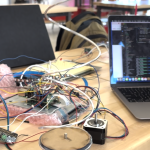

Thankfully, we were able to fix the biggest risks we faced just 1 week ago before the final slides presentation. Early on, a major setback occurred when our RPi and other components were damaged during motor integration. As a result, Ashira and Anna prioritized restoring core functionality, which delayed system integration and testing. To manage this, we plan to meet over the weekend to complete full testing and collect final performance data. Time constraints remain a challenge, but our focus is on thorough testing during this final sprint.

Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

One major design change involved the proximity sensing system. Initially, we planned for the PIR sensor to continuously detect the user’s presence and immediately pause the timer when the user left. However, we discovered the PIR sensor only detects heat motion, not continuous presence. To adapt, Ashira modified the logic: the system now pauses if no heat motion is detected after every few seconds, resuming once motion is sensed again. This workaround required additional coding for both the sensor code as well as the countdown because we realized that if the timer was manually paused and heat was detected, it would resume the timer, which would not be ideal for situations were the user actually needs to pause the timer. The main cost was a slight reduction in precision in terms of the sensor accurately detecting the user, which was mitigated through careful tuning of the motion detection intervals.

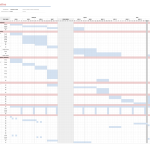

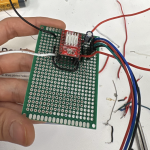

Provide an updated schedule if changes have occurred. This is also the place to put some photos of your progress or to brag about a component you got working

To see it working, refer to this demo video

List all unit tests and overall system test carried out for experimentation of the system. List any findings and design changes made from your analysis of test results and other data obtained from the experimentation.

Unit tests:

- Touchscreen

- Simulated touch events at multiple screen locations to check overall functionality and tested usability of the GUI

- Verified that all GUI elements were responsive and functional under user interaction

- Result: 100% of trials successful; interface is intuitive and robust

- Stepper Motor + Motor Driver Subsystem

- Ensured correct breadboard wiring and motor driver connections

- Constantly adjusted and verified correct voltage levels for both motors and drivers

- Conducted individual tests per motor/motor driver pair to ensure current was drawn and motors rotated as expected

- Tested rotation both through code and with the aluminum coil mounted, oriented sideways for actual vending configuration

- Found that motor drivers were extremely sensitive and prone to burning out

- Breadboards caused instability with more than 3 motors connected along with other peripherals — led to transition to protoboards

- Discovered motor shields exist to simplify setup, but this was found too late in the semester to redesign

- Result: Passed unit test for reliable snack dispensing, but required very careful wiring to avoid malfunction from loose connections or voltage drops

- Ultrasonic Sensor

- Initially tested using print statements to confirm distance measurements and motion detection

- Detected any object within range — led to serious false positives from unintended movement (e.g. nearby hands, chairs, passing users

- Determined that it was not ideal for reliably detecting focused, human presence for our use case (study session verification).=

- Result: Failed unit test for presence detection due to lack of specificity; ultimately not used in final design→ PIR sensors

- PIR Sensor

- Initially tested with print statements to verify detection of human heat

- Found inconsistencies in detection; refined test by using an LED indicator to show real-time presence/motion detection

- Conducted 10+ trials: user walked away from sensor range; checked that timer paused accordingly

- Detection sensitivity varied with distance and environment, but overall logic worked as intended

- Result: Passed (with some variation in accuracy and delay)

- LEDs and Speakers

- Verified that visual and auditory signals triggered after the study session ends

- Ensured response latency between timer hitting zero and signal activation was ≤ 1 second

- Result: Passed

Integration Tests

- Touchscreen Integration Test

- Verified that touch inputs triggered correct system responses (e.g. starting a session, selecting snack)

- GUI reliably linked to backend logic

- Result: ~90%+ accurate response rate under integration.

- System Integration Test

- Verified complete chain: session timer → PIR detection → session completion → motor rotation → LED/audio feedback

- All subsystems successfully interacted

- Result: Passed

- End-to-End Test

- Full test from starting session → simulating user leaving → resuming → countdown to zero → snack dispensed and notifications triggered.Snack dispensation consistently occurred within 5 seconds of session end

- Result: Passed