Accomplishments

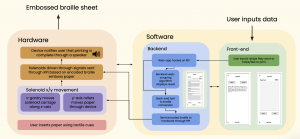

This week, I primarily focused on completing the design presentation, working on the design review document, ordering parts/refining our bill of materials, and I began work on the web app. I spent time at the beginning of the week refining our design presentation by creating informative block diagrams and figures and cleaning up the slides.

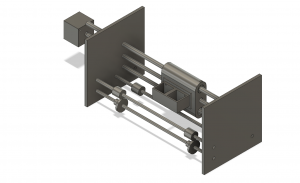

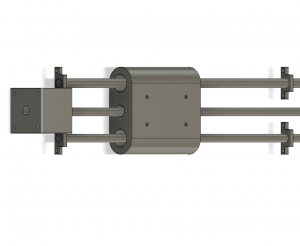

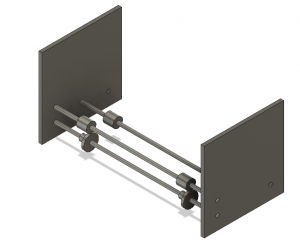

I also began work on the design review document and transferring information from our design presentation into the document. I also refined the BOM and decided on some of the specific parts I would need for the solenoid system. I ordered the solenoids and I will begin ordering more components (such as screws, diodes, mosfets) later in the week.

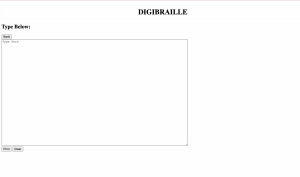

I also began working on our web-app. This is my first time using Flask and html, so I spent time reading through documentation and learning about how to use Flask. After I read through documentation and felt more acquainted with the framework, I began implementing our wireframe web-app design into the actual web-app. I am currently focusing on having the basic layout of the web-app complete. After that I will focus on specific design choices for its implementation based on accessibility documentation to make it most accessible to our users. My progress is a bit slow at the moment as I get more used to Flask and html, but currently I have created home page and two separate pages for each feature of our website. I have attached to example screenshots of my progress so far. The user input on this page will be sent to the back-end of our code.

Is your progress on schedule or behind? If you are behind, what actions will be taken to catch up to the project schedule?

My progress is a bit behind schedule at the moment. I have been out of town since Thursday, so I have not been able to devote as much time as I would like to working on the front-end. In addition, because I am out of town, I haven’t been able to work on my hardware component. In the next week, I will spend extra time to finish up the basic layout of the web-app so we can begin user testing, and work with Becky to design PCBs to send out during fall break. I also note that I emphasized finishing the solenoid circuit and encasing design, and testing prior to my weekend out of town so I would be ready to work on PCBs the following week.

What deliverables do you hope to complete in the next week?

In the next week, I hope to finish up and refine the basic layout of the web-app for user testing and finish up testing the solenoid system for PCB design by the end of the week. I will also complete the design review report, which I predict will take a good amount of my time this week.