Potential Risks and Risk Management

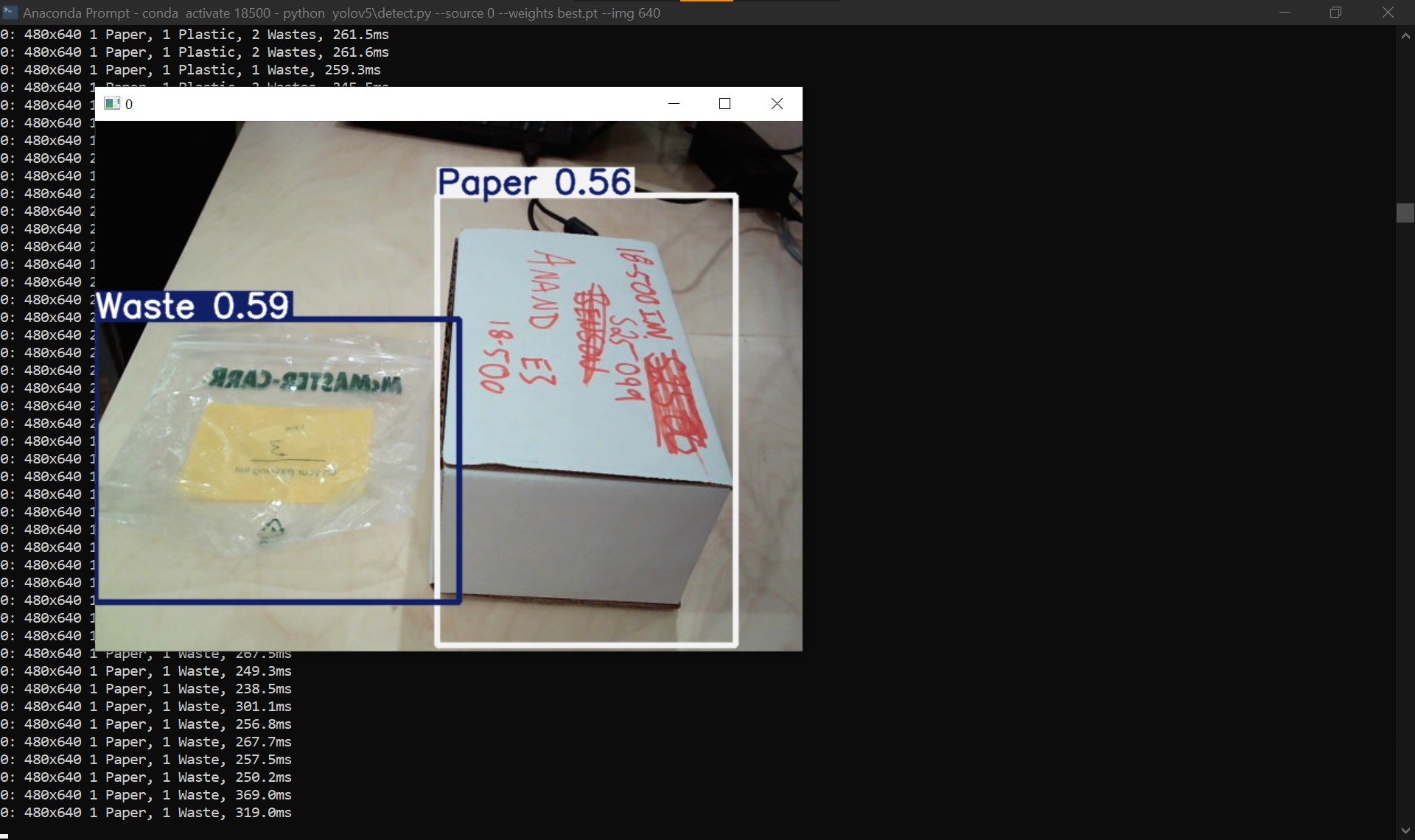

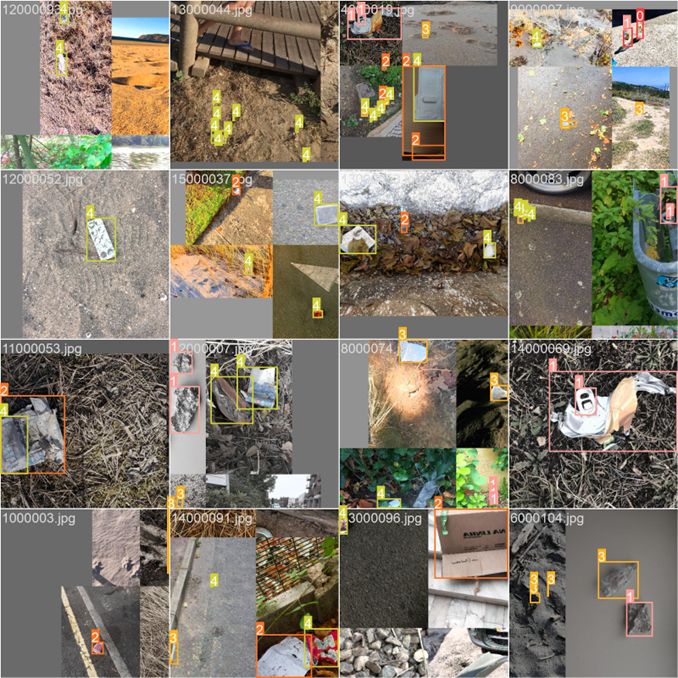

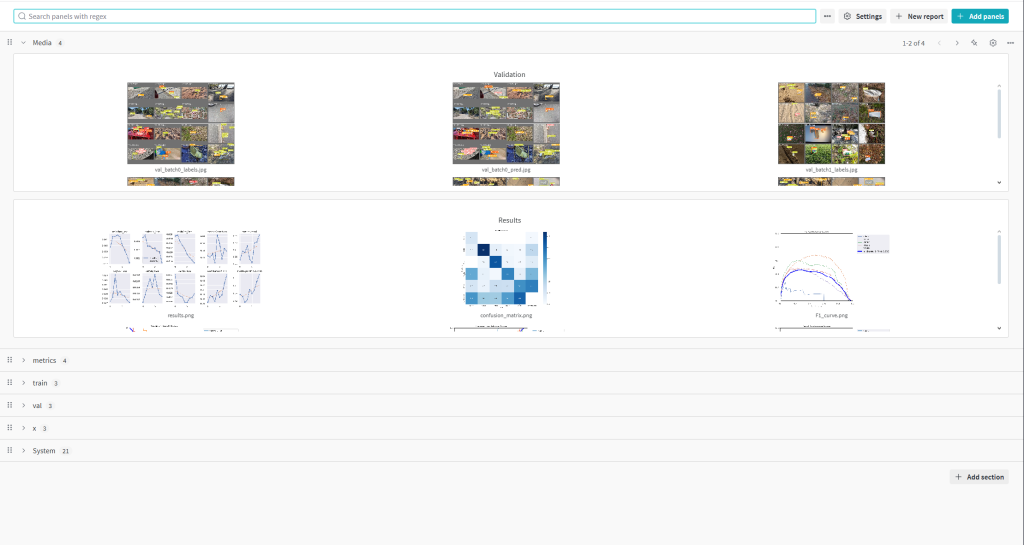

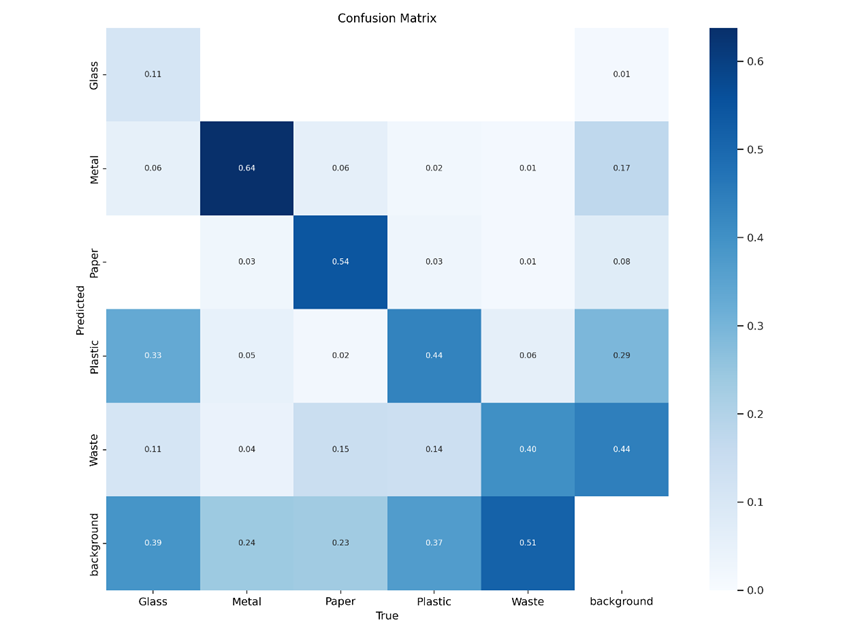

Having started on the build, actuators programming, user interface, and model fine-tuning, we cannot determine any major risks at the moment. While building the conveyor belt part, we realized that the rubber sheet purchased was only good for lining up the rollers once, meaning failure to do so successfully would require purchasing another roll. We have, therefore, been careful when applying the roller for the interim demo. Regardless, we have enough money in our budget to purchase another sheet of rubber should the need arise. While testing the model’s inference in real time, we also noticed that the model performed best at a certain elevation and angle with respect to the object being detected, likely due to how the dataset utilized was oriented. This means that other viewings of the objects on the belt would be detrimental to the accuracy of our detection. We, therefore, are optimizing our camera’s position on the overall product such that it provides optimal inference results.

Overall Design Changes

No major design changes have been made since the last Team Status Report.

Schedule

We are on track with the schedule based on our progress for the interim demo.

Progress Update

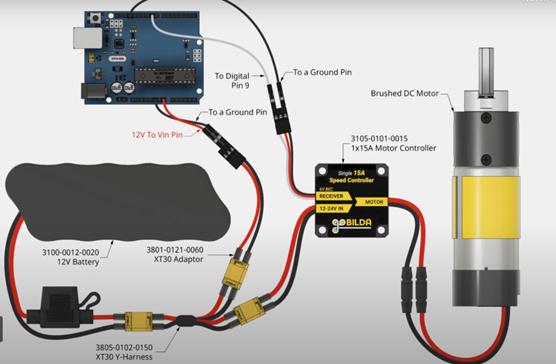

Over the week, we made progress on the mechanical side of things by starting to assemble the conveyor belt. We integrated the motor with the motor driver and were able to test out the setup. We aim to have the belt assembled and ready by the interim demo, and a separate working set up of the sorting and object detection mechanism