Team Accomplishments

This week we presented our final presentation to the class including the use case, design decisions, system implementation, and test strategies we used throughout the project. We also ran many tests (up to 20 official tests) to gauge the robustness and accuracy of our system and individual components. We noticed a lot more leakage and spillage than we anticipated during testing, hence we applied a sealage to the valves in order to minimize this risk. Furthermore, we standardized lengths and orientation of pipes in order to get consistent flow rates for easier testing. We also, through trial and error, figured out timings for valves to stay open corresponding to volumes in mL. Furthermore we began working on the poster, completing the pitch, system architecture, system implementation, and testing sections for next week.

Testing

- Ran unit tests involving dispensing to get better accuracy of volume dispensed, the results were within 10 percent error. Also ran tests involving garnish selection so arm has higher success rate of grabbing the various fruits, currently at about 70 percent success. Ran repetitive trials to gauge consistency and any edge cases that could cause system failure, so far the system doesn’t fail but we plan on testing a lot more for confidence in robustness.

- A notable design change was cutting down and standardizing length of wires for more homogeneous flow rates as well as elevating platform to hide and protect circuitry. This ensured the testing of the dispensing unit had standardized conditions and also helped calculate timing for valves to stay open.

- Another design change was adding sealing tape to the valves as we observed a lot more leakage and spillage than we anticipated during testing

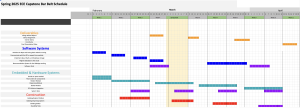

We are currently on schedule