This week, I was unable to attend 18500 because I was very sick all week with the flu. I made sure to stay in contact with my team while under these unfortunate circumstances. I communicated regarding post-demo and updates to our model training/progress. This allowed me to stay on track for next week after recovering from my illness to assist with all items leading up to the final demo and presentation.

Our schedule is currently on track and we plan to focus on the final presentation and ensuring our model training stays on track for final demos.

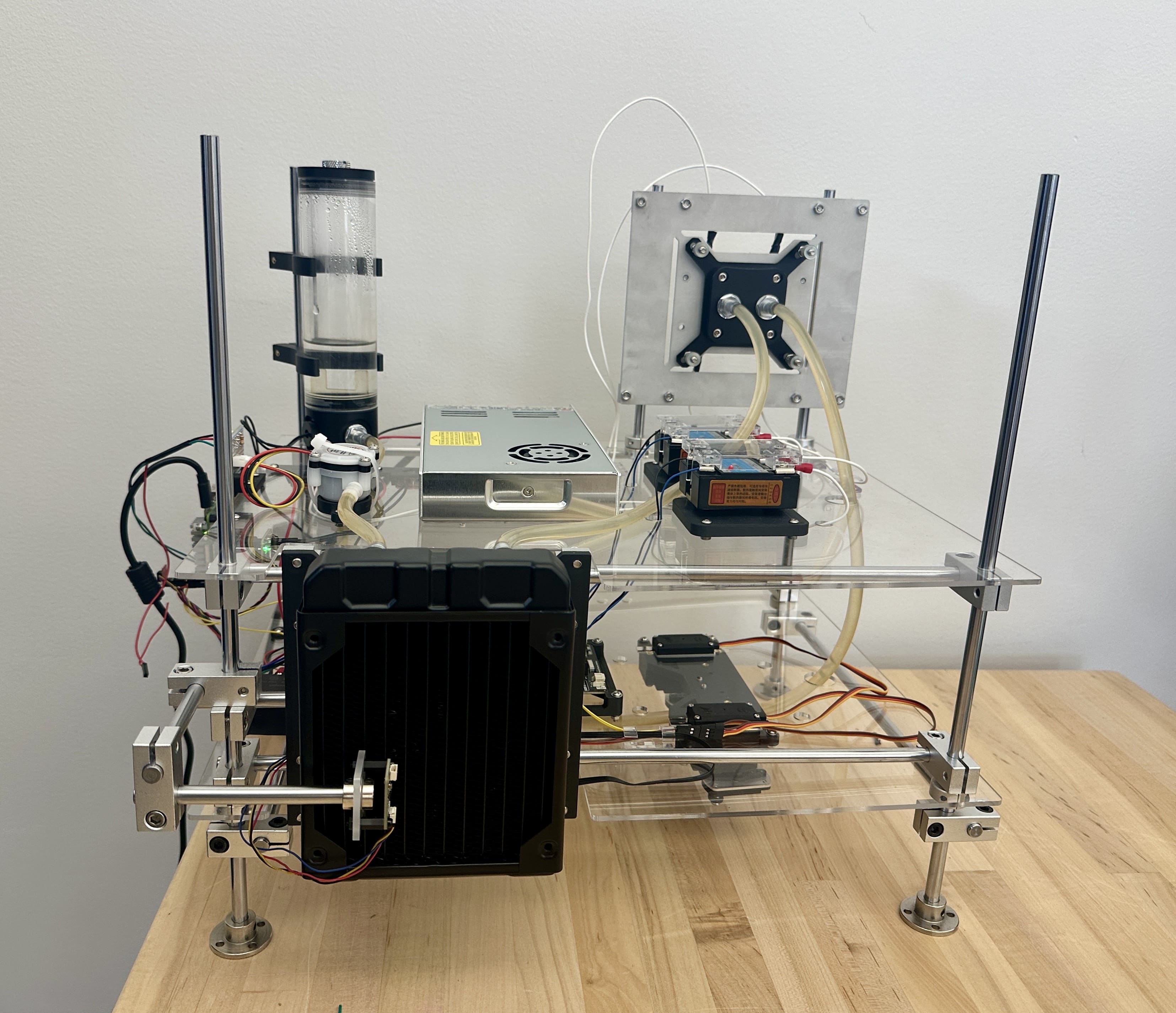

For my portion of AnomAIy, I was responsible for learning various new platforms to develop, debug, and integrate all items regarding the Raspberry Pi Pico. This involved learning how to use the Pico, MicroPython, and the Raspberry Pi for Pico to Pi communication. These platforms were all completely new to me and required me to utilize my prior experience with microcontrollers to learn and develop on new platforms. Some learning strategies used to acquire this new knowlege included watching youtube videos detailing Pico setup, reading articles written for MicroPython newbies, and researching forums that detailed debugging strategies when unusal errors occured with integration.