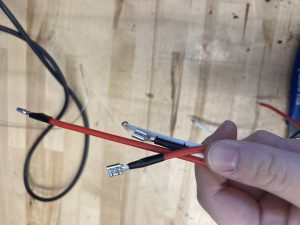

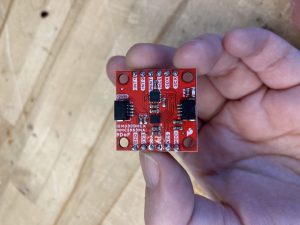

We purchased new parts for the robot (IMUs, wheels, boards, motors, nuts, washers, and M5 threaded rods) and a storage box for organization. We focused on implementation and building and acquired an FPGA to enhance functionality.

One of the most significant risks is the robot’s ability to handle 45º and 60º inclines while maintaining stability. To address this, we are refining our design and testing different configurations. Another major risk is the exposure of electronic components (FPGA, IMUs, etc.) to water during testing. To mitigate this, we are using an extra board on top of the electronics as an extra shield. These were brought up in the project proposal and we decided to address these immediately.

We modified the wheelbase design to better protect the electronics and simplify construction. Rather than a plexiglass shield, we added another wooden board with threaded columns to hold everything together.

Due to our focus on research and planning, our plans were slightly delayed. As a result, we are prioritizing the integration of our current components into the wheelbase to get back on track. Next week, we will assemble the base, begin working with the FPGA, finalize the design proposal before Sunday night, and prepare for its presentation. Moving forward, we will continue refining our design while ensuring that testing and implementation remain on schedule.

As for the extra questions for this week’s status reports, A and B were written by Sara while Raymond wrote C.

PART A:

The slope-stabilizing robot improves public health, safety, and welfare by handling deliveries on sloped surfaces. Automating this process reduces strain on workers and lowers the risk of injuries. The FPGA ensures real-time stability, preventing spills. For hazardous chemicals, the robot minimizes human exposure and reduces long-term health risks. Its stability also prevents agitation, making chemicals safer and easier to handle.

PART B:

Socially, the robot boosts efficiency and safety by simplifying difficult deliveries. Restaurants, cafes, and event spaces can reduce labor-intensive tasks, allowing workers to focus on service. In industries handling chemicals, its stability ensures smooth uphill transport for safer handling, making it valuable for laboratories, manufacturing facilities, and medical environments.

PART C:

For economic considerations, although many robots are supposed to replace humans and help keep business costs down, our robot is meant to aid humans without replacing them. This robot has capabilities specifically for when dangerous chemicals can not be disturbed and shaken. For production, instead of an FPGA, it would make more sense to purchase a microcontroller as the cost of an FPGA does not offset the hardware acceleration that it provides. We are also using wood in our design because it is easy to work with, but for production, it would make more sense to use a material that is waterproof and lightweight such as plastics. This robot is designed to be small and only has a few parts, so distribution should be relatively simple compared to other more complex robotics products.