This week, I tried to finish up working on developing and testing the pressure sensor mat. The first thing I did was connect up the pressure sensors to the RPi/Mux/ADC combination, to see if the readings I was getting made any sense. Once I ensured that this was the case, I was able to focus on testing how they detected lean. Unfortunately, I ran into some issues with the gpiozero library. which took a decent amount of time to resolve. One thing that we figured out is that the bluetooth libraries and the adafruit libraries are not fully compatible, and therefore we might need to have the code for the tw o different components running in two different virtual environments.

o different components running in two different virtual environments.

In the second half of the week, I focused a bit more on testing. i changed out the resistors in the voltage dividers, testing different configurations until I was able to find a resistor which provided a low enough input current to the MUX while also simultaneously giving decent granularity in voltage values.

Another thing I realized when testing is the fact that the voltage outputs of the pressure sensor do fluctuate slightly, even under the same conditions. For this reason, we will require further testing to see if the 0.5 lb granularity can be supported by these sensors.

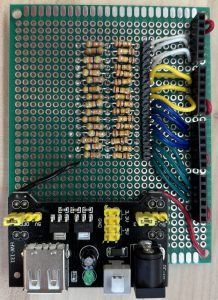

Once I figured out the best combination of resistors (I went with 147 kOhm), I then decided to make a protoboard to hold all of the resistors and wired connections. While the breadboards were good for initial testing, they are too bulky and prone to disconnections to be used in the long run. The main reason we decided to go with a protoboard over a PCB is the common availability of all of the parts that we needed, as well as the timing. I was able to solder the protoboard over the span of Friday/Saturday with components I had on hand, while holding a peer design review and then sending the PCB out for fabrication will take significantly longer.

Finally, this Saturday I worked with the entire team to begin integrating the design. We were able to get the sensors communication with the server, and the extension was also able to send requests to the same server. We also figured out that the latency problem we were having before was a result of a shorted wire between two of the connections, as now the time between input pressure on the sensor and the server response is below 0.5 seconds, a vast improvement to what it was.

I am on schedule. I am finishing up the pressure sensors and am in the midst of integration, with constant design edits and updates as we find improvements to the system.

Over the next week, I hope to continue integrating the sensors. I want to work with Cora to ensure the data that she is receiving is accurate, and use the data I analyzed during testing to write some algorithms in the web app to analyze the sensor input and detect lean. I also want to make a much more stable and sturdy mat for the sensors, as right now it is just a plastic bag with sensors taped on.