Weekly Status Report Question (Team):

ABET #6 discusses develop and conduct appropriate experimentation, analyze and interpret data, and use engineering judgment to draw conclusions …

List all unit tests and overall system test carried out for experimentation of the system. List any findings and design changes made from your analysis of test results and other data obtained from the experimentation.

Back-end Tests

- Uncontracted and contracted braille function test: Trying 100 randomly generated strings and comparing it with the output of Braille Blaster app (state of the art translation software)

- Result: 100% accuracy

- Testing to see how many responses were in database according to https://progressivegrocer.com/100-iconic-brands-changed-grocery

- Result: 97% hit rate, 100% relevancy

- Timing test to create the database: converting it from a csv to the database multiple times and averaging that time as well

- Result: 36.7 s

- Timing database lookup time

- Result: .132 second

- Timing how long it took to query for each above test

- Result 5.32 s

- Solenoid instruction testing: creating a sample input with unique numbers instead of just 0s and 1s and compared it to the expected output.

- Based on the results of these tests, we determined that the database was the faster option for our product. In addition, we determined that our webscraping algorithm was satisfactory.

Front-end Tests

- User testing: ran user testing session with 4 users to test user satisfaction with front-end interface and embosser device on a satisfaction scale from one to ten

- Questions asked?

- How easy was it for you to navigate the web-app?

- Based on your experience, how likely are you to continue using this web app for your needs?

- Did you receive sufficient and timely feedback when you entered a product name or typed notes?

- How satisfied are you with the overall usability and functionality of the web app?

- How efficient was the search functionality in retrieving relevant instructions or information based on the product name you entered?

- Based on your experience, how likely are you to continue using this web app for your needs?

- How well did the web app handle errors, such as incorrect product names or failed searches?

- How effective were the accessibility features (such as screen reader compatibility) in making the web app usable for you?

- How clear and understandable were the instructions provided by the web app?

- How easy was it for you to use the embossing device?

- How effective were the tactile cues on the box (including surface textures and braille instructions)?

- How would you rate the paper registration experience?

- How would you rate the portability of the device (weight, size, etc.)?

- Results: 4.55/5 user satisfaction

- User feedback: different button names, placement of buttons

- Questions asked?

Hardware Tests

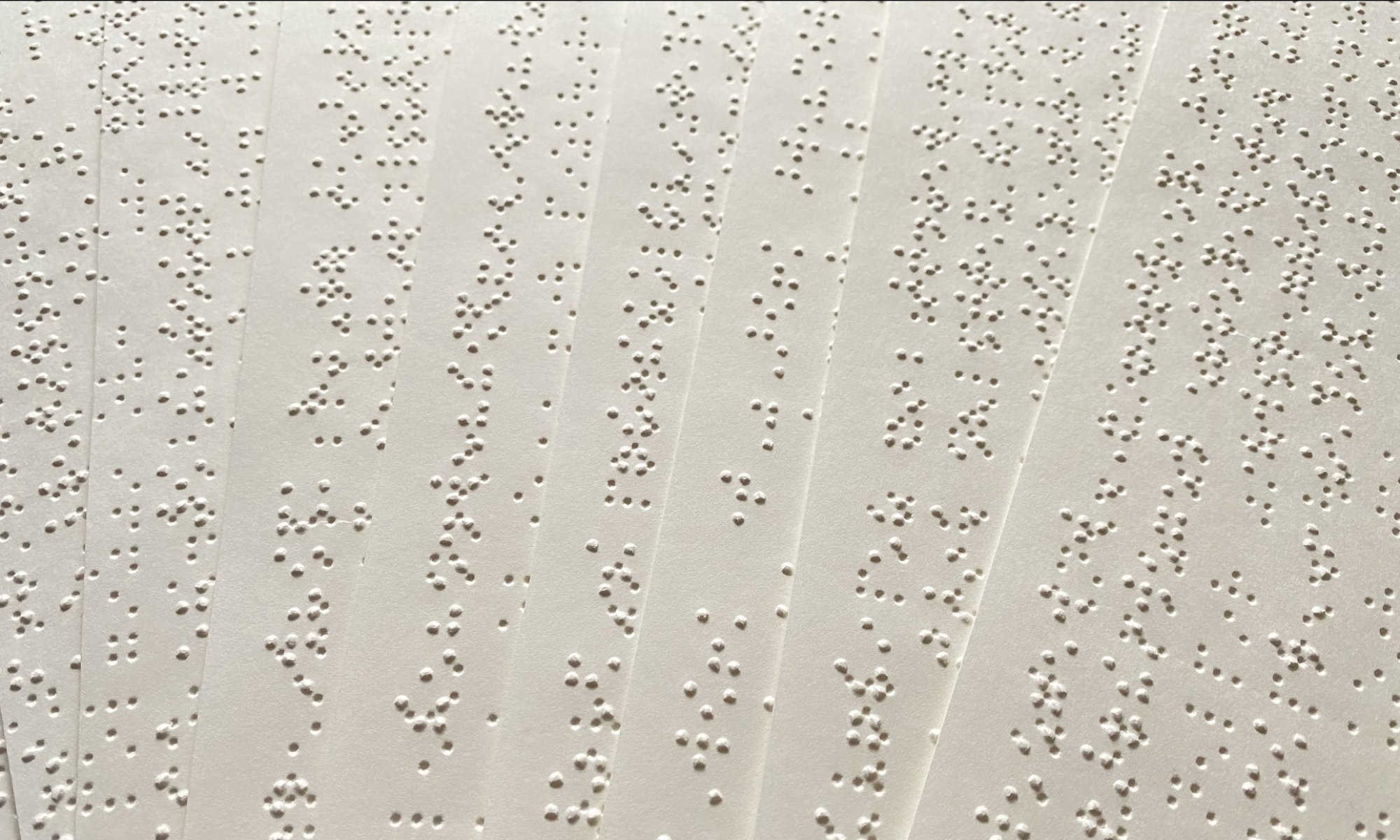

- Tested quality of embossed braille (size and location) by inputing random combinations of solenoids into arduino code

- Design changes: downsized from 4 to 2 solenoids to gain more control over the tensioning of the paper and distances between the solenoids. Changed various spacing settings within the arduino code

- Design changes: change in stepper motor driver to achieve better precision with the stepper motor

- Photo-resistor testing: Varied values given to the photo resistor to test light sensitivity for paper registration.

-

Design changes: swapped from a 10k to a 4.7 k resistor to get more dynamic range on the ldr when we closed the top of the embosser, added an LED to pair with the ldr because when the lid is closed there is virtually no light in the embosser

-

Integration Tests

- Tested communication between the RPi and Arduino using LEDs to represent solenoids: sent 30+ sample inputs to the RPi from the web-app and tested for accuracy in solenoid representation. Test results influenced how serial communication was set up in the Arduino code.

- Tested full pipeline on various notes input combinations such as “abcd”, “llll”, “dfdfdf” that have distinct braille shapes to test quality of output.