Over the past week, I smoothened out some of the mechanical aspects of the project. I lengthened the tensioner to apply more tension to the belt to accomodate any potentially higher speeds or loads the team may want to try. The team was also experiencing issues with our belt drift over to one direction. I solved this by placing tape and slightly increasing the diameter of the roller opposite the side the belt was drifting towards. This allows the belt to have more traction on that side and fight the tendancy to drift over in one direction. This will contribute to much greater ease while the group tests towards integration and validation of our overall system. Moving forward, I will freeze any major mechanical changes and simply serve as support to my group mates in their primary tasks.

John’s Status Report for April 19th, 2025

Throughout this week, I finished manufacturing and assembling the the ramp sorter for the team to begin full-system sorting. The ramp was designed with laser-cut scrap MDF found in techspark. It was primarily fastened by gluing it together with additional support pieces for more surface area.

Below is an image of the ramp’s assembly from the laser-cut frame.

Below shows an isometric view of the ramp nearly assembled.

Finally, below shows the angled ramps I placed to allow for more consistent object manipulation, ensuring the object travels down the center of the ramp and in the direction the ramp is facing.

Moving forward, I will continue to serve as mechanical support to the team during testing and into our final demo day.

Additional Question:

I learned about more modern forms of 3D printing. This primarily happened as I went to Roboclub to 3D print many of our components. There were more modern methods of printing supports than I was used to. I also learned more about the process of ML engineering. Although I didn’t directly work on the ML/CV aspects, I did occasionally help in the planning and literature review/researching for our next steps. With him, I learned how to look for these more advanced ML models and datasets to make our applications more effective.

John’s Status Report for April 12th, 2025

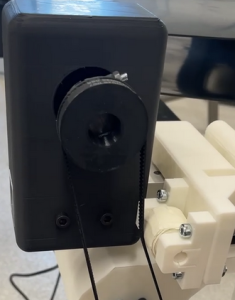

This week, I addressed an earlier issue that arose as we assembled our project which was that the calculation for the timing belt was not correct. I designed and 3D printed a tensioner out of spare PLA to provide more tension to the belt and allow the belt to maintain engagement with the pulleys under higher loads. This was sufficiently addressed and leaves room for more or less tension to be added since it is only layers of masking tape that comprise of the roller’s volume.

I also began gathering materials that will help create the ramp soon. In the coming week, I will need to reprint some modules with the servo components, and use scrap parts in order to create the ramp for our project. However, the goal for me is to get the entire mechanical system ready for integration and testing for the team.

John’s Status Report for March 29th, 2025

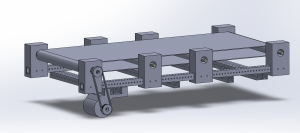

This week, I finished manufacturing the major hardware components we were planning to 3D print, so I was able to begin putting together our more major hardware components. With the assistance of the others, I was able to nearly fully assembly the conveyor belt today. Shown below is the primary structure of the conveyor belt and its roller structures which might stick with us to our final design. Otherwise, our plans remain the same, if not pushed slightly back since we are progressing a little slower than ideal.

John’s Status Report for March 22nd, 2025

This week, I manufactured all of the materials we would need to begin assembling. Attached is an image of all the printed parts we will need to assemble with our metal structural components. I will proceed with assembling all the material quickly so the team can begin testing the overall system.

John’s Status Report for March 15th, 2025

This week, I worked with the rest of the team to handle our shipping issues to ensure we got all of our parts for today. I have begun 3D printing a lot of the components we will need to manufacture our components. Throughout the next week, I will have to begin cutting our aluminum 1×1 and our hex shafts to size, and finish printing out our components. Once that is done, I will move to assembling the conveyor apparatus. During this next week, I have coordinated with the rest of the team for them to test other components, while I an occupied with all my efforts directed towards getting our mechanical prototype. I hope to get the manual assembly (nearly) complete by the next status report.

John’s Status Report for March 8th, 2025

This week, I coordinated with the rest of the team to finish our design report. I had also finalized our materials to be ordered and will be set to arrive by the time the team is back from the break. I had also cut down on our costs by evaluating which materials are available on campus, and designing sufficient substitute components that will be much cheaper to purchase and manufacture. I hope to quickly get prototypes created once the materials arrive and are picked up throughout the next week.

John’s Status Report for February 22nd, 2025

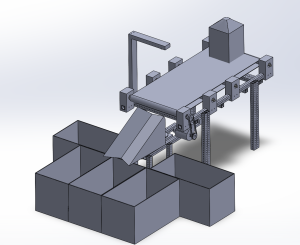

This week, I finished up our final draft for our conveyor design on Solidworks shown below. I also worked with the team to organize our parts ordering, so our orders will be submitted next week during Tuesday. Once the parts arrive, we will need to quickly begin assembling and troubleshooting our mechanical design. Considering parts may take a little longer to arrive than expected, our schedule may have to be pushed back by half a week.

John’s Status Report for February 15th, 2025

At the beginning of the week, we have made a substantial design change which is that instead of individual mechanical sweepers, we will instead simply have a single sorter at the end of our conveyor belt that will guide fallen objects into their designated categories.

This week, we made a lot of progress in the mechanical aspects by detailing the design in Solidworks. This solidifies a lot of our ideas on how we will mechanically design our system and gives us a concrete estimate to a lot of the expected materials we will need. We have also designed a lot of the custom parts that we will need manufacture in our project. For this next week, I will quickly need to finish the remaining design and begin ordering parts for manufacturing and assembling.

John’s Status Report for February 8th, 2025

Personal Accomplishments:

I installed Solidworks and researched typical conveyor belt designs. I have begun drafts of the mechanical designs on Solidworks. I communicated with my group a potential design change to change the form factor of our servo actuators to come in from the side and guide the material into its proper bin instead of directly knocking it. However this may come at the cost of speed.

Schedule:

We are currently on track for the mechanical design as I finish up the draft within this next week.

Deliverables:

As I continue designing, the group and I will eventually figure out which (mechanical sweeper) design will fit our requirements the best. I will also need to finish our first drafts and begin prototyping components. We will also need to finish our list of needed materials which is largely reliant on the designs of our mechanical components.