Members

- Kwabena Agyeman - kwa@

- Matthew Bauch - mbauch@

- Nico Paris - nparis@ http://hacktastico.com/)

- Robbie Wedler - rwedler@ (http://robbiewedler.com)

Note: all email addresses are @andrew.cmu.edu

Concept

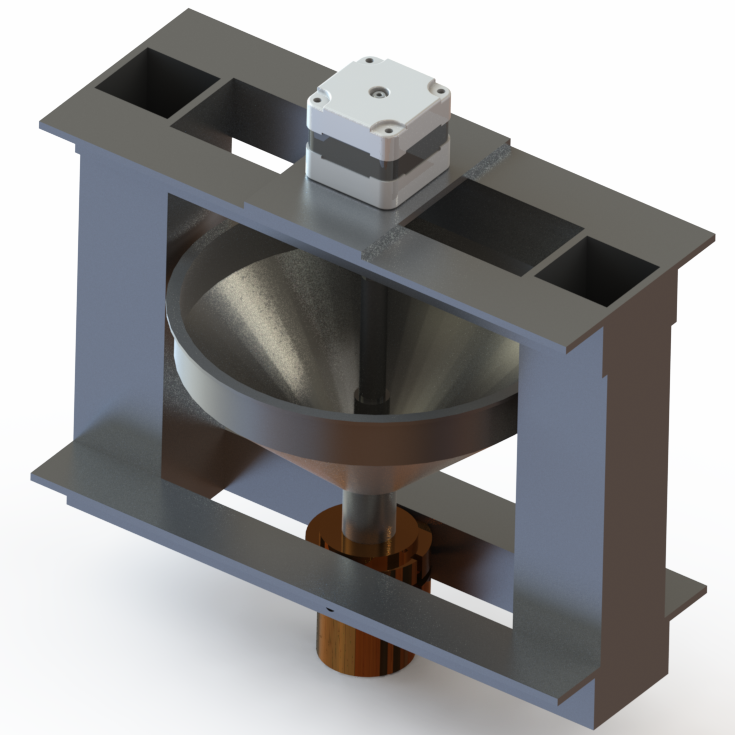

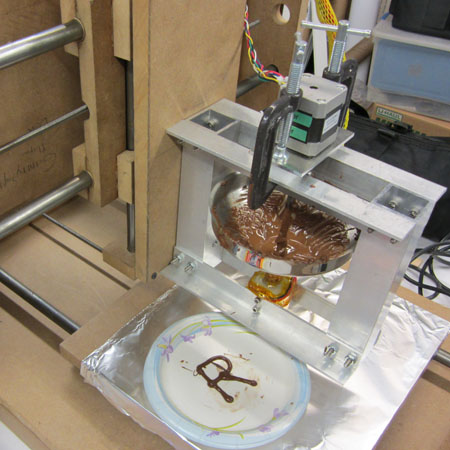

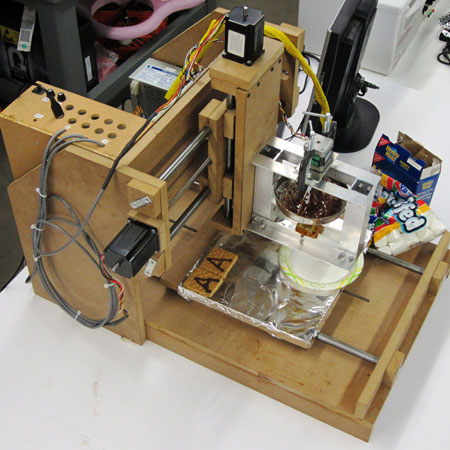

The WonkaBot 3D Chocolate Printer is a 3-axis CNC machine with a heated chocolate extruder. WonkaBot allows you to print edible chocolate treats from any CAD model.

Motivation

As 3D printing becomes a more pervasive technology, the next logical step is to print edible items. Chocolate is a natural choice as it melts and hardens easily and tastes great.

Competitors

There are no commercially availible 3D printers that produce hard chocolate treats.

The Imagine 3D printer by Essential Dynamics is a similar product, but is different in its method of extrusion. Based on a syringe system, the Imagine printer can only extrude liquid chocolate as it has no heating element. Additionally, the Imagine printer is prohibitively expensive at about $3000

Another competitor in the realm of food printing is the Cornucopia by MIT's Media Lab. The largest difference between WonkaBot and Cornucopia is that at the moment, Cornucopia is only a concept. Additionally, the Cornucopia is more of a food dispenser than a printer as it utilizes a servo-actuated hopper system of food deployment with no provisions for any sort of gantry or other 3D positioning system.

Technical Specifications

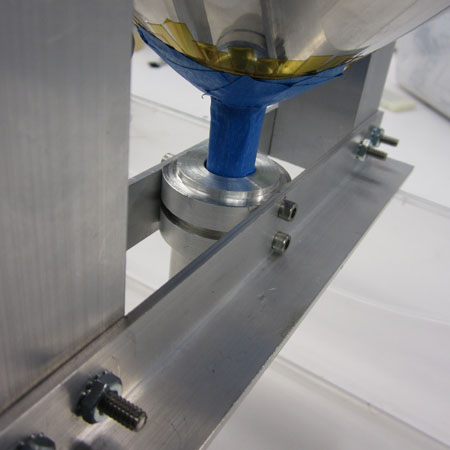

Extruder - We plan to use Nichrome wire wrapped around the metal chocolate basin to act as an electrically controlled heating element. We will use an Archimedes screw to drive the melting chocolate through a small nozzle to create the thin chocolate filament used for printing.

Platform - The platform will be made of a metal sheet attached to a peltier unit which will act as a cooling agent, solidifying the hot chocolate.

CAD to GCODE software - We plan to use the open-source ReplicatorG software to perform the necessary conversion of CAD to GCODE

Gantry system - Our current model for a gantry system consists of donated 80/20 aluminum extrusion with attached linear slides. The axes will be actuated by stepper motors which deliver a high level of feedback and control.

Electronics - We will base our electronic control system after the MakerBot MotherBoard (expansion for Arduino MEGA board) which provides control for multiple stepper motors and sensors as well as an interface with the computer CAD program.

Requirements

Upon completion, the WonkaBot will be able to quickly print edible chocolate treats (that taste good) from models supplied via availible CAD software (Inventor, Solidworks, etc.)

Risks

Chocolate extrusion is an area where there has been little prior research. One of the largest risks we face is designing and creating a chocolate extruder. To mitigate this risk, we intend to look to existing plastic and hot glue extruders for inspiration.

Another risk we face is the fact that accurate gantry systems are hard and expensive to manufacture. We plan to mitigate this risk by looking at inexpensive off-the-shelf linear bearing systems (drawer slides) as well as more pre-built, industrial grade systems (80/20).

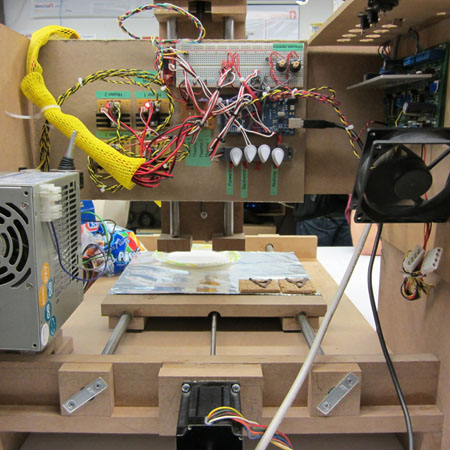

Pictures

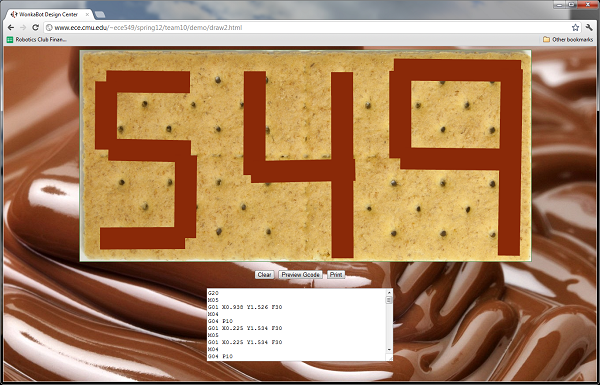

Web interface

The web interface is a graham cracker that can be drawn upon with mouse clicks (with the print button currently disabled)

Demo Day Pics

Media

February 8, 2012 - Presentation 1 (pdf)

Special Thanks

We would like to

thank the CMU Robotics Club for providing a great workspace.

Andrew Burks (http://andrewburks.com), for his help in modeling and machining critical parts of the extruder.

Harrison Rose, for letting us borrow his 3-axis cnc.