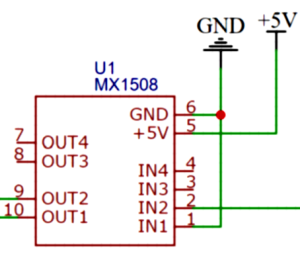

This week we started to shift our focus from one simple drink working to a scaled out system that serves multiple ingredients. With this, managing the more valves and components introduces high chances of leakage, timing mismatches and hardware failures. To mitigate this risk, we created a valve system that been scaled to handle multiple valves with additional screws to minimize leakage. We also tested the integration between the wheel and arm using serial handshakes. A contingency plan will be reverting to fewer valves for the final demo if necessary.

Another risk that we had was timing and synchronization issues. The pouring of multiple ingredients in parallel introduces incorrect timing that can impact the overall latency of the product. To mitigate this, we incorporated multi-threading (concepts that we learned from Carnegie Mellon system classes like 15-440 and 15-418). Specifically, the threading was implemented to handle concurrent valve control with specified delays. Here is the video of that working

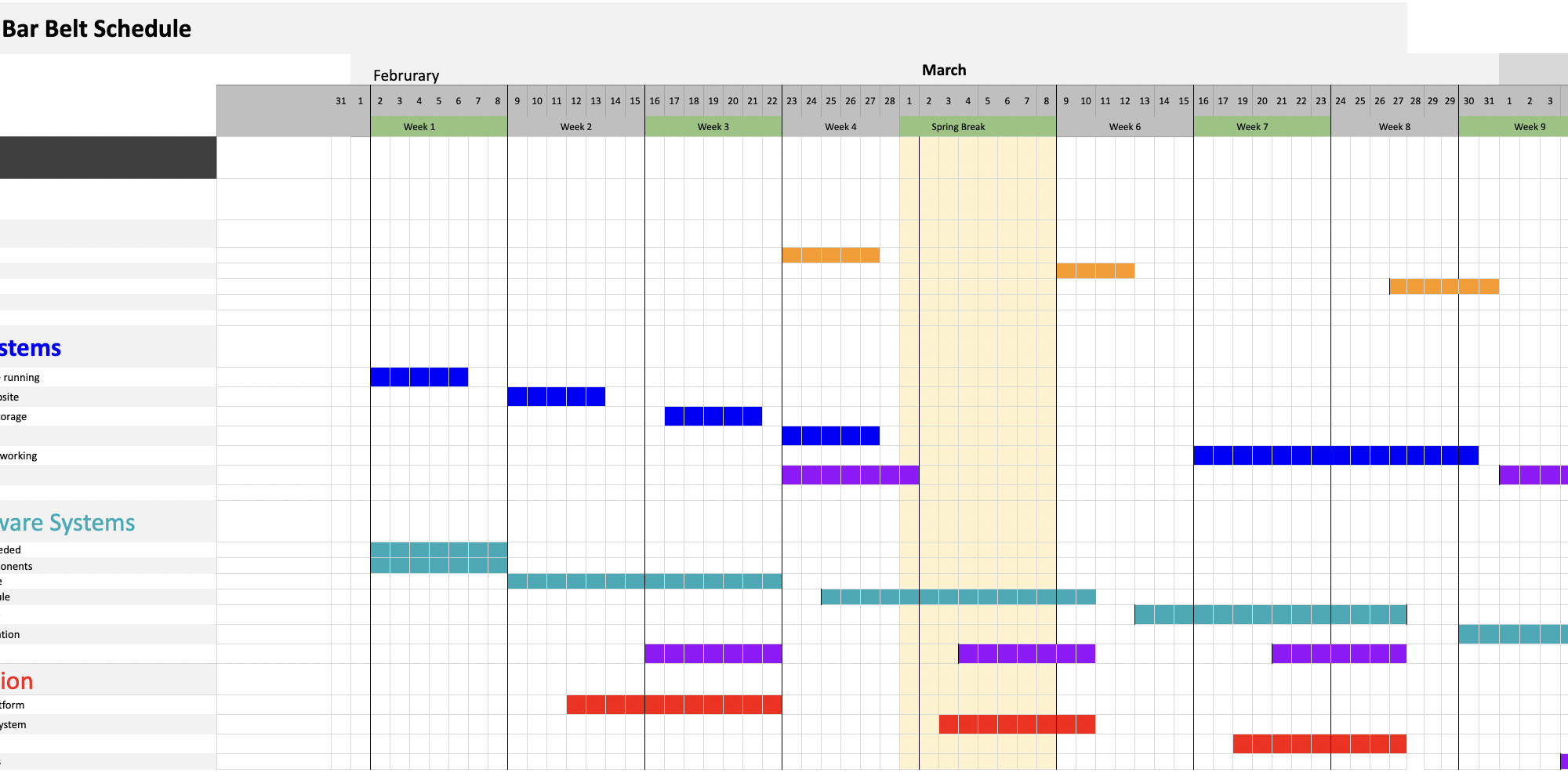

Another risk was the physical support and structural stability. Specifically, we had to create a wooden bookshelf structure was built to mount and support the valves. We will be adding 3D-printed components like the stir cup holder both for functionality and secure fitting.

The dispensing system was redesigned to support parallel valve control and expanded from handling 1 drink to a scalable system for 6 drinks. We did this because we need to support multiple drink combinations on demand.

Some other accomplishments we have is a fully working AI Drink recommender with voice integration. We also had issues with the robot malfunctioning. We were able to get the root cause of the error being a power and motor issue and debugged accordingly.

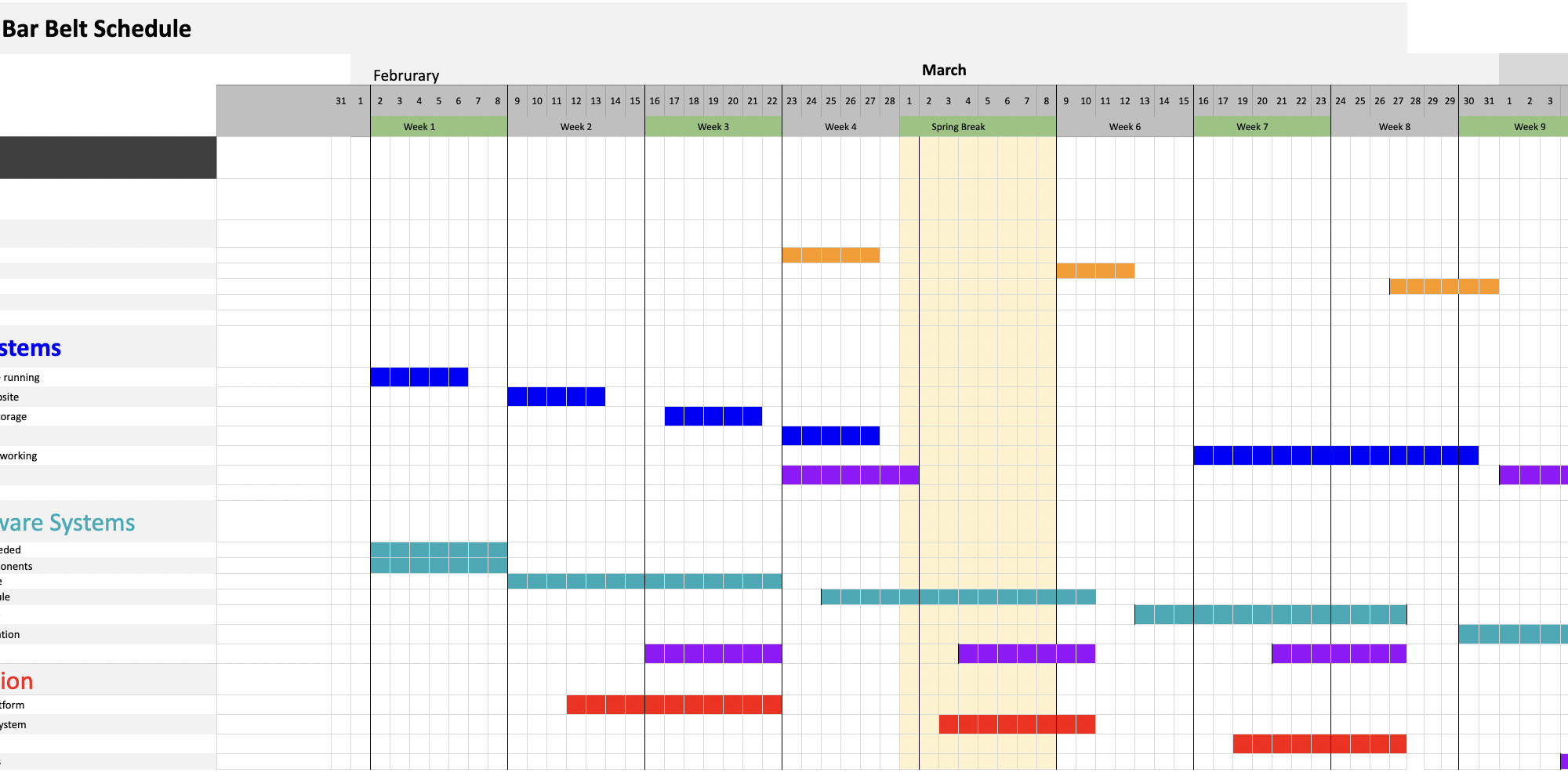

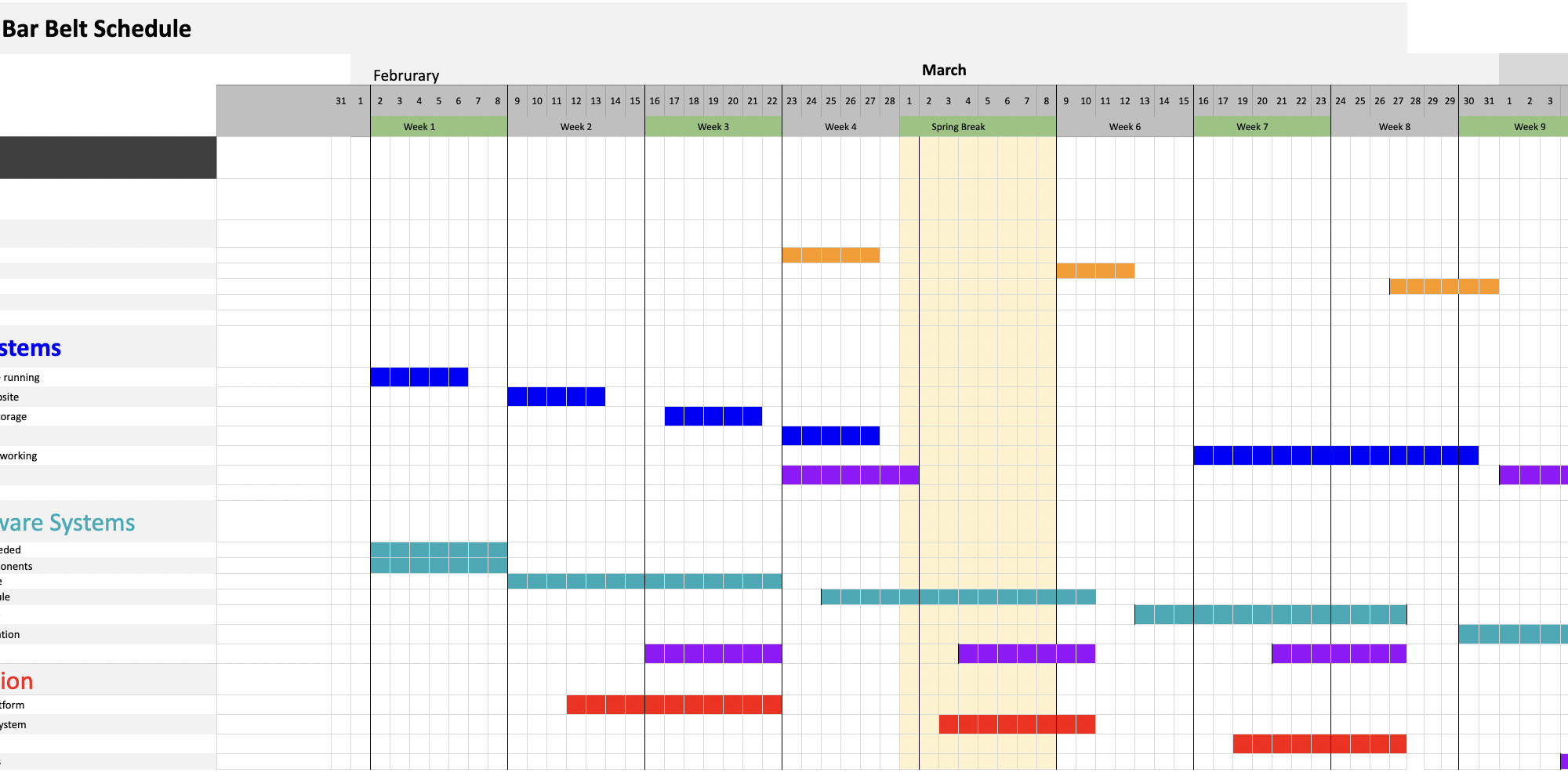

Currently we are still on schedule with the following tasks planned for next week

- scale up to 6 working drinks

- Integrate stirring and cup holder as base.

- Measure and calibrate flow rates for consistent pouring.

- Perform full integration testing

- Finalize hardware layout.

The following are deliverables from this week.

Parallel Valve Control + Integration Demo

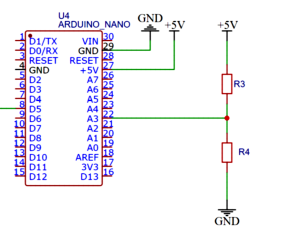

Parallel pouring system now works using Python threading:

Code: Valve Threading Code

Video: Parallel Pouring Demo

Valve System Physical Expansion

Expanded system to handle 2 valves with plans to scale to 6.

Photo: Valve Setup

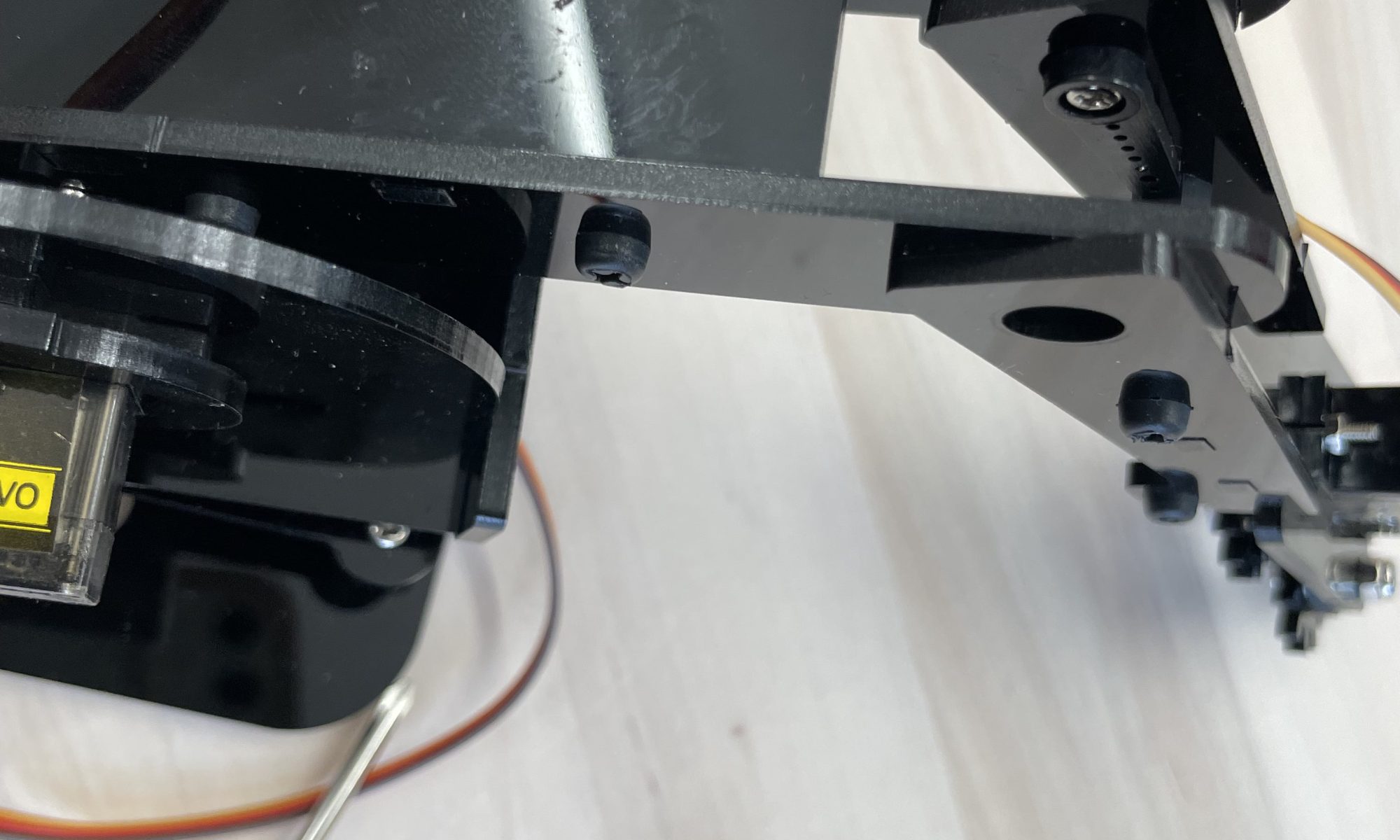

Wheel and Arm Integration

Components now communicate via serial handshakes.

Video: Integration Video

AI Drink Recommender with Voice Interaction

Voice-assisted AI bartender implemented.

Demo: AI Bartender Demo

Core Stirrer Functionality

3D printed magnet holders integrated with motor.

Demo: Stirrer Core Demo