- This week, I mainly worked on writing code to transmit data between 2 Arduinos. This involved using 2 wireless transceivers to test whether commands could be sent back and forth between them. I worked on this with Ryan. Together, we tested whether a command could be sent from one Arduino to the other to control an LED. Once this worked, we tested if we could send commands to control the motors connected to the Arduino on the coat rack. After creating the data structures and specifying the communication between the two sides, I helped in testing the integrating between the facial recognition system and the components on the rack, with Ryan and Surafel. This involved transmitting data from our python program and being able to rotate our motors when someone attempted to check-in and check-out. We have found some issues when testing this, and plan to continue our integration efforts and fix any software problems that arise upon further testing.

- My progress is slightly behind. Although a majority of the work for the hardware components and associated code has be finalized, our team still plans on making further changes, like replacing our current motors. According to the scheduling, we are solely supposed to be integrating the different components of our systems, but with this change, we need to work on integration while we make the necessary motor changes to ensure that we can satisfy our use case requirements. In addition to this, with integration, there is a possibility that we may realize that system components that seemed to work on their own, may not work together, which may require additional work to fix.

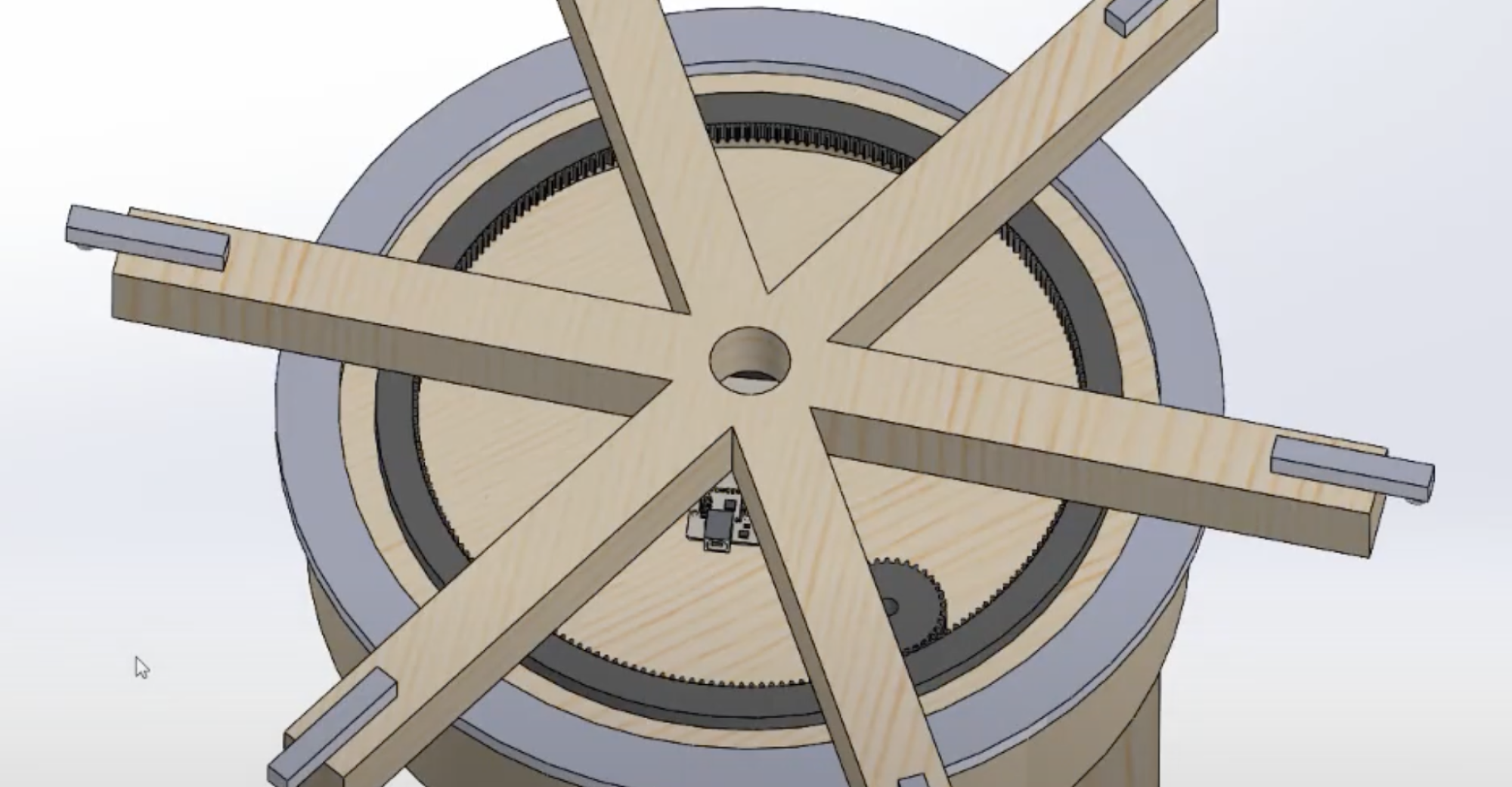

- For next week, I will continue working on integrating the facial recognition system with the hardware system. Although we have been able to successfully transmit data from our python program to the Arduino Mega on the rack using wireless transceiver, I want to ensure that users can successfully check-in and check-out. In addition to this, I want to ensure that the motor can correctly turn to the position specified by a user’s item position on the stand. In addition to working on these software aspects for the project, I want to complete the hardware aspect by substituting the Nema 17 motor with the Nema 34 motor, which is expected to arrive next week. I would like to test that the holding torque for the motor actually satisfies our use case requirement, sustaining rotation with up to 20 lbs on each of the 6 hooks on the rack.

Carnegie Mellon ECE Capstone, Spring 2024 | Doreen Valmyr, Ryan Lin, Surafel Tsadik