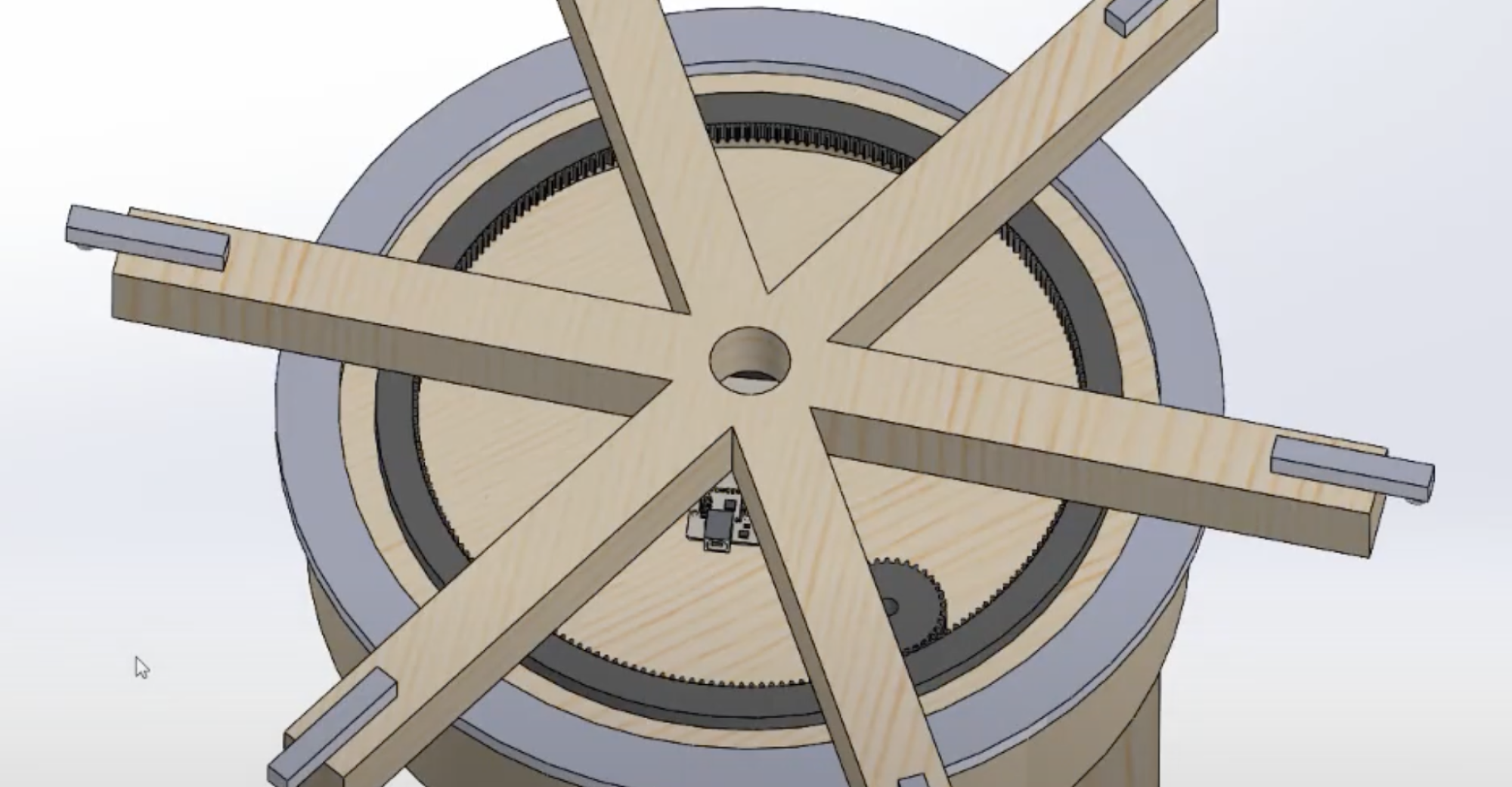

- This week I worked with my team member on the hardware component of the project. This involved painting the rack and creating cutouts for electronic components. We determined the placement of the load cells, slip ring, and power cord on the rack. To ensure that these components could be placed, we had to make more cutouts on the stand. In addition to this, we assembled the bottom portion of the stand by attaching L brackets to the base and legs of the stands. Furthermore, I helped with testing the load cells. Although we had tested them in previous weeks, we wanted to see if the power, ground, and clocks line could be combined for the load cells, which required further wiring and testing.

- According to our Gantt Chart, we are still on schedule because we anticipated the current setbacks. Our schedule states that we should be assembling our rack and adding the electronic components, which is what we are currently working on. However, we need to ensure that we have less setbacks with the motor, by quickly testing our new motor driver, in case we need to make additional plans to ensure that we can accomplish our requirements.

- For next week, I will help test our motor driver controller and wireless transceiver. In addition to this, I will help further assemble the rack, so that it is at a more completed state. Refer to the team status report for updated media/images.

Carnegie Mellon ECE Capstone, Spring 2024 | Doreen Valmyr, Ryan Lin, Surafel Tsadik