This week, I focused on a few things-

- Finalizing the Pickup mechanism– As we mentioned in the presentation, we had a plan to experiment with ER fluid. ER fluid, also known as Electrorheological fluid, is a type of fluid that, when subjected to an electric field, solidifies, to the point that if it were around an object, it could theoretically pick it up. The below image demonstrates this in action.

source

source

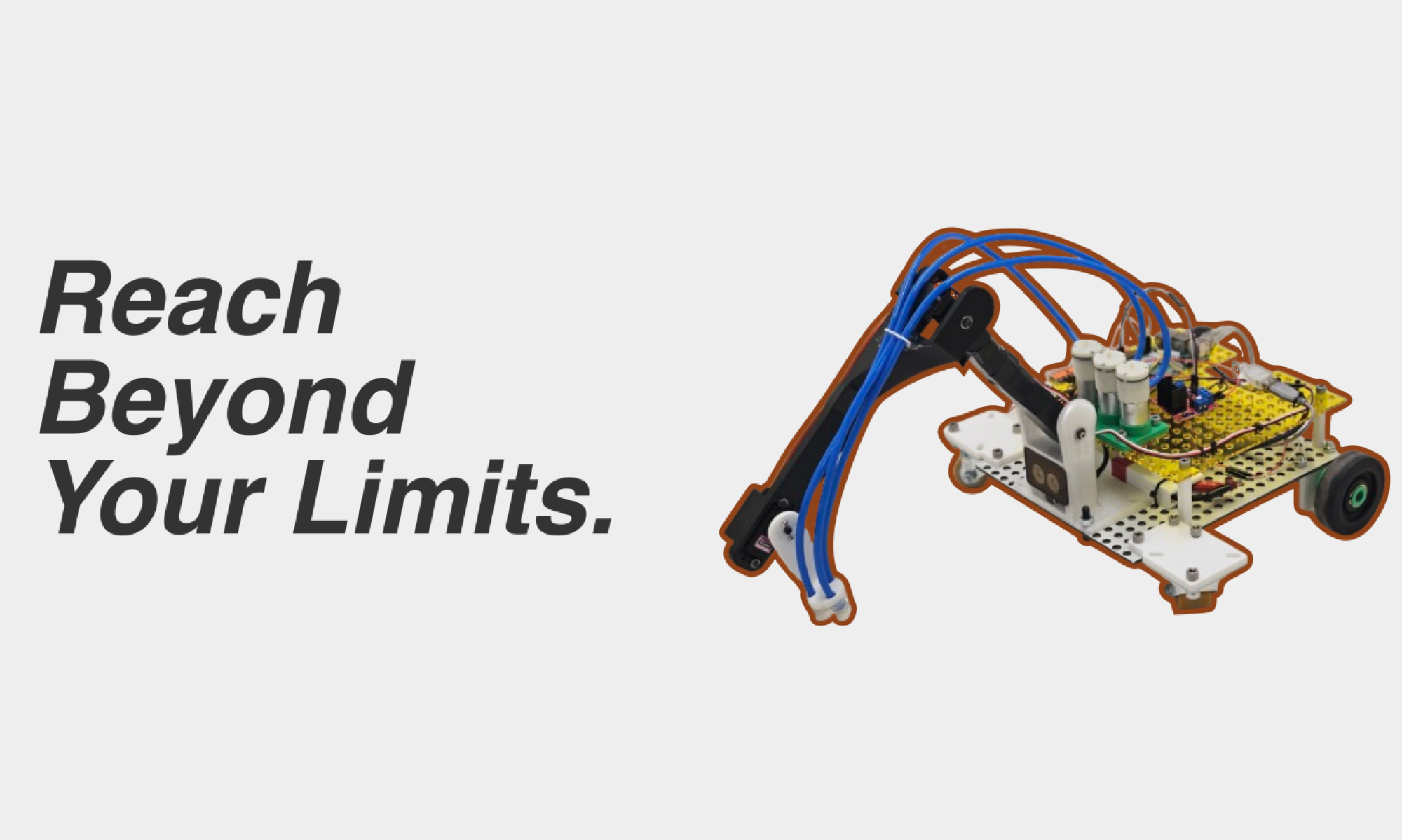

I set up a testing apparatus using a power supply, and a mixture of corn starch and silicone oil. When I tested these together, the fluid unfortunately did not solidify. I later found out that this was because I inserted leads into the fluid, and not an actual pair of plates to simulate an electric field, so there would be no way for it to work. However, upon further thought, I realized that in either case, the ER fluid gripper would not work, as the part would obstruct the electric field going through the fluid, and if the field was too strong, it may end up eating through our battery life. Luckily, I found this YouTube video which explained the process of using a syringe in order to create suction around an object using a silicone mold and a servo to actuate the syringe. The design mentioned in the video, with a miniature servo and a small syringe, could hold 300 grams. As our goal is to hold 700 grams, I conceptualized and am currently designing the suction mechanism to hold 700 grams, with a bigger servo that (according to physics first principles) should generate more upward force on the object. With this in mind, the servo itself should be of much higher torque, to physically hold the syringe in place as the suction grips the object. - Finalizing Electronics– Based on my prior experience with Combat Robotics, I began the process of designing the guts of the Rover before beginning the actual design of the structures around it. I began by doing some simple Torque Calculations, to pick the servo that would end up being at each point of the robot arm. Based on the fact that our goal is to pick up a 700 gram object at a distance of 20-30 cm away, I elected to use a 75 kg/cm servo in order to hold onto the object. Make no mistake, this is definitely overkill, but I wanted to make sure that we don’t run into an issue in the future. Based on budget constraints, I will update the power of the servo (if need be). With that in mind, I am currently finishing up the design of the Robot Arm, and we will post full pictures of the Rover design by next week (and in this post as well)!

- Learning PCB Design– Surprisingly enough, in my 3 years here, I have never needed to design a PCB, and as such did not have a great idea as to how I would go about designing one. I took a class at the RoboClub on how to design a PCB in KiCad, and below is the 3D render of how it will come out!

We’ll be populating them in the next few weeks, but that’s a separate process. Either way, this will be very useful when we are designing the on-Rover PCB.

I am on schedule, but am definitely cutting it close. I have finished a lot of the introductory knowledge that I need to have for this project, and can therefore be much closer to the timeline in the future. My next week goals are to have the kinematic scheme fully-fleshed out with Hayden and the communication protocol flushed out with Nathan, and to order parts for our project to begin work.