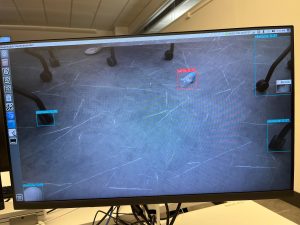

This week we focused on improving the bottle detection algorithm as well as building the structure of the intake mechanism on the iRobot. We were able to ssh into the Jetson, which has allowed us to do more field testing. For the bottle detection algorithm side, one main issue we’re facing is that our bottle detection has a very limited range of around 0.5 meters during testing, which means that bottles placed more than that distance away from the robot are not detected as bottles or as obstacles. We have been testing solutions to our robot’s myopia through incorporating tiling so that the yolov5 bottle detection model can run multiple rounds of inference on small sections of the image, which has provided significant success based on our algorithm without tiling. Another technique we have been working on is to increase the streaming resolution from the RealSense camera. However, the tradeoff for more accurate detection is a longer processing time, which is something we have to figure out how to balance. In addition to improving the range of vision, we have been working on merging the software sections together by running inference on a sampled frame while object tracking, and a rudimentary implementation of how we will track a bottle and determine how much to rotate the robot so that the bottle is within the center of its field of view.

For the intake mechanism, with almost all wood, metal, and lexan parts obtained and cut, we were able to construct the robot structure by mounting a base on the top bar of the iRobot and two arm planks on either side the bar. This allowed us to test attaching our intake mechanism to the ends of the arm planks and seeing if the iRobot would be able to move around with all of the weight. It was successful in moving, if not slowed down a little, but we will be trimming the length of the arm planks to the minimum distance needed to propel the bottles up the intake ramp. While the motor we have will have to be replaced with a stronger one with a higher RPM, the robot intake mechanism and its mounting on the iRobot is certainly coming together. We believe that we have made good progress in terms of the robot hardware and while not perfect, we are reasonably on schedule for that.

0 Comments