In addition to the display screen attached to the front of the recycling bin, we decided to also incorporate a phone app that users can use to track how much they are recycling, receive recycling tips, and also keep a recycling streak, and earn badges for certain achievements. The reason why we added this change is because while a display screen is useful for users to see how much they are recycling, it can be difficult to show more complicated statistics on an LCD screen. Adding a web app will make the user experience better, and allow us to add more features that encourage users to recycle more. While most of the app can be implemented using free resources such as react, incorporating things like user authentication to connect the app to a specific recycling bin would require the use of AWS services, which we may need to pay for if we exceed the free tier’s limits. Luckily these AWS features are pretty cheap and shouldn’t cost more than a few dollars, and since we have a lot of room left in our budget, it will not impact our costs and budgeting very much.

Adding a major component to our project adds some more complexity to the design, as well as some risk. We will have to work out how to send data from the recycling system to the web app, but we have a lot of options, with the Jetson and Arduino both having wifi capabilities, or we could also add a Raspberry Pi (which has better internet connectivity features) specifically to support the web app. In the worst case scenario, we could also drop the web app and only show statistics on the OLED displays.

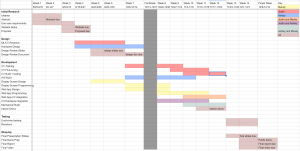

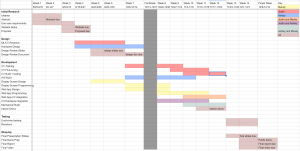

This is our updated gantt chart for our project with the added web app.

The following are answers to questions about how our design will meet the specific needs for global, cultural, and environmental factors.

Part A: Done by Mandy Hu

EcoSort is designed specifically for use within the city of Pittsburgh, as its object classification system of what can and cannot be recycled are based on Pittsburgh’s recycling laws. However, Pittsburgh’s recycling laws are very similar to laws in other parts of the country and the world that also use single-stream recycling. Therefore, although some specifications may be slightly different based on where in the world the user is, using EcoSort still will help improve recycling habits and decrease the amount of wishful recycling. That being said, we recognize that in certain parts of the world, recycling is already much more effective than in America, especially in countries such as South Korea and Germany, which use multi stream recycling. In these countries, EcoSort will not be particularly useful, as they already have well thought implemented recycling habits.

EcoSort is also made to be user friendly no matter where it is being used. The usage of it is similar to any regular trash can or recycling, with only the stipulation that items must be placed one at a time. The actual bins are the same as normal trash and recycling bins, and the mechanics to remove them and empty them are simple and require no knowledge about technology. Although it comes with an app, the bin does not require connection to the app in order to be used, so users who are not tech savvy may choose to forgo the app in order to simplify the process as well.

Part B: Done by Justin Wang

EcoSort’s target audience is Pittsburgh homes, and as a result it was designed using Pittsburgh recycling laws, namely single-stream recycling. However, EcoSort may be used by people with different language and cultural backgrounds, and we want EcoSort to be easy to use for anyone in our target demographic, no matter their background. To that end, the recycling and trash bins will be labeled with symbols that can be understood by anyone. For the bin that holds the recycling, we will choose a bin that has the recycling symbol (three arrows in a triangle), and is a different color. We will also label the bin slots (where the individual bins will go) with symbols. EcoSort will be easy to use, so as long as the bins are in the correct slots, a user will only have to place items in the center of the platform under the camera (this will also be labeled), and the sorting process will happen automatically.

If we go forward with the web app for recycling statistics tracking, then we can also look into supporting multiple languages. I am not the team’s expert of web apps, but doing some research I found that web app frameworks like Django or Flask support l10n, or localization, which can allow a web app to automatically translate its contents without have to change any code. We will look into this further as a part of planning the web app.

Part C: Done by Ashley Ryu

EcoSort aims to contribute to environmental sustainability by reducing recycling contamination, which has significant impacts on natural ecosystems and resource conservation. By automatically sorting items into either recycling or trash bins, users will properly recycle items even when they are unsure if an item is recyclable or not. For safety, when the system cannot classify an item, it will sort it into the trash, as it’s better to mislabel recyclable items as trash than to risk contaminating recycling with non-recyclables. This reduces the amount of non-recyclable waste that ends up contaminating recycling streams, improving the efficiency of recycling facilities. Proper sorting of trash reduces harmful waste in landfills, which helps reduce environmental damage to wildlife and ecosystems. In summary, EcoSort helps people develop better recycling habits by making sure more items are properly recycled and reused. This reduces waste, protects wildlife, and saves natural resources for the future.