Selected specific STM32 chip (STM32H563RI) and configured peripherals.

Selected clock modulation IC that works with EPC660 and EPC21603 (single ended + LVDS differential, respectively).

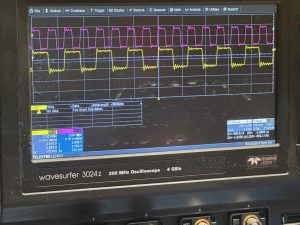

PCBs of MCU+interface and control board schematics underway, along with verifying design through simulations.

Design presentation preparations and communication of necessary requirements across modules and firmware.

No pushbacks in schedule nor changes in design.

Part A(Sid):

The Illuminator can be beneficial for many aspects of public safety and welfare. Underwater robots are required in many critical applications such as water tower maintenance and underwater shipwreck recovery operations. By increasing the resolution, cost-effectiveness, and field of view of these robots using a visible light ToF camera, loss of life can be prevented by increasing the effectiveness of recovery operations. In addition, water towers can suffer from corrosion and leakage of poisonous materials. By accurately inspecting scale and buildup on the inside of water towers with robots, these dangerous growths can be identified earlier before they leach into supplies.

PartB(Claire): Not applicable. Our sensor system does not ignite social activities in any way as it does not have a human to human interaction in its design. It does not emphasize cultural awareness or political campaigns, and is not intended for any of those purposes.

PartC(Gleb): The main application of our underwater ToF camera is to provide volumetric vision capability to AUVs doing close-range manipulation. In general, AUVs are expensive, with prices in tens or hundreds of thousands dollars. Therefore our sub-$1000 sensor will constitute only a small fraction of the vehicle cost.

Currently, the only feasible alternative for close-range 3D vision underwater are stereo-cameras. A high-quality stereo-pair cost is typically $500 or more. For example, the cameras used for stereo-vision on TartanAUV’s Osprey submarine cost around $3500 each. Therefore, our system is very competitive in terms of cost. Additionally, a ToF sensor has certain advantages over stereo-pairs, which we discussed in our design proposal.