Risks:

The mechanical stability and reliability of the scissor lift are crucial for the accuracy and completeness of our LiDAR scans. A failure or instability in the scissor lift mechanism could result in incomplete or inaccurate data collection, impacting the quality of the generated 3D models. In the event of significant issues with the scissor lift, we have prepared designs for a shorter, more stable version.

Utilizing a camera for furniture classification introduces the complexity of accurately associating the identified items with their specific locations within the LiDAR-generated 3D scan. Relying solely on LiDAR data for furniture classification may be limited by the resolution and detail of the point clouds generated by the RPLiDAR.

Design Changes:

A small design change was made to the scissor lift. We have opted to use longer scissor arms and slightly larger bearings, which would mean fewer arms overall, and the larger bearings are more readily available. Neither the longer scissor arms nor the bearings will incur a significant cost as we are still within our budget.

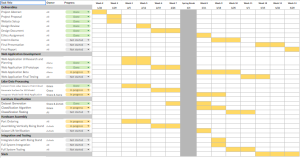

Schedule Changes and Updates:

Some changes were made to the schedule to the Web Application Development section. The 3D Model section was removed as we felt the LiDAR Integration section was covering most of the work with the 3D modeling. The Web App Backend section was also replaced with Web Application Beta because the web app as a whole is being worked on rather than just the backend due to how interconnected everything is and that felt like a better description. More time was given to the Beta section to reflect how it’s just overall development now instead of just one part. The Web App Testing section was also pushed back to reflect this.

Developments:

Overall, just making progress on getting all the parts of out project to work together.