General update

- Jetson configured

- Packages installed and configured it to be connected through SSH

- Preparing for design presentation

- Parts ordered for the various subsystems which should begin to come throughout the next week. This will be particularly helpful for the Arduino and gantry system, as we can begin to assemble and test the interface between the two.

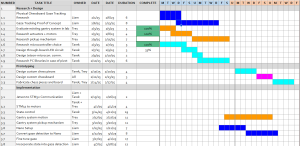

- New Gantt Chart

Potential risks and risk management

- The same risk mentioned last week about the accuracy of the gaze model. If it fails horrendously we will switch to a screen or hopefully find a better model.

- There is a chance that the electromagnet is an ineffective solution. It could be too strong and attract nearby pieces during movement, or it could be too weak that it cannot move a piece through the board. In order to manage this risk, we will test this functionality as early as possible to allow pivots to other pickup mechanisms. The next option would be reverting back to an above-ground gantry that uses a mechanical grabber.

Overall design changes

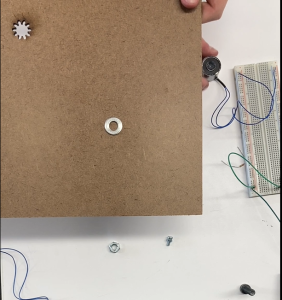

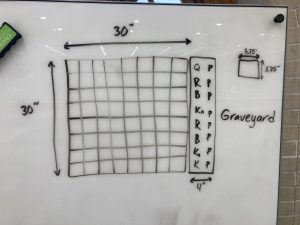

- The gantry system design changed from an above-board system to a below-board. This decision benefits us in several ways, including eliminating the assembly and cost of a z-axis step motor and creating a more clean and accessible board (without the large rails on the sides). The below-board system will still meet all design requirements.

- No other design changes at this time. We expect many of our components to arrive throughout next week, which will allow us to determine if the design/parts are suitable.

Initial Schedule

-

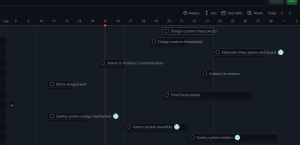

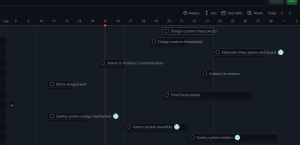

After a conversation with Professor Kim, we have decided to accelerate the schedule of our baseline design. Achieving a minimum viable product (MVP) earlier will allow us to find flaws in our subsystems while still offering enough time for testing and integration. As such, our schedule has changed to reflect the new deadlines that we would like to follow.

Additional Week-specific Items

Part A: Public Health, Safety, and Welfare (written by Trey):

Check, Mate, Vision enhances public health and welfare by making chess accessible to individuals with limited upper body mobility, promoting cognitive well-being and emotional resilience. Studies show that chess improves memory and problem-solving skills, yet its physical requirements can be restrictive. Our system removes these barriers, ensuring all players can access its mental health benefits. Beyond cognitive stimulation, Check, Mate, Vision creates meaningful recreational opportunities, reducing social isolation and fostering engagement. By providing an inclusive and interactive experience, it helps improve mood, alleviate stress, and combat feelings of loneliness.

Our product prioritizes user safety by employing a controlled gantry system that ensures precise and predictable movement of the chess pieces, eliminating any hazards associated with manual handling. The gaze-tracking model further reduces physical strain by accurately tracking eye position at all times. Check, Mate, Vision also enhances overall welfare by fostering independence and inclusion, allowing users to engage in strategic play on their own terms. This promotes self-sufficiency, personal growth, and confidence, extending to daily activities and empowering users to take greater control of their lives.

Part B: Social Factors (written by Tarek)

Check, Mate, Vision is, at its core, a system to enable more people to play chess. This game is enjoyed by millions of people around the world, connecting fans of the game and allowing them to find a new way to socialize with one another and share the human experience. As such, it is important to us that Check, Mate, Vision preserves this aspect of social interaction.

In our ideation stage, we thought about having players play against a machine; however, it was important to us to preserve the human aspects of the game. Playing with another human in front of you, seeing their face, talking to them, and connecting over an appreciation of the game, is a powerful and important element of chess.

We also thought about having users talk to the machine in order to select moves; however, we didn’t want to limit the system’s accessibility to English speakers or those familiar with chess coordinates. Our design ultimately removes as many barriers as possible for as many people as possible to enjoy chess with others, fostering human connection and enabling people to connect with others.

Part C: Economic Factors (written by Liam)

Check, Mate, Vision is focused on providing an affordable chess-playing solution for individuals with limited upper body mobility. Traditional assistive technologies in this field are often bulky and expensive, primarily due to specialized hardware and complex manufacturing processes. By utilizing common components like a camera, computer, and gantry system, we significantly reduce production costs. These readily available parts are less expensive to source and assemble, which lowers the overall price of the system for consumers.

Simplifying the production and distribution aspects also means we can scale up more efficiently, making the technology accessible to a wider market. Reduced manufacturing complexity leads to lower inventory and supply chain costs, which translates into savings for users. This cost-effective approach not only makes the game of chess more accessible to those with physical limitations but also opens up opportunities for educational institutions and rehabilitation centers to adopt the technology without incurring substantial expenses.

This design also includes a piece graveyard, which handles the cases where the user’s piece is taken. The placement of the pieces is optimized to handle potential edge cases such as promotion (where a player can replace a pawn with a queen, rook, knight, or bishop).

This design also includes a piece graveyard, which handles the cases where the user’s piece is taken. The placement of the pieces is optimized to handle potential edge cases such as promotion (where a player can replace a pawn with a queen, rook, knight, or bishop).