I evaluated the YOLO model’s performance with unit tests as described in the final presentation and team status report (using a dataset of test images), and found that the model’s performance was below what we initial set for our use-case requirements. Examining the images that the model misclassified, I found that it would fail to classify certain objects that weren’t well-represented in the training dataset, like milk jugs. I collected a larger dataset of recyclables to train on, and also added some trash images, and trained new version of the model. This one performed much better, with accuracy scores pretty much in line with the use case requirements.

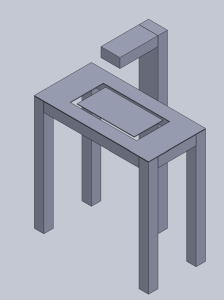

I also made progress with the mechanical build. The shelf that we wanted to use was ordered very late, and might not arrive in time. After discussing with the group, we decided to make the structure ourselves. I figured out the dimensions for the table, CADed a design, and enlisted the help of a friend with woodworking experience to build it. We used scrap wood from Techspark, so the table won’t cost anything in our budget. Some adjustments have to be made, like the camera holder (more details in the team status report), but the build looks good, and I’m glad we were able to put it together on such short notice.

My plan for next week is most finishing up the build. The camera holder will need to be raised, and the door needs to be laser cut to a size that will fit the hole. We will also be wiring everything together.

Schedule looks good, we should be able to get a working project done for the video.

Here is the CAD of the table: