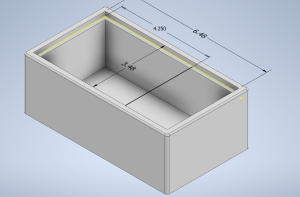

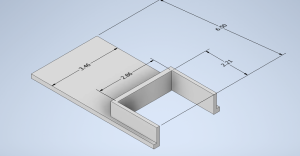

The past two weeks, I have assisted with verifying the circuit for the PCB, made the interface code for the pedal, created test codes for debugging the pedal, met with Chaitanya to debug the interface code, modified the plans for the 3d model due to changes with the PCB, and made designs for the input circuit. The interface code is mostly working, with only the buttons and the rotary encoder still having issues, but this is likely due to some confusion with the Daisy library, as the classes for switches and encoders seemingly are in progress. I have already made some alternate files to test possible solutions and am working on making versions of the code that use the standard GPIO class, which we know works as I used it for the other components, but I am hoping that we can get the Daisy classes working as their debounce function would likely work better for our pedal. For the 3D model, after learning that the PCB size would be much larger than initially planned, I remade the models to fit the new PCB and sliced them, and it seems that the base at this new size would be too expensive to print, so I moved the holes for connections in the base to the faceplate, and will find a premade plastic box that we can use as the base. Overall, this shouldn’t affect the functionality. Our progress seems to be slightly behind, although not by much, as we should be able to catch up early in the week and hopefully start testing. Next week, I will fix the last few things with the interface code, add the holes to the faceplate model and send it for printing, finalize the breadboard version of the circuit for testing, start testing once the audio processing code is fully converted to C++, do my part of the presentation slides, and prepare for the presentation.

As for testing of my own subsystems, as of now, I made most of the circuit in tinkercad while we were designing to test functionality and have made and modified multiple test files for the interface code to debug the individual subsystems of the interface. For the tests I plan to do in addition to the tests we are doing on the whole system as discussed in the team report, I plan to test the system with the full code and compare it to a preset input with just the audio code to determine if there is any significant impact from the interface code on latency, and plan to test the overall noise impact of some of the changes in our design.