What did you personally accomplish this week on the project? Give files or photos that demonstrate your progress. Prove to the reader that you put sufficient effort into the project over the course of the week (12+ hours).

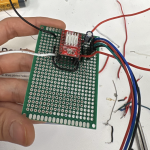

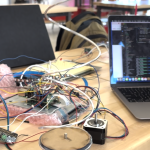

This week, I worked with Anna to finalize our final presentation slides during the first half of the week. We also received our new RPi 4 this week, so we spent some time getting the RPi up and running with all the functionality we’d implemented before our other RPi had burnt up. Once we got that working, we were eventually able to get all the motors working as intended with the protoboards that Anna and I had soldered last week. After verifying that all 6 worked with our GUI code, I was able to attach all the motors to the dispenser coils I’d made earlier and mount them all inside the vending machine. In the midst of burning out the RPi, we’d also found out that our speaker bonnet stopped working (most likely burnt out) last week, so we had to order new speaker components. Once this was delivered, I worked on soldering the connections onto the new bonnet and integrating speaker code with the GUI. At this point, we were able to get everything electrically integrated and mount all of our components into the machine. We had to do some integration tests to debug some of the main dispensing functionalities and make sure that the timing of all the components made sense, like getting rid of some obvious lags between when the snacks would get dispensed and the LEDs + speakers would do their thing. Once this was finalized, I worked debugging and integrating the proximity sensor to make sure that it’s functionality conformed to what we had outlined in our use case requirements. This mainly consisted of tweaking the sensor sensitivity + output hold time, as well as playing around with some logic relating to when the timer would pause and resume, since we needed to factor in the fact that the PIR sensor would generate a response only when it detected motion, rather than continuous presence (what we want). Once this was integrated, we were able to get some end-to-end tests recorded.

Is your progress on schedule or behind? If you are behind, what actions will be taken to catch up to the project schedule?

My progress was behind schedule after our road bump last week with the burnt out RPi, but it was made up for with everything that we were able to accomplish this week as a team.

What deliverables do you hope to complete in the next week?

This upcoming week, my focus will be on getting the final poster finished, as well as prepping for the final demo and reports due this week.