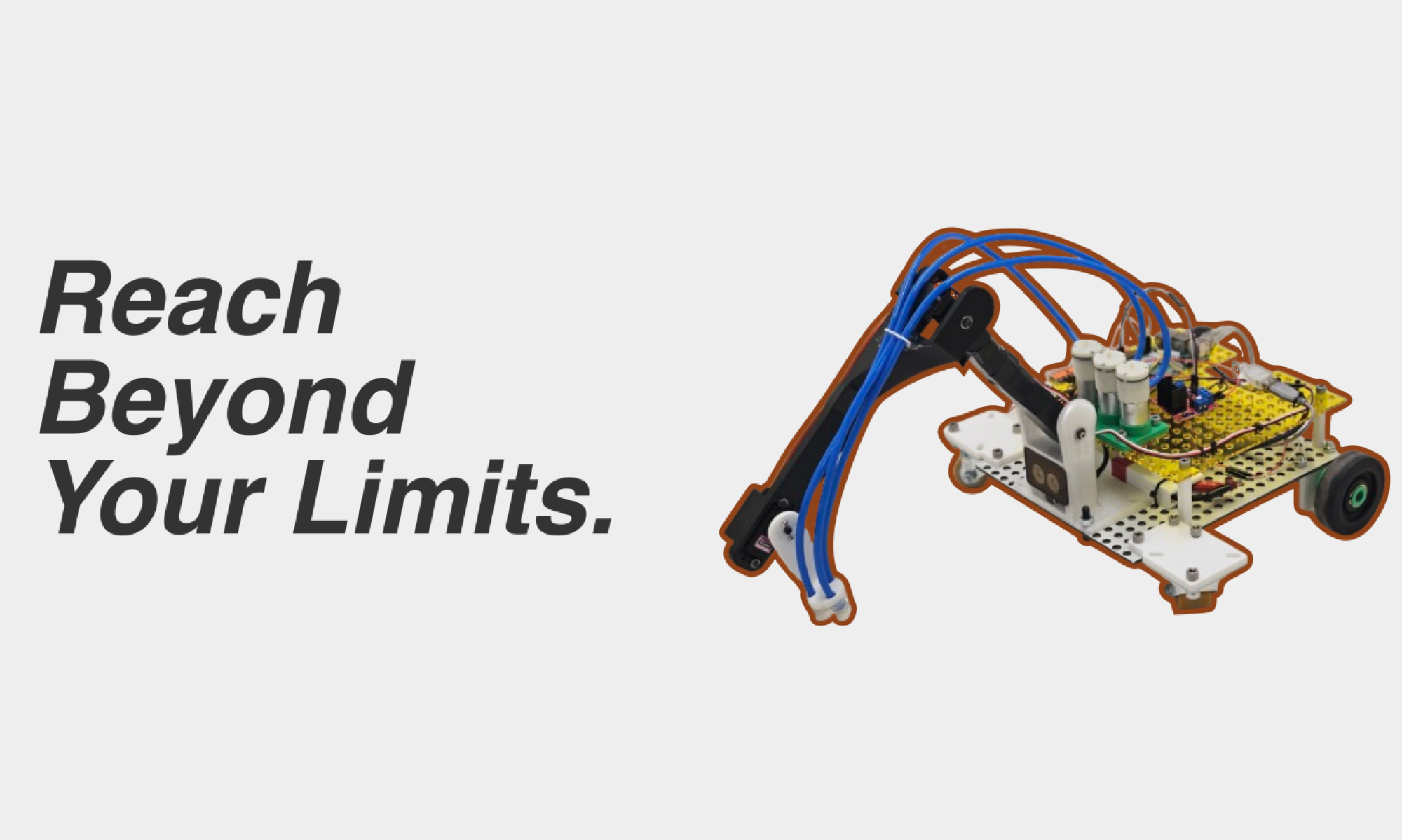

This week, I focused quite a lot on designing the suction system for our robot and finalizing the robot arm. On Monday, I showed Prof Mukherjee a conceptual version of our robot arm, but upon further re-evaluation, I decided that it would be better if I designed it in a much more modular fashion. I designed modules for our torque servos and the non-torque servo (that controls the suction cups) in a way that could interface well with the previous design, so that not much change needed to be made. Here is the final design of the end effector movement Robot Arm:

The design of the arm, though it looks quite complicated, did not take nearly as much time as the conceptualization of the suction mechanism. On Monday, I showed Prof Mukherjee the mold that I had spent time designing to create the requisite suction for our project. When I tried to use some silicone resin to actually fill in the mold, I made a mess, and once it actually dried, nothing came out of the mold. I either hadn’t designed it correctly, or my process for transferring the resin was incorrect. Either way, when I came back to it on Tuesday to try and get the mold, I realized that the process of iteration for this would be unnecessary and tedious. The solution? Money. I scoped out a relatively cheap silicon bellows suction cup that would allow us to conform to the shape of the object we want to pick up, and I found one on Amazon that would work.

Pictured above are some of the pressure calculations. With this in mind, though the syringe could definitely generate enough pressure for the task at hand, I realized that we may want to use multiple suction cups. To generate enough pressure, I need a bigger syringe, and with a limited amount of real-estate on our Rover, I needed a better solution, so I found some DC air pumps that will do the job well.

Some more time was also spent on trying to figure out how to interface with the silicone. The cups I found interface with an M5 thread, and the DC pump can connect to 4 mm tubing. I found an interface between tubing and threads that fit the aforementioned numbers, and we’ll buy those on Monday!

My progress is a bit behind in my eyes, but we have a large overall goal to finish assembly by March, and I still think that is possible. From here, I will spend time to 3D print parts and ensure that we can get our hands on our physical material as soon as possible.

Varun’s Status Report for 2/10/24

This week, I focused on a few things-

- Finalizing the Pickup mechanism– As we mentioned in the presentation, we had a plan to experiment with ER fluid. ER fluid, also known as Electrorheological fluid, is a type of fluid that, when subjected to an electric field, solidifies, to the point that if it were around an object, it could theoretically pick it up. The below image demonstrates this in action.

source

source

I set up a testing apparatus using a power supply, and a mixture of corn starch and silicone oil. When I tested these together, the fluid unfortunately did not solidify. I later found out that this was because I inserted leads into the fluid, and not an actual pair of plates to simulate an electric field, so there would be no way for it to work. However, upon further thought, I realized that in either case, the ER fluid gripper would not work, as the part would obstruct the electric field going through the fluid, and if the field was too strong, it may end up eating through our battery life. Luckily, I found this YouTube video which explained the process of using a syringe in order to create suction around an object using a silicone mold and a servo to actuate the syringe. The design mentioned in the video, with a miniature servo and a small syringe, could hold 300 grams. As our goal is to hold 700 grams, I conceptualized and am currently designing the suction mechanism to hold 700 grams, with a bigger servo that (according to physics first principles) should generate more upward force on the object. With this in mind, the servo itself should be of much higher torque, to physically hold the syringe in place as the suction grips the object. - Finalizing Electronics– Based on my prior experience with Combat Robotics, I began the process of designing the guts of the Rover before beginning the actual design of the structures around it. I began by doing some simple Torque Calculations, to pick the servo that would end up being at each point of the robot arm. Based on the fact that our goal is to pick up a 700 gram object at a distance of 20-30 cm away, I elected to use a 75 kg/cm servo in order to hold onto the object. Make no mistake, this is definitely overkill, but I wanted to make sure that we don’t run into an issue in the future. Based on budget constraints, I will update the power of the servo (if need be). With that in mind, I am currently finishing up the design of the Robot Arm, and we will post full pictures of the Rover design by next week (and in this post as well)!

- Learning PCB Design– Surprisingly enough, in my 3 years here, I have never needed to design a PCB, and as such did not have a great idea as to how I would go about designing one. I took a class at the RoboClub on how to design a PCB in KiCad, and below is the 3D render of how it will come out!

We’ll be populating them in the next few weeks, but that’s a separate process. Either way, this will be very useful when we are designing the on-Rover PCB.

I am on schedule, but am definitely cutting it close. I have finished a lot of the introductory knowledge that I need to have for this project, and can therefore be much closer to the timeline in the future. My next week goals are to have the kinematic scheme fully-fleshed out with Hayden and the communication protocol flushed out with Nathan, and to order parts for our project to begin work.

Nathan’s Status Report for 2/10/24

At the beginning of this week, the majority of my work went into preparing the proposal presentation slides and meeting with Hayden to finalize the presentation and offer feedback. Personally, I made the use case and problem description slides as well as created the Gantt chart and inputted the tasks we need to achieve on Asana, our technology of choice.

After the presentation and after reviewing our TA feedback, I started to research the required technologies for my end – the depth camera or a LiDAR camera. Upon discussing with the team, we decided to acquire one of each since the ECE inventory already has a LiDAR camera that we can access without cutting into our budget. I filled out a request with ECE receiving and I hope to receive the camera sometime next week so I can start playing with it. In the meantime, I am researching how to interface with the camera and any needed technologies that are required for it to function properly. Since my area of focus is mostly on software, I am also starting to research how to translate what the camera sees and the information it gathers to the kinematic motion of the arm. This is still very much a work in progress.

Currently, my progress is on schedule since I am waiting for the technologies to arrive before I can actually start digging into experimentation and research.

In the next week, I hope to be able to receive the materials and play around with them. I hope to be able to write extremely basic code for the camera and RPi and perform basic setup tasks for the two so we can establish a good basis for the coming weeks as further experimentation occurs.

Hayden’s Status Report for 2/10/24

This week I spent most of Sunday fine tuning the presentation and practicing for the presentation. I spent Monday morning prior to presenting reviewing our design and preparing for the presentation questions. After the presentation, I spent the rest of the week researching drive trains and CADing different designs in Autodesk Fusion 360. After researching and discussing we settled on a tank-drive system rather than a Rocker-Bogie suspension drive system. I drew both of these up in CAD just incase we want to implement the Rocker-Bogie at a later date. I also designed the modular baseplate to be able to mount our different robotic modules to the base of the robot. We decided that a peg-board type system would be best for experimentation and development.

In addition to working on the physical CAD I also touched up my PCB skills and drew up the basic PCB layout for the user controller. I found a button that could perform in the manner we wanted and that was similar to a computer key. I am currently researching methods to convert an analog high signal into USB protocol to then communicate with the Raspberry Pi on the user side.

My progress is right on schedule but I need to complete the CAD for the robot body this week. I will need to wait for Varun’s robotic arm design to properly scale parts to make sure the robot is stable. I will have the PCB completed on the user side by the end of this next week and I will have the entirety of the drive train and body of the robot mapped out. I also need to continue researching electronic speed controllers (ESCs) and other electronic components that I want to incorporate into our design.