ABET #6 says … An ability to develop and conduct appropriate experimentation, analyze and interpret data, and use engineering judgment to draw conclusions

Now that you are entering into the verification and validation phase of your project, provide a comprehensive update on what tests you have run or are planning to run. In particular, how will you analyze the anticipated measured results to verify your contribution to the project meets the engineering design requirements or the use case requirements?

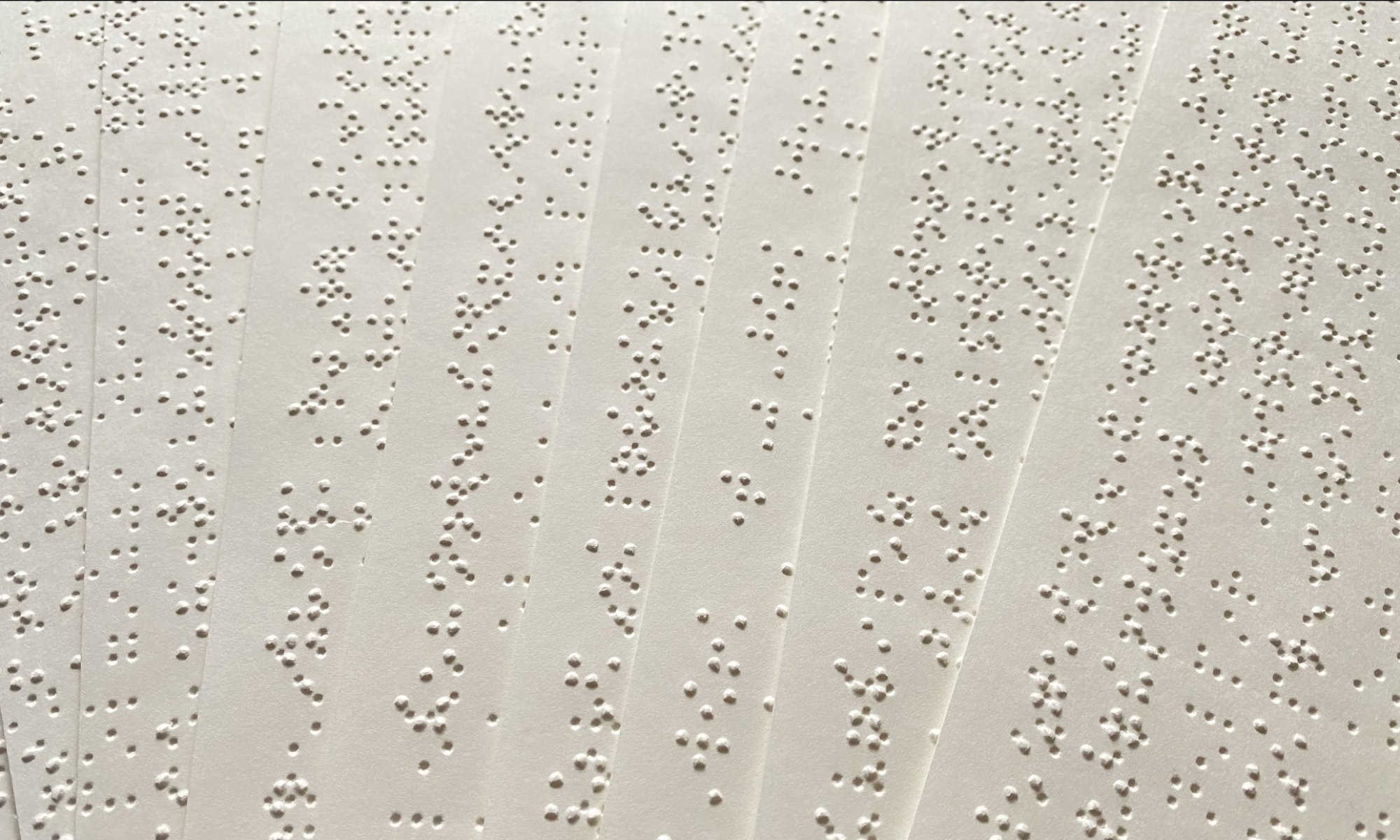

I’ve worked on the X/Y gantry system and the circuit design components of the project. The relevant requirements for me have to do with tolerances printing the braille and speed.

Mechanical Precision & Functionality: I will test to ensure that the placement of the gantry system allows for embossing, that the x gantry isn’t too close to the compliant surface. I need to test various compliant surfaces and select the best one. So far I have tested felt, styrofoam, and 1 grade of low density foam.

Usability: I need to test that our user can be able to determine which side the paper goes in quickly. I have created a texture that will be tested at this week’s LAMP demo, and we will get feedback there on its effectiveness.

PCB Testing: The PCB is set to arrive next week, and we will need to verify that it does all of the things we think it will do.

IR Sensor Placement: IR sensors are susceptible to reflective surfaces, so we need to do testing to see what position will not get bad signals from reflecting off of the acrylic. This is important to our requirement tests because the IR sensor actually verifies that the paper has been placed in correctly.

Weekly Update:

I redesigned the PCB to be Arduino compatible given our team’s recent decision to switch the hardware over to be controlled by an Arduino, and communicate over UART to talk to the Raspberry Pi. The PCBs will be arriving just before Thanksgiving, so we will be able to test them during the break.

I ran into issues with the stepper motor circuit this week during demo. The current limiter circuit appeared to be not functional, and I did not have the tools I needed to do further testing during the demo.

Next week, I plan to build the Y axis component. I reached out to Zach from Ideate, and he will be bringing be a broken printer to take apart and get the rollers out of.