Things done this week

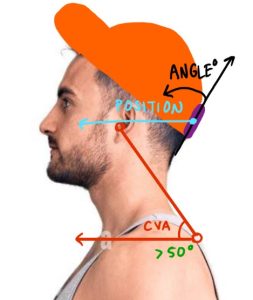

- Processed/analyzed data from the first two testing sessions. While the RMS error for both of these tests is under 5 degrees, I would like to do another round of testing after making a slight tweak to my filter’s coefficients (increasing the process noise of the gyro readings to ideally account for drift), as I noticed the error was increasing slightly in the 30-minute test. This may also be a result of inaccurate manual measurement, but I do want to ensure that the error doesn’t continue to increase as time goes on. Unfortunately, I also must avoid failing my Monday morning 18-447 final so this testing will be happening afterwards at 12pm, before making our poster! Times are tough!

- I’m also speeding up the test data processing by just using screenshots throughout the videos instead of uploading them to Kinovea (this takes a really long time), which has the side effect of a slight lag between the manually measured angle and the displayed IMU estimation. I do not think this is a huge problem as the angles are pretty steady if I am just recording a person working, but definitely something to consider when looking at strangely large errors. I used the video processing for the 10-minute test, and screenshots for the 30-minute one.

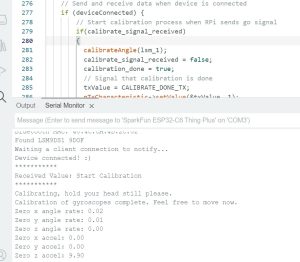

- Finished up tweaks with neck system -> server <-> extension communication, this integration is done 🙂

Progress?

- On schedule, just making the final tweaks and tests. The current filtering is good enough to meet the requirements as of now but I would like to see if I can improve this further. Some of my longer tests (1-hr angle validation, 8-hr battery test) are yet to be completed as I have not had the time to run them on campus, but they are still set to be done before the demo. I’m pretty confident about the battery test, as I’ve had everything running without charging the battery for a while now, but I would still like to officially time it to be sure.

Deliverables for this week, mostly before the demo:

- Set up demo and “real” modes via compiler flags in the Pi start-up script (demo mode = alert for neck angle sent after a shorter time instead of averaging over a minute).

- Finish 8-hr battery test + post-tweak angle tests.

- Poster, video, final demo, final report!

Here’s a link to long-awaited testing results (as of now) if you would like to see them:

Explanation of graphs:

- delta w/curr vs. time: difference between IMU estimation (calculation) and manually measured angle. For the 10-minute test, these values are pretty centered around the average, but seem to be growing (more negative) in the 30-minute test.

- imu estimation + measured w/offset graph: this graph is really just there for fun. It’s just the calculated vs. measured angles.

- delta w/curr vs. measured angle: the goal here was to see if the angle that the IMU was at was correlated with the error (like how before I was having more issues at the +90 degree mark). It doesn’t seem like this is the case though.

- err^s vs. time: graph 1 but the delta is squared so the +/- errors don’t cancel out in the trendline/average.