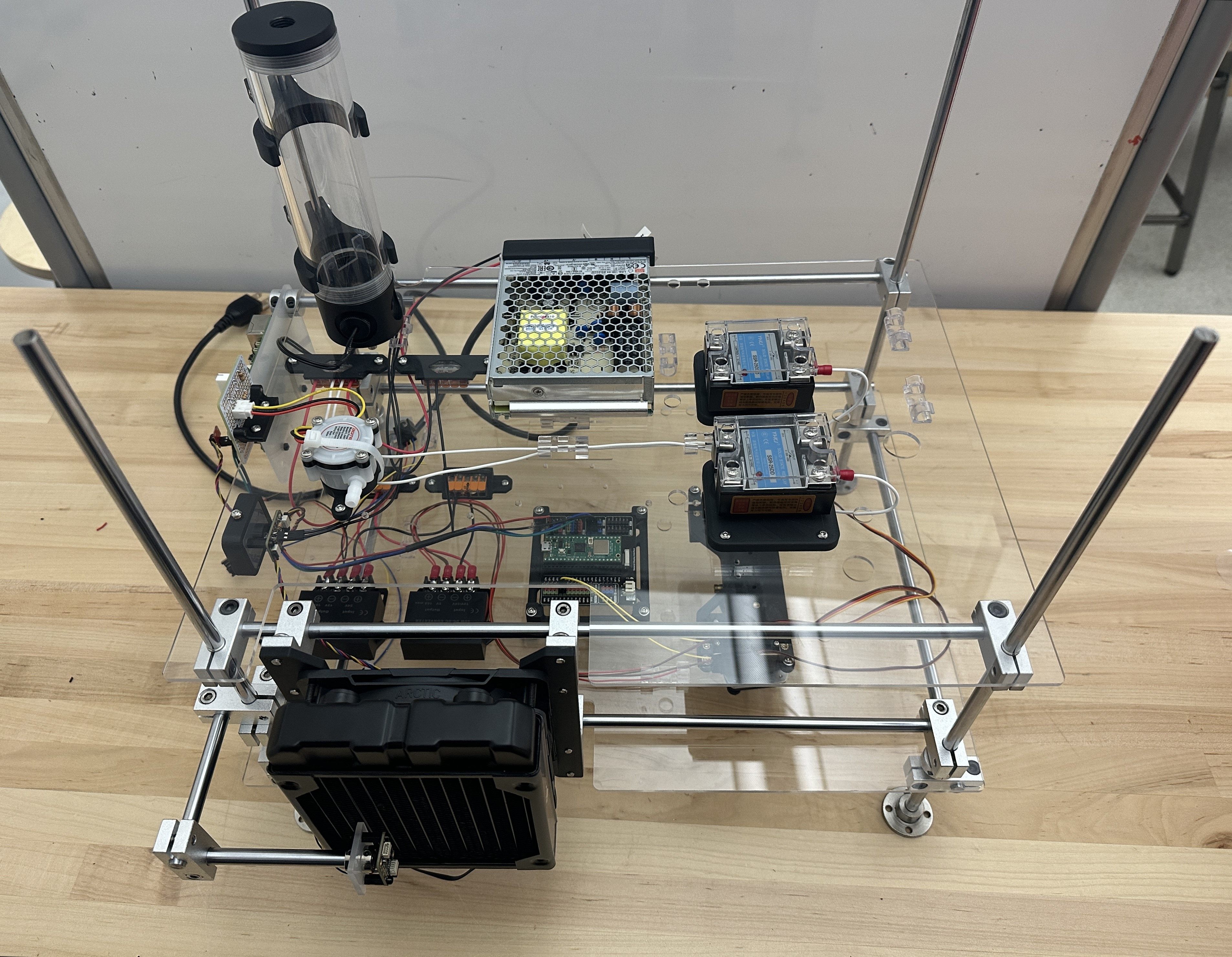

- On schedule:

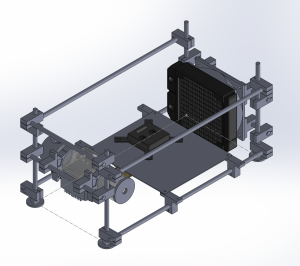

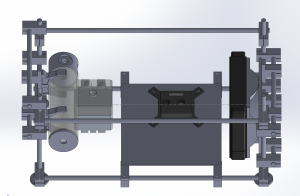

- All off-the-shelf parts have arrived

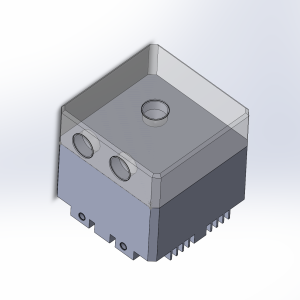

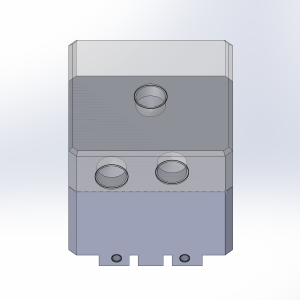

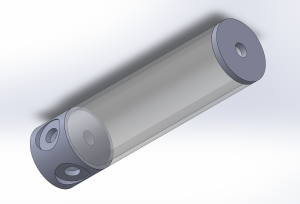

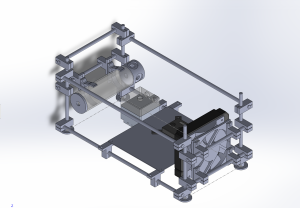

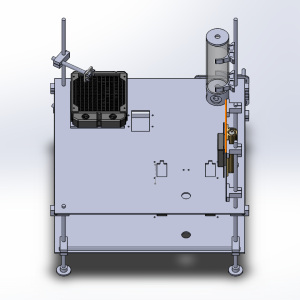

- Custom part dimensions verified and adjusted to match real measurements

- Plan to send out custom cut parts after Fall Break

- Behind schedule:

- UART Pi5-Pico communication delayed due to debugging

- Minor delays from Pi5 setup and network configuration issues

Next Steps

- Begin setup and partial assembly of testbed

- Continue debugging UART communication

- Assist with sensor integration and PWM control code