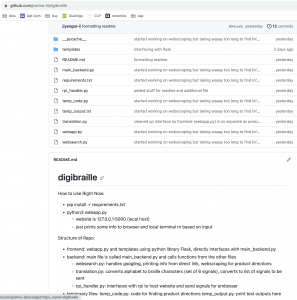

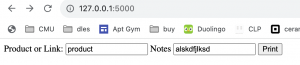

This week, I primarily focused on designing the solenoid embossing system and working with Becky to see how it would fit within the larger x/y gantry printing system. I also incorporated the user’s feedback into my current wireframe. (digibraille_wireframe_updated).

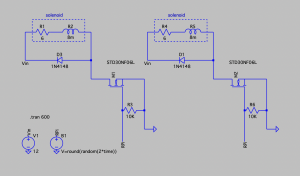

Before beginning the design of the solenoid system, I spent a lot of time consolidating my research from the previous week to select the best solenoid for our use. I decided on using a DC 12 V solenoid with a screw insert on the iron core. This solenoid will be the best for our use case because it provides enough force to emboss the paper (20 N) and will allow for us to screw in the braille pin-head for embossing. After I decided on the solenoid type I was going to use, I was able to begin thinking about designing the circuit and how to control the solenoid. This process involved employing my knowledge from my device sciences concentration, primarily 18-220 and 18-300 . The primary issues with using solenoids are the power consumption and controlling the switching of power on and off through the solenoid. The switching problem was an easy fix through the incorporation of a flyback diode in parallel with the solenoid. I am currently using an NMOS to control the circuit.

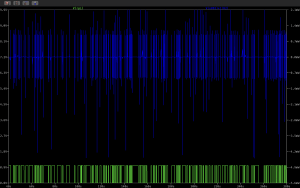

I tested this circuit in the LT SPICE simulator to make sure it was acting as desired, and would not exceed power requirements. Based on the available datasheet for the solenoid, I calculated its internal resistance and inductance and modeled it as a resistor and inductor in series for my simulation. I then ran simulations of this circuit on LT SPICE over a time window of 10 minutes (our predicted embossing time) to test the power consumption of the circuit. I fed in a randomized square wave to represent inputs from the RPi. Based on stimulations, this circuit appears to be stable and fits our needs. However, I may still make modifications as I continue to test.

I also began to prototype this circuit. I was able to test it using a waveform generator as displayed in the simulation and a DC power source. I hope to test it using the RPi in the coming week.

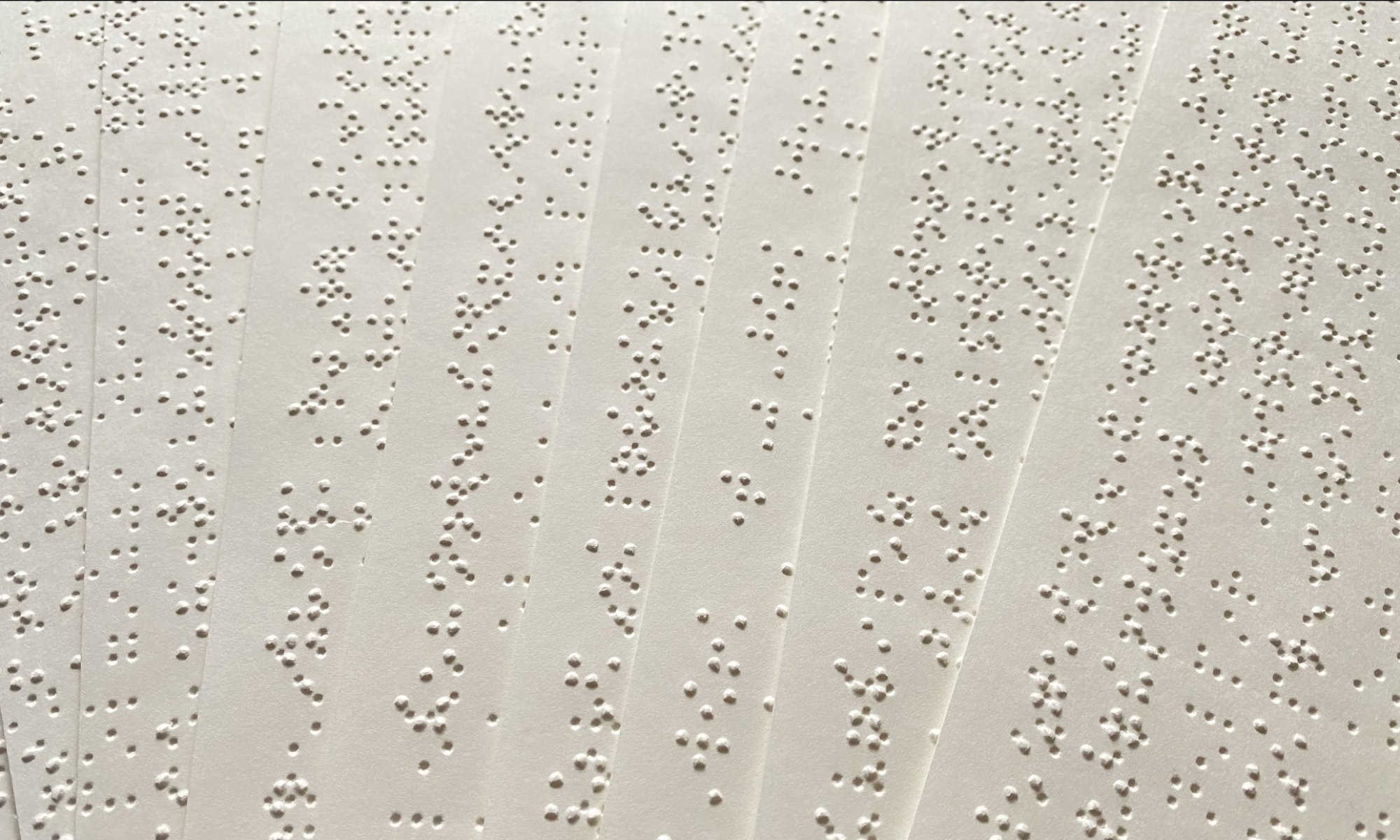

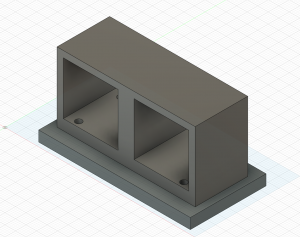

I also worked through the math for deciding how many solenoids to use and investigated the question of how the system will move (i.e. one cell at a time, one line at a time, one cell per solenoid). I calculated exact spacings between the solenoid and braille cells based on the American Society of Braille requirements and the size of the solenoid. Based on this, we decided the solenoids should move only in the x direction, embossing the braille line by line. I also calculated the time it would take for each number of solenoids to emboss based on the specific distances they need to be embossing within. Based on my results, I decided that two solenoids would be optimal, as the speed begins to plateau after two solenoids.

I also worked Becky this week on some of the design of the braille embossing system and x/y gantry. I designed an enclosure for the two solenoids in Fusion 360 that will fit into her x/y gantry design.

I also spent time working on the design proposal presentation — creating block diagrams, writing tests and requirements.

Is your progress on schedule or behind? If you are behind, what actions will be taken to catch up to the project schedule?

My progress is currently on schedule with the Gantt chart for the hardware components I have been assigned to. I am a bit behind schedule for the UI component of my role so I will devote the upcoming week to catch up on that. I aim to have the mock-up complete and some initial features implemented on the front end by the end of next week

What deliverables do you hope to complete in the next week?

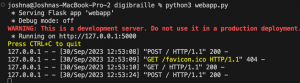

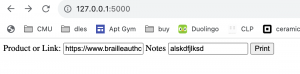

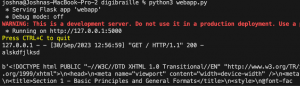

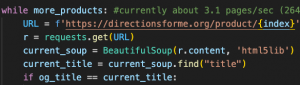

In the next week, I will continue to test the solenoid circuit with the RPi. I will complete the mock-up for the front-end of the web-app and begin implementing features. I will also work on the design proposal document.