Team Status Report for Apr 27, 2024

- What are the most significant risks that could jeopardize the success of the

project? How are these risks being managed? What contingency plans are ready?

There are two significant risks: 1. The jamming of the slider is still an issue, this prevents the motor from identifying the exact position it is in at any given moment. We have already identified the issue, and although mitigation efforts were made (referring to Ziyu’s status report), this problem is still not solved 100%. 2. The actuation speed of the motor is still way behind our initial design requirement. Samay is working on improving the motor driver’s code to get smoother actuation, but this proved to be a difficult process. As of now, no better solutions can be given besides pouring more hours into it before the final demo.

- Were any changes made to the existing design of the system?

We made our final changes last week, and they are documented in last weekly report and this week’s final presentation. No further adjastaments were made this week.

- Provide an updated schedule if changes have occurred.

No schedule changes.

- List all unit tests and overall system test carried out for experimentation of the system. List any findings and design changes made from your analysis of test results and other data obtained from the experimentation.

Software Unit testing:

- Web App user-testing:

- 1st iteration feedback: low usability due to txt.file support only

- 2nd iteration feedback after change: 8.75/10 for usability and user-friendliness

- Braille algorithm testing:

- 100% accuracy on 100 randomly generated words (Grade 1 + Grade 2)

Due to the braille translation algorithm successfully fulfilling the user-case requirement right off the first iteration of the test, we did not have to change our backend software design. However, after the first iteration of user-testing on our web app, we got a low score of 6.5/10 on usability due to the fact that our website only accepted .txt files users and did not deal with the errors that were generated from corrupted txt files. Therefore, we fundamentally changed our web app design to take in direct user-inputs from the keyboard through a clean prompt window generated from our website and decided to display every word typed and successfully added to our braille pad database.

Hardware:

- Unit: Average time per cell actuation: Uploaded final Arduino code, ran Python translation script for >15 characters, and recorded total time taken. Results: 0.73-0.82sThis finding has led me to try and optimize speed as we are aiming for 0.5s per cell. I have to try different motor operating modes and continue experimenting. We will also try to reduce jamming of pins by making them thicker, since the pins “lagging” causes the slider to click with friction and thus slow down.

- System: Homing precision and reliability: Ran testing of the slider initiation sequence upon first starting our whole system. Expected a quick back-and-forth until the motor “found” home position to then start accurate positioning of braille cells. Results: failed to get repeated trial successes. The motor often failed to detect a jam and other times just did not respond. This must be immediately investigated and start fallback plan of a physical limit switch.

Ziyu Li’s Status Report for April 27th, 2024

- What did you personally accomplish this week on the project

More testing is done on the braille cell, and I have done some detailed optimization on the CAD models. One persistent problem we were facing is that if we 3D print the body of the pin to be the exact same width as the pin holder, they will induce a lot of friction, but if we were to sand the pin down a bit so that it can slide smoothly, the pin will rotate slightly when the slider is pushing it up and down, resulting in a lot of jamming. A lot of experiments was conducted as attempts to mitigate this, and so far the solution with the best result is to include a slightly wider strip at the upper end of the pin to reduce rotation, while only adding a small amount of extra friction. We also experimented with using graphite as a solid lubricant, but oddly this does not improve the result observably. - Is your progress on schedule or behind?

Our progress is on schedule to be demoed at the final showcase, our project works as of now, but the actuation speed is way behind our design requirement. It will be tough to optimize it to meet our initial goal due to fabrication precision and limited testing time. - What deliverables do you hope to complete in the next week?

Beside optimizing the mechanical side of things, I also plan to “beautify” the project a bit more by 3D printing the product using black, white, and orange color palette, so that the audience can get a getter sense of how our actuator is working. I also plan to make some visual elements for our posters and final report (beside writing them) to better showcase our mechanism, like a exploded view of the assembly.

Ziyu Li’s Status Report for April 20th, 2024

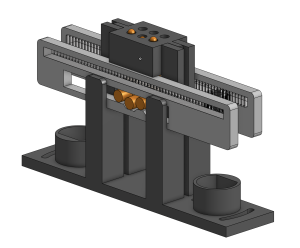

For the past two week, I made substantial revision to the CAD design of our actuator. The motor no is placed in the middle of the two sliders, which drastically reduces the footprint of the device. The gear and rack configuration is relocated to the side of the slider, instead of up of down.

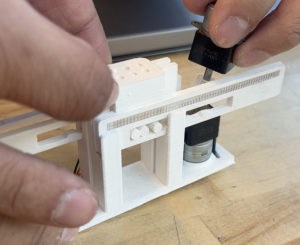

I also 3D printed and tested the integration of the system, as well as some preliminary test on the motor integration, which is shown here

We are on track to complete the project on time. Next we will perforce more verification test, and optimize for motor actuation speed and torque.

- As you’ve designed, implemented and debugged your project, what new tools or new knowledge did you find it necessary to learn to be able to accomplish these tasks? What learning strategies did you use to acquire this new knowledge?

I am mostly in charge of designing the CAD model for our actuators, and fabricating the product using 3D printing and laser cutting. I found myself having to engage with every detail of the softwares tools I used before more, especially because we are trying to build something that is both small and precise. I have to rapidly prototype with different 3D printing parameters to find the one the give the best result. I also had to relearn gear design to make sure the actuation is fast and smooth.

Ziyu Li’s Status Report for April 6th, 2024

What did you personally accomplish this week on the project?

Two major things is done this week: 1. using hand to hold the motor to actuate the slider from last week, I identified that the best place to mount the motor is actually above the slider, not underneath like I expected. This is likely due to when motor is underneath, it also provides an upward force to the slider, causing it to jam with the pins more easily. Mounting the motor on the top can eliminate this non-horizontal force since the support for the slider is underneath. 2. Given this, I redesigned the whole actuator by allocating more space between the cover and the slider, I also designed and tested the motor mount, which at the moment does not work perfectly since their are some tolerance differences from the 3D printer, but I am confident that I can solve this tomorrow.

Is your progress on schedule or behind?

If compared to the original plan, which is to build 10x of these actuators and having with coordinate with each other, I am definitely behind. However, since the interim demo, we acknowledged that having one braille cell work perfectly is more important than building a ~70% working whole, and given the difficulties in this process is much bigger than we expected, we have scale down to that. And in this regard we are on schedule.

What deliverables do you hope to complete in the next week?

A single braille cell working, shifting to different braille patterns.

Test that I am planning to run

After I get the braille cell working next week, I’ll focus on three major tests to make sure our product is meeting the original design requirement:

- activation speed: the slider should be able to move from one end to the other under 200ms.

- Jam frequency: the slider should not be jam in between at least 15 actuations (switching from one position to the next under the speed outlined in 1)

- Jam recovery: the actuator should automatically detect jam situation and recover from it using the back-and-forth motion in under 500ms.

Team Status Report for March 30st, 2024

What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

The most significant risk is on the integration between our slider actuator and Arduino controlled motors. Currently we do not know whether they will coordinate well, so test will be done next week. We already have a fall back plan, that is another type of off the shelf motor that comes with with linear gear. The motor is relatively slow compared to other solutions, but we know it can be easily used.

Were any changes made to the existing design of the system

Depending on the result of the hardware-software integration, we will decide whether to scale down the project or not next week.

No Schedule update at this time

Ziyu’s Status Report for March 30th, 2024

What did you personally accomplish this week on the project?

After some tweaking with the 3D printer settings, I’m able to reduce the size from 3x to 2x the American braille standard, leading to significant miniaturization. I also designed and 3D printed a scalable base, which is used to hold a single braille cell and its corresponding two sliders now, but can linearly expand to hold more in the future.

Is your progress on schedule or behind? If you are behind, what actions will be taken to catch up to the project schedule?

The progress is on schedule in terms of building a robust slider actuator. The progress is behind schedule in terms of building out a fully specced product. Importantly, because the actuator fabrication process is so intricate, we should communicate internally about reasonably scaling down the project.

What deliverables do you hope to complete in the next week?

I will work with Samay to integrate his motor into my based braille cell. Right now the slider can be moved by hand, but next week to need to fully automate this process, and conduct testing on slider’s move speed, location detection, etc.

Ziyu Li’s Status Report for March 23rd, 2024

This week I focused on iterating on the fabrication method for for braille slider actuator, and have the following results:

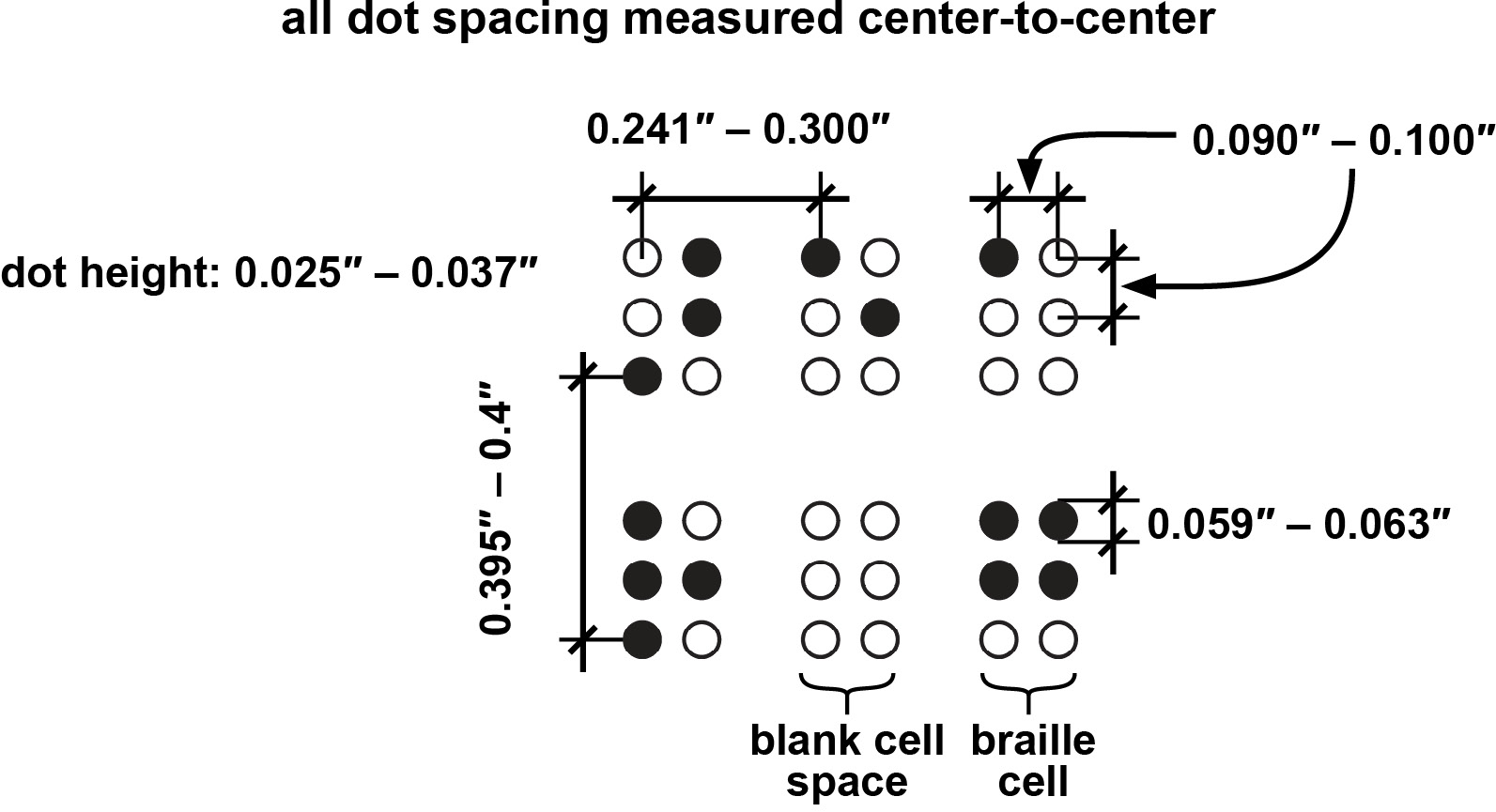

Size:

The ideal size requirement is shown above, which reflects the standards published by braille authority of north America. After several attempts to 3D print my CAD design in this dimension, I found that this miniature scale is nearly impossible to achieve, and the few actuator parts that did got successfully printed are all too fragile to meet our rigidity requirement. This is a problem that cannot be easily solved without major changes in our fabrication method and material, which we deemed outside of scope of this project and our open source requirement.

After much more testing and iteration, I have found that three times the standard sides provides easy fabrication while retaining a reasonably small size. The size of our tested module is still within limits because we have seen much bigger braille texts in use in public settings such as those in museums and elevators.

Deliverable for next week:

Next week, we should start integrating our electronic parts with the fabricated and tested actuator, in preparation of our interim demo. The end result should be a standalone 3×2 braille cell, that can be actuated by the Arduino nano controller automatically according to some set patterns in code.

Ziyu Li’s Status Report for March 9th, 2024

What did you personally accomplish this week on the project?

- I detailed the layout of the device in CAD to get a better sense of how different parts will fit into each other. I also cleaned up the CAD a lot to make it fabrication ready.

- Design report writing.

Is your progress on schedule or behind?

The progress is on schedule as long as we can start 3D printing on Monday.

What deliverables do you hope to complete in the next week?

3D printed design with different size / slope / … (every CAD parameter mentioned in the last report) and a report of how well each is functioning.

Team Status Report for March 9th, 2024

What are the most significant risks that could jeopardize the success of the project?

This remains the same as last week. As we carry out our fabrication test next week, we will have more detailed insights to this question.

Were any changes made to the existing design of the system?

Same as above.

A: Global Factors

The development of an open-source, DIY-able refreshable braille display represents a significant advancement in making reading and digital communication more accessible to visually impaired individuals globally. By prioritizing affordability and ease of construction, this project addresses a crucial gap in the market, where existing devices are often prohibitively expensive, thus limiting access for many around the world. This initiative not only empowers individuals with visual impairments by providing them with the tools to build their own reading devices but also fosters a sense of community and innovation through shared knowledge and resources.

B: Culture Factors

The integration of cultural factors is essential for ensuring its accessibility and usability across diverse communities. Through our open source software, user can easily import customized characters set and text2braille converter, allowing the access to braille education to a diverse community of the visually impaired population. Our project’s braille converter mechanism and translation software also utilizes the unified standard grade 2 braille structure, making sure all the blind communities are benefited. One of the goals of our product is to address the comparatively low literacy level among the blind population. As our project attempts to bridge the gap in literacy level between those who are blind and those who are not by teaching braille through technology, it allows the blind community to have access to language as much as the others. To add on, it is to be noted that culture for the blind, especially those who are innately blind, is under represented due to their lack of access to written verbiage. By providing them a tool to develop their command of written language, it strengthens their cultural interactions and representations to the world.

C: Environmental Factors

The environmental impact of creating a DIY refreshable braille display is significantly mitigated by its open-source and locally producible design. This approach reduces the carbon footprint associated with manufacturing and global distribution of commercial devices, since materials can be sourced locally and devices are built on-demand, minimizing waste. Furthermore, this product will allow for users to input any text file and subsequently be able to read the braille translation, as compared to depending on physical, paper print. This will reduce the dependence on paper for the visually impaired population and further contribute to mitigating environmental waste.

A: Written by Ziyu

B: Written by Yujun

C: Written by Samay