What did you personally accomplish this week on the project?

I created a CAD model of the x/y gantry, which honestly was quite a process because I had to convince myself the hard way CAD’ing our design from scratch was actually better than modifying a 3D printer.

Last Saturday I opened up Solidworks in the lab at Ansys and started downloading mechanical pieces to create the x/y gantry, and I noticed that the McMaster Carr linear rail and bearings were quiet expensive. I figured there was a cheaper way to source the mechanical components in the machine. I looked on Amazon and I found a 135$ 3D printer. I figured that and a ramps board would be a quick way to get to MVP. We were advised against pursuing this route.

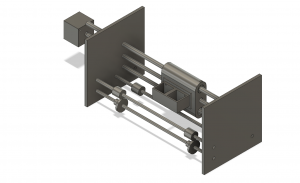

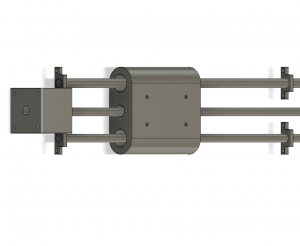

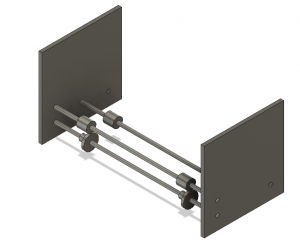

Here are some screenshots of the CAD.

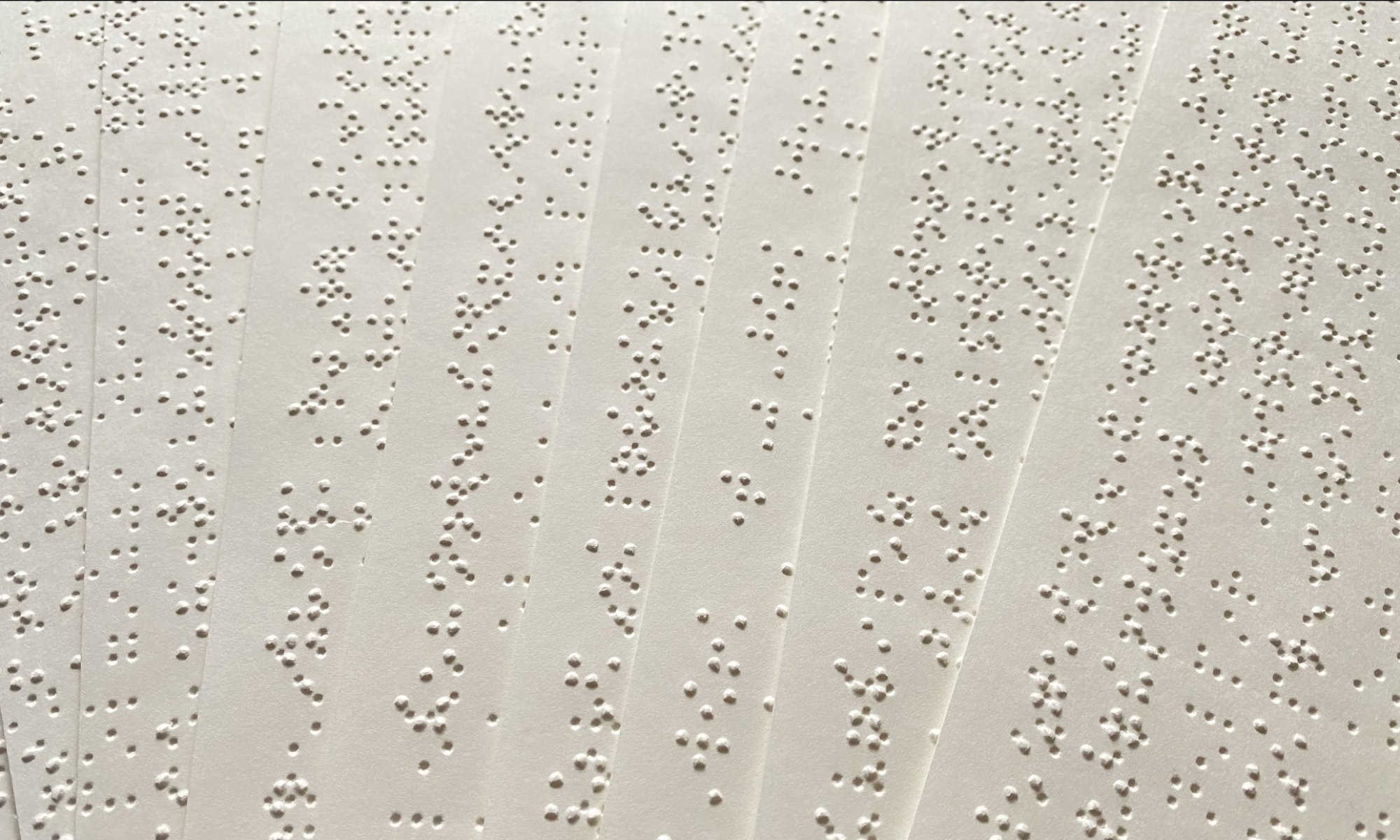

This a general idea of what the internals workings of our embosser. We will have a way to feed paper using a driven tread that keeps tension with an idler tread. The treads will be positioned such that the paper is touching the tips of the solenoids. We will be adding screws to the solenoids so just the tip will likely be fine. There will be another linear rail with another tread on the other side of the solenoid.

This is the x gantry. The x gantry will be driven by a lead screw because lead screws don’t stretch unlike pulley based systems.

Here is the y feed system in isolation.

We were advised against doing an X/Y coupled system.

Is your progress on schedule or behind?

We are right on time, we just need to order parts soon so we can begin testing this.

What deliverables do you hope to complete in the next week?

I want to order the parts for the x gantry system this week so I can begin manufacturing and making sure the parts fit together and reiterating as needed.