Final Video 12/12/2021

Team Status Update 12/4/21

Last week, we got the system running off of battery power. We’ve added JST-SM connectors to the batteries and the LED power connectors so that we can disconnect and debug more easily. The ON/OFF switch has been connected to the solder board, and the turn signal button has been connected as well. All of the hardware has been connected. The final mount will be printed next week so the physical component of the project will be finished after that is printed.

We’ve been having some problems with the communication between the STM and the Arduino. The GPIO from the STM works, but the Arduino code needs to handle the data more quickly for us to meet our timing requirements. Next week, we are going to test how the system handles and outputs the sensor data, rather than testing just subsystems.

Emily’s Status Update 12/4/21

This week, Albany and I had planned on doing some testing with the detection code and the sensors, but we ran into some problems with the STM again. We spent some time debugging the system overall. I discovered that some of my LED code wasn’t working. We fixed most of those problems. Since Jason has fixed the STM communication, I have to fix a problem with the interrupt code on the Arduino. Luckily I have a version of working code with slower updating, so I can compare the broken, faster code to the working, slower code to isolate the problem.

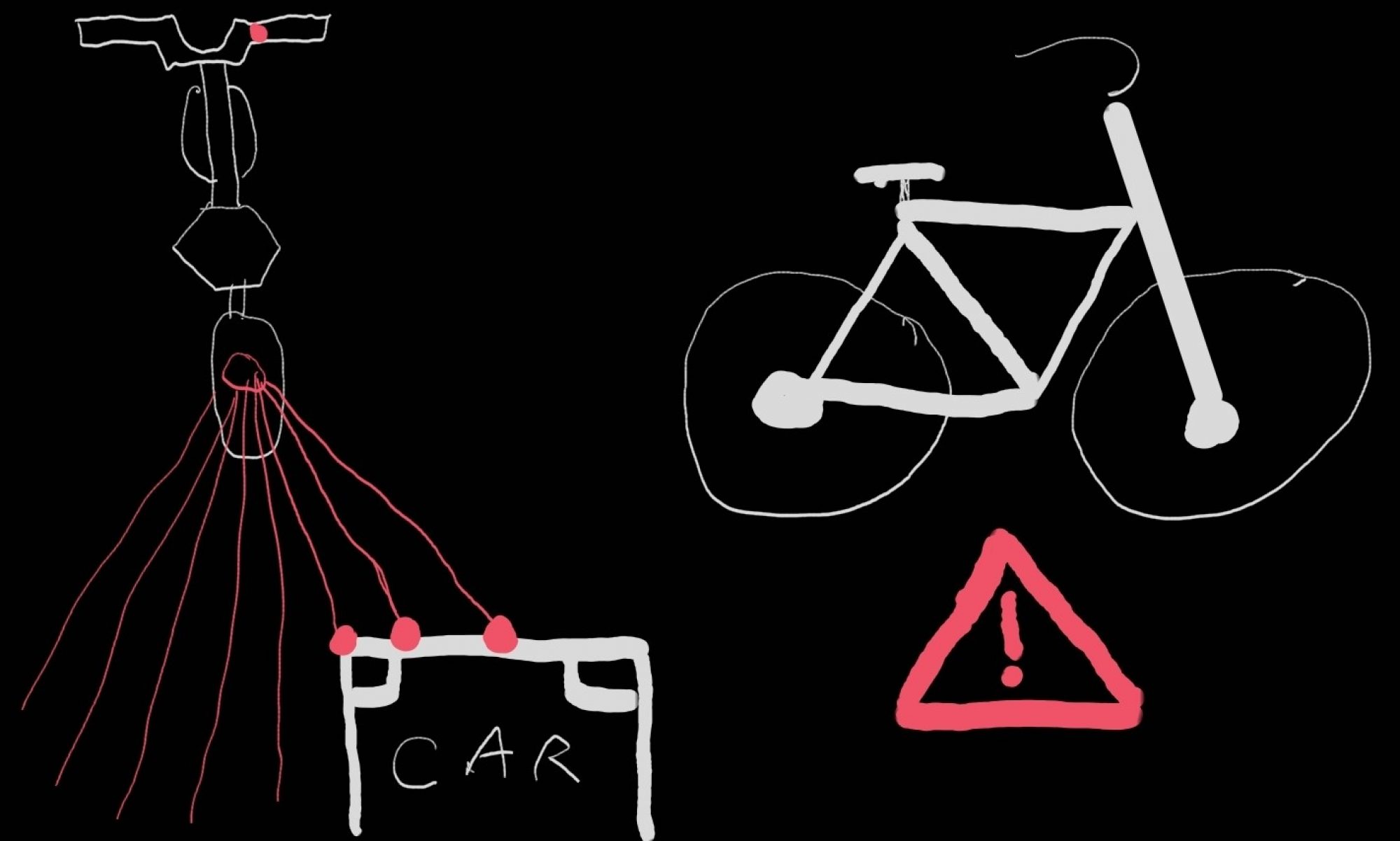

Today especially, everything decided to break. I was trying to refine the turn signals, but then one of them stopped working. Turns out the LED contacts had disconnected from the strip. I had also added a green LED on the handlebars to indicate that the system is on. Suddenly, that had stopped working as well. Again, by hooking up the working sets of LEDs, I determined that it was the contacts. I cut off the broken LED and Albany soldered the LEDs again. These two sets of LEDs were the only two that we hadn’t hot glued. Hopefully the hot glue prevents this in the future like it has for the other. Strain relief would’ve been good for the LEDs had we known that this was a problem The contacts for the LEDs are so small and the wires don’t have much area to contact.

I’ve also decided to CAD another mount. We had talked about not creating another mount because of time constraints, but we have room in the budget, and it will hopefully make it easier for us to do the final assembly. We don’t have space for the turn signals on the current mount, and we couldn’t find screws small enough to attach the sensors. I think printing is the best way to create an attachment for the sensors in this case.

My plan is to fix the Arduino code and send the CAD model for printing by Monday evening, that way we will have plenty of time to do the video and get some more testing in.

Emily’s Status Update

We’ve switched to using 5V batteries which we got in this week. I didn’t realize that the Arduino can run off of 5V through the 5V or through the USB input. This will also double our battery capacity. I tested them, they run at the required voltage. I’ve gotten the LEDs and the Arduino to run off of the battery power. I still have to test the STM, but it worked with the 12V, so this should be alright as well. Next up with power is to run the sensors off of the STM.

Jason and I tried to get various communications methods working between the STM and the Arduino. I’ll be helping with that more actively next week.

I’ve started modifying the CAD for the final version of the mount. We changed how the batteries are going to be positioned relative to the bike, so the mount overall will be smaller now and I won’t have to print it in two pieces. I’m also planning on printing circular clips to hold the turn and power switches on the bike.

I also got our light sensing to work on the Arduino. We use it to inform whether the tail lights need to be on, and I’m going to change it to set the overall brightness for the handlebar LEDs as well (so they aren’t so blindly bright at night).

I did some testing with Albany on the other sensor a couple days ago, and we are going to meet up on Sunday to do testing with the two sensors together on the mount. We are also going to use this to test the angular response of the sensors.

I emailed DFRobot about the sensors. We aren’t seeing the range that we expect and their documentation is very limited and unclear, so hopefully they will get back to us soon. We are continuing to move ahead, but it would be nice to get some kind of answer to what we are seeing.

Emily’s Status Update 11/13/21

Changed the LED code so that the different zones update concurrently. Before, each LED set would update in a serial fashion, but now they all update at once. Did some testing yesterday with Albany and my car and the sensors in an empty space so that we could get some data with less interference.

Been working on the power stuff. The Arduino and the STM can now run off the battery power. I just need to select the proper inductor size for the LEDs, and those will be ready to go as well. I’m thinking of switching the microwave sensors to run off of 5V rather than 8V because it seems unnecessary to have specifically 8V for it when it can run off of 4-8V. However, some of the data that we got from the sensors seem to suggest that the output range might be proportional to voltage and not power, so that would be a problem. I’m going to do some testing on Monday to make sure that this isn’t the case before switching over to only 5V converters.

Emily Clayton’s Status Report 11/6/2021

This week I initially re-soldered some of the LEDs, and then passed that off to Albany to finish off. Last week I had created the testing code for the LEDs, and this week I made and tested the functions that the Arduino will use when receiving data from the STM. Now Albany and I had to finalize what kind of inputs the Arduino will receive from the STM, then the LED portion will be done aside from hooking them onto the bike. I uploaded this code and the CAD files that were on my W drive into our git repository.

My plan for next week is to work on getting the battery power going for the whole system so we can start testing the entire thing in real world environments. I had to rework some of the capacitor/inductor selections for the 5V and 8V buck converters, since my values from last time were wrong. Even though we have the demos on Monday and Wednesday, I would still like to get everything for the battery power sorted by then, so by next week we can start testing with the batteries.

Team Status Update 10/30/2021

This week we received all of our parts in the mail, so we are moving forward with testing and working on integrating as much as we can. We have been working in getting coherent data from the sensor and using that to inform the filter for the data. Since we have the mount, next week we will be able start testing with data from both sensors in the same arrangement that we will likely use for the final. The survey for the LED communication is almost done, so by Monday we will be able to distribute the survey and make a final decision on how we will display our outputs on the system. We finally got the STM in the mail, so we are starting initial programming to integrate that into the system. All in all, having all of the components is allowing us to move forward quickly with the system.

Emily’s Status Update 10/30/2021

This week I did some more work on the mount. I hadn’t accounted for the cables that hang out of the back/bottom of the microwave sensors, so I used a rotary tool to take some of the plastic away. Since the part that the microwave sensors are secured to is somewhat suspended from the rest of the mount, it is unlikely to cause any problems.

This week I started coding for the LEDs. We will be testing the patterns for communication next week, so I coded the various patterns that we are thinking of using and took video of them. Then I paired those pictures and videos to questions about their effectiveness. I still have to attach photos of the situations that they are meant to communicate for certain questions. The initial questions in the user survey are meant to remove as much of our bias from the view of the participants as possible, while the later questions are targeted as informed feedback.

Emily’s Status Report 10/23/21

Since we’ve gotten in the sensors, I designed the bike mount for the system so we can start gathering data for the filter and do some testing. Using Jason’s bike as reference, the mount screws into the back mounting points and has zip tie points to provide more stability and to accommodate differently sized racks. It has screw holes to mount the STM, the arduino, solder board, and the sensors, and bracketing and zip tie points to house the batteries.

Last week, I worked on the hardware sections and the budget for the design document.