This week’s accomplishments

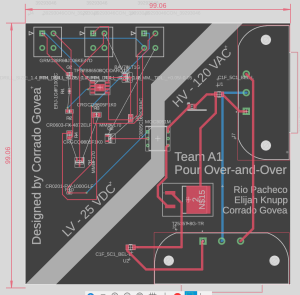

- This week I made some major modifications to the power management PCB.

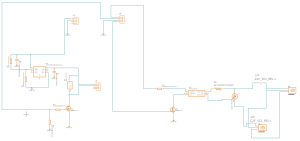

- Initially, I had designed a special circuit to do zero-crossing detection for the triac. This would require having a separate Arduino code to handle the zero-crossing detection and actuate the triac gate.

- After some research, I found a newer version of the triac driver that I had selected, which has zero-crossing detection incorporated. This allowed me to remove the entire detection circuit.

- I also re-did the layout with much thicker traces for the HV side of the board, and changed some components that were not rated for 120VAC.

- Lastly, I compressed the layout in size to reduce the PCB cost from >$60 to just $2 for qty 5.

- Initially, I had designed a special circuit to do zero-crossing detection for the triac. This would require having a separate Arduino code to handle the zero-crossing detection and actuate the triac gate.

- I also submitted the purchase forms for both the PCB and the components (smd for pcb and through-hole for prototyping).

Next Week’s Deliverables

- Write Arduino code to control the kettle and pump.

- Test prototype circuit when components arrive.

- Reflow one board and test.

Status Report: On schedule