Progress This Week:

-

Ollama Instance Deployment:

-

Set up an Ollama instance running the DeepSeek-R1-8B model for Erika to use.

- This model supports reasoning which makes it very good for our usecase

-

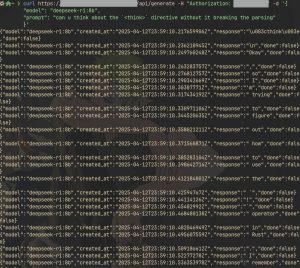

Deployed it behind the existing reverse proxy with token verification for secure access.

-

We can access it both over the cli and using the api

-

-

Python Backend Development:

-

Continued development of the Python backend to add more features and enhance its functionality.

-

Extended API endpoints and improved data handling for integration with Anya’s code and Home Assistant.

-

- Finalized Components

- Finalized and purchased components needed for the final house, planning to install the moment the house is ready on Erika’s end

As the project enters the verification phase, I am planning the following tests to ensure subsystem reliability and accuracy:

-

Electronics Subsystem Verification:

-

Conduct repeated tests on the power monitoring electronics.

-

Measure the accuracy of power draw readings under various loads (fans, motors, lights, etc.).

-

Check the robustness of the sensor communication and responsiveness of the system to rapid changes in load.

-

Use comparison against known reference measurements (multimeter and calibrated loads) to verify sensor accuracy.

-

-

Backend and Infrastructure Verification:

-

Perform functional tests on the backend APIs to ensure correct data logging, error handling, and performance under stress.

-

Test authentication mechanisms, API response times, and data integrity between the Ollama instance, backend, and Home Assistant integration.

-

Simulate prolonged operation to evaluate system stability and resilience.

-