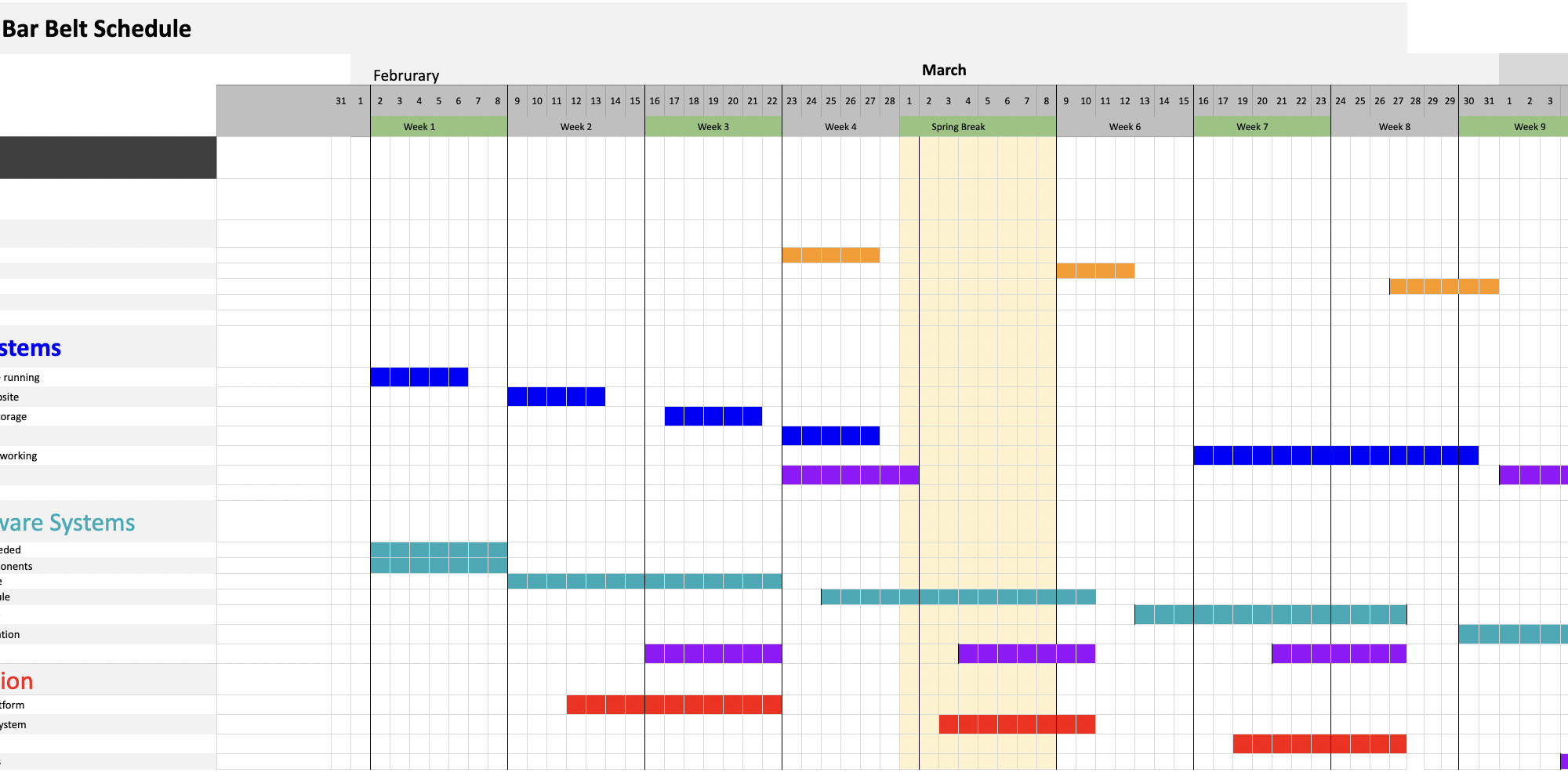

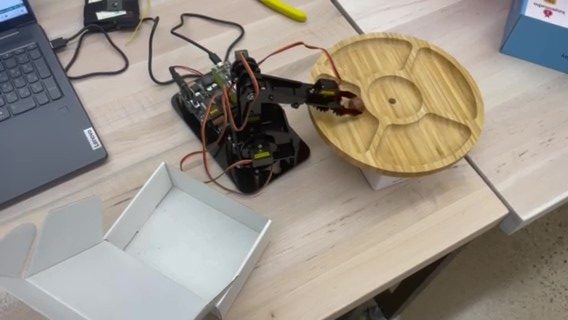

This week, our team focused on finalizing complete system integration and verifying performance through testing. All subsystems were fully integrated and evaluated with tests that include multiple user input scenarios.

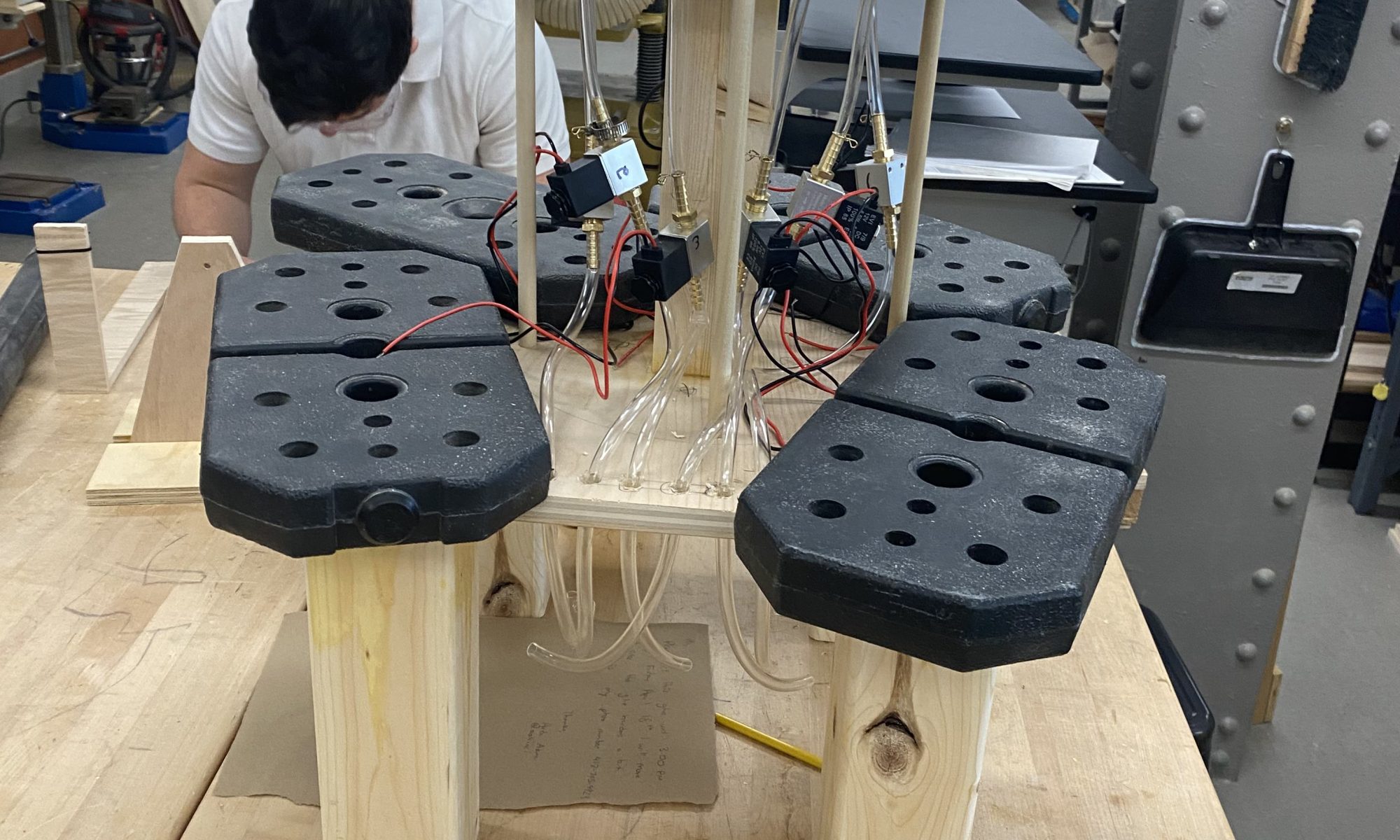

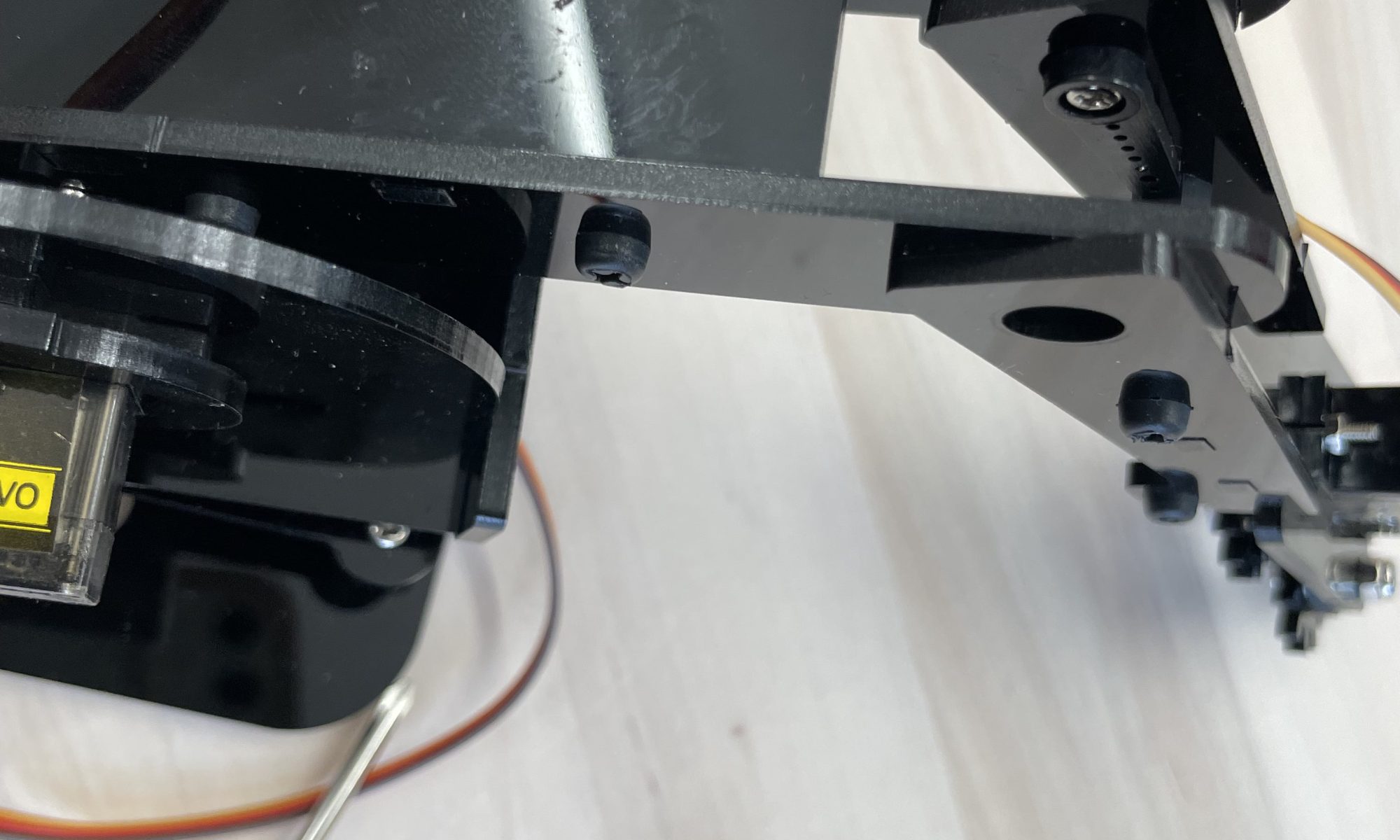

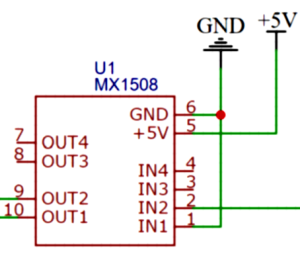

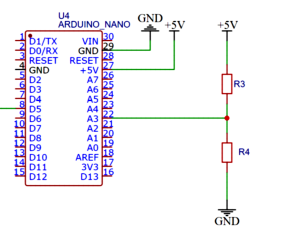

We completed all valve wiring for our six-drink setup and reinforced stability to prepare the system for final presentation and demo. 4 legs were added to the platform for support while freeing up space for hiding and protecting circuitry underneath and improving vertical spacing for fluid flow. We also drilled routing paths for wires and tubing to reduce clutter and providing guided paths for flow. The stirrer was finalized and mounted, providing a fixed, reliable zone for users to place cups.

On the software side, we updated the WebApp styling with custom CSS to improve user experience and performed full testing using the ingredients page, drink product page, and recommendation system with voice input. Across more than 50 test cases, the correct valves fired with 100% accuracy, confirming that our communication protocol and pin mappings are functioning reliably.

Next week, since it’s going to be the final week, we plan to focus on:

- Final system tuning on stability and reliability during live operation.

- Preparing the final presentation and demo.

- Completing the final report, video, and poster.

Risks and Mitigation

- Risk: Overload or wiring disconnects during the presentation due to physical movement or instability.

- Mitigation: Clamps and cable management have been added; the system will be monitored closely during the demo.

- Risk: Timing desync between stirring, dispensing, and garnish placement.

- Mitigation: Predefined command sequences and Arduino checkpoints were implemented to ensure correct handshakes between components.

Design Changes

- There were no major system-level design changes this week. All modifications were focused on finalized physical layout improvements (e.g., base fixing, wiring paths) and UI refinement.

We are currently on schedule.