Accomplishments

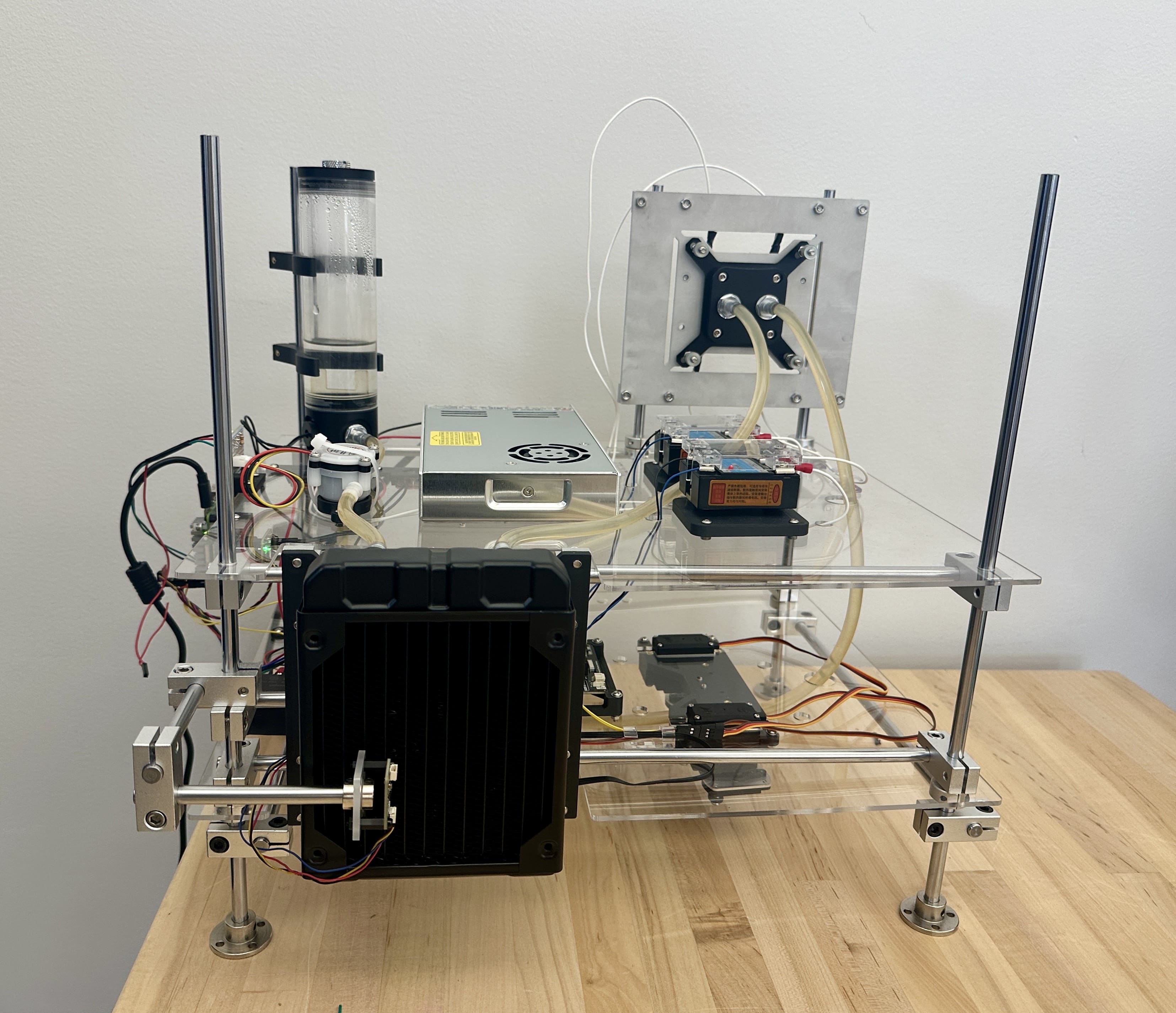

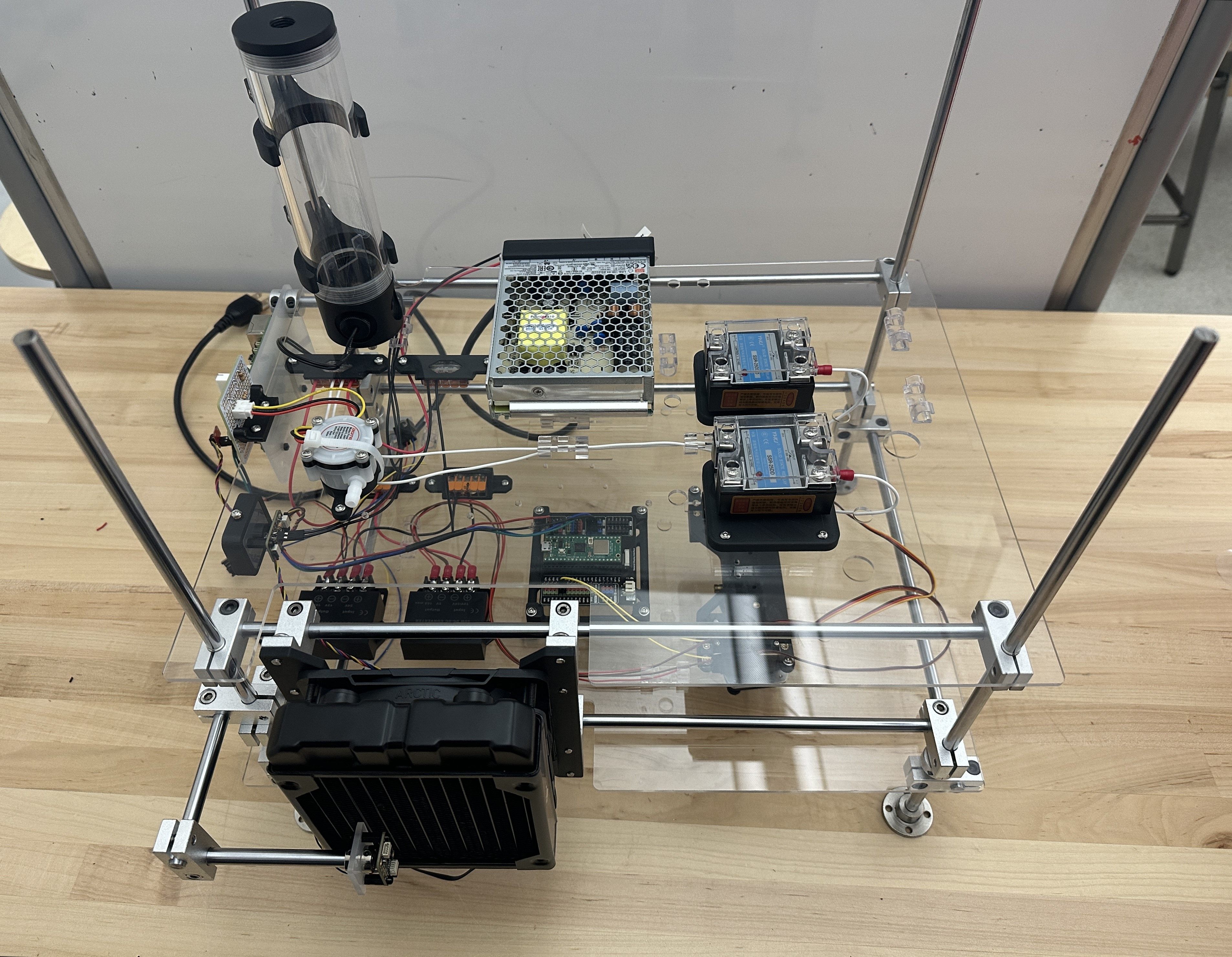

- Testbed coolant flush: Flushed out cooling loop because of yellow fluid and contaminants

- Data collection: Recollected normal dataset due to ambient temperature drift and coolant loop differences affecting inference

- ML model development: Retrained regression and autoencoder using updated normal data

- Updated autoencoder architecture to use delta temperature features only to lessen effect of ambient temperature changes

- Final deliverables: Started planning Final Report, Video, and Demo

- Took video of testbed for Final Video

- Split up Final Report sections

Significant Risks

- Model sensitivity: Since model is designed to detect small deviations, small drifts in ambient temperature, water levels, and other factors can cause the model to alert an anomaly

- Switched to delta temperature only features (no absolute temperatures)

- Tuned thresholds based on power levels

Design Changes

- No major design changes this week

Schedule Changes

- Project remains on track

- ML model tuning in progress

Testing and Results

- Servo Valve Flow Restriction Test: Ran servo through different PWM duty values and measured flow rate to map duty value to flow rate reduction

- Result: Mapped duty value to flow rate reduction with fit equation

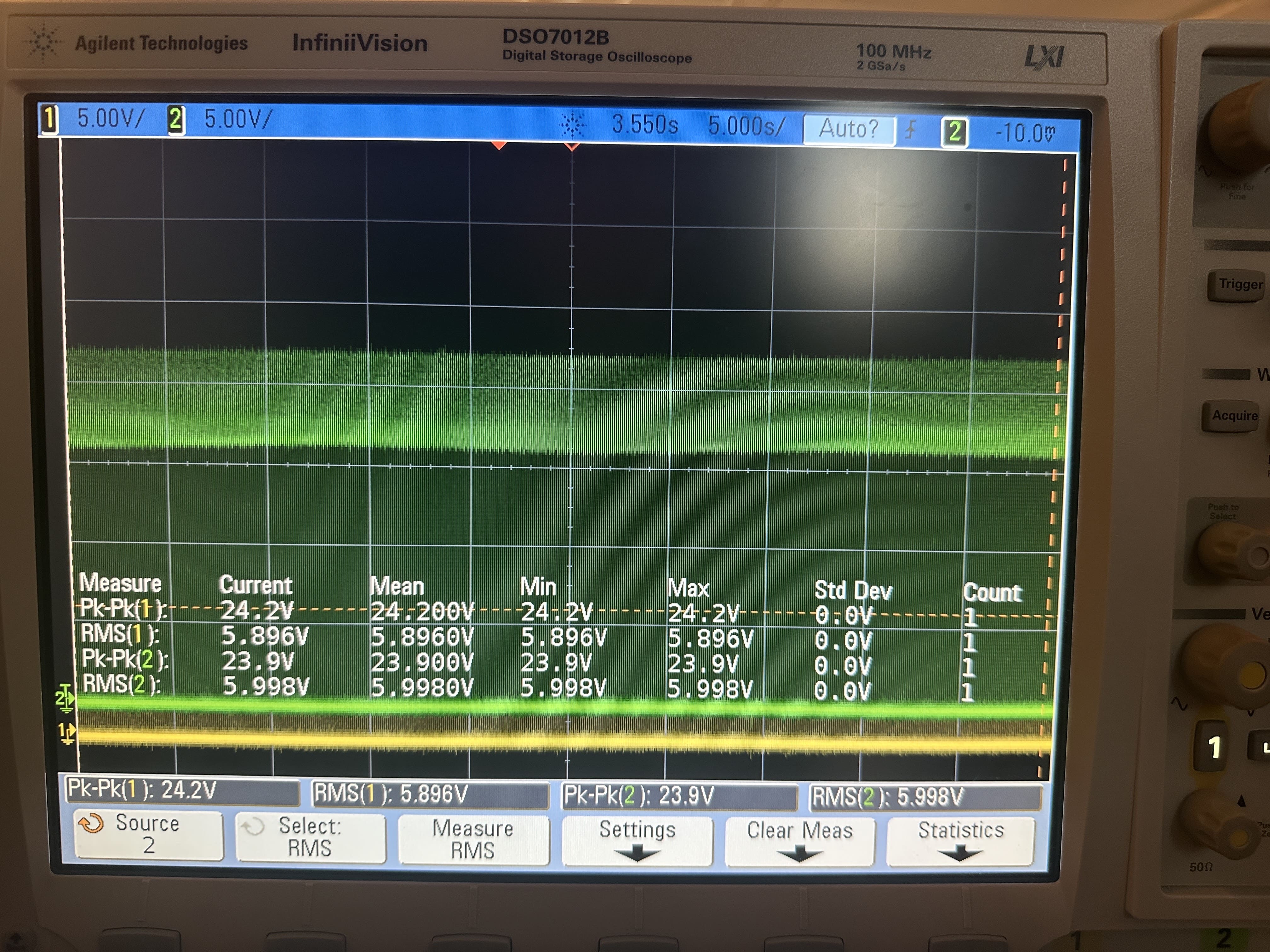

- Heater / Power Delivery Test: Applied PWM values to the SSR and confirmed heater power using RMS voltage measured on oscilloscope

- Design Change: Found that power supply rating too low and had to purchase higher wattage power supply (300W)

- Result: Commanded power is accurate to actual measured Vrms

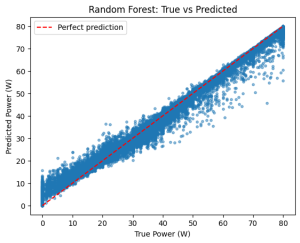

- Regression Model Prediction Accuracy Test: Compared predicted vs. measured CPU power on normal datasets

- Design Change: Replaced original linear regression model with a Random Forest after benchmarking several models

- Result: Random Forest achieved RMSE = 2.53 W

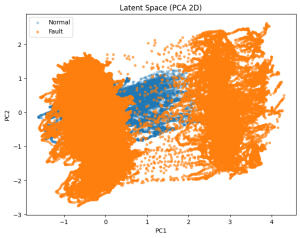

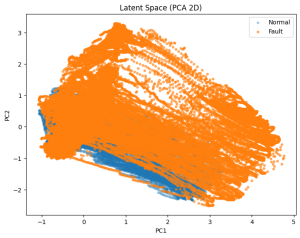

- Autoencoder Model Latent Space Test: Examined latent space separation between normal and fault windows and measured FPR and FNR

- Result: Model successfully differentiates normal from fault data

- FPR: 0.38%

- FNR: 0.64%

- Result: Model successfully differentiates normal from fault data

- Classification Model Accuracy Test: Evaluated classifier performance on distinguishing flow faults vs. power faults

- Result: Model successfully classifies flow fault and power fault

- FPR: 0.00%

- FNR: 1.06%

- Result: Model successfully classifies flow fault and power fault

- Latency Test: Measured timing from inference start to alert generation

- Result: Model meets 1s latency requirement

- Regression = 141 ms

- Autoencoder = 363 ms

- Classifier = 9 ms

- End-to-end = 825 ms

- Result: Model meets 1s latency requirement