Last week (carnival week), I worked with Nancy to synthesize the RTL she had written for the rotary encoder. We debugged and synthesized that code and hooked it up on a breadboard to the GPIO pins of the DE10. After working through a few issues regarding the notches on the rotary encoder skipping to many letters when turning, we were able to successfully synthesize the rotary encoder logic on the DE10. We do, however, have one issue with the rotary encoder not wrapping around from Z to A, which we plan to fix next week — it works fine going from A to Z and backwards through the alphabet from Z to A, however, we have a skipping issue when jumping from Z to A directly.

Last Thursday (carnival Thursday), Nancy and I spent the entire day in 1305 working on the RTL for the MAX Seven-Segment Display. This involved writing a SPI protocol handler to replicate the Arduino code that the MAX7219 chip was designed to handle. However, we were unsuccessful. We tried again Monday of this week, and in a couple hours of debugging we were able to display “DEADBEEF” on the MAX Seven Segment!

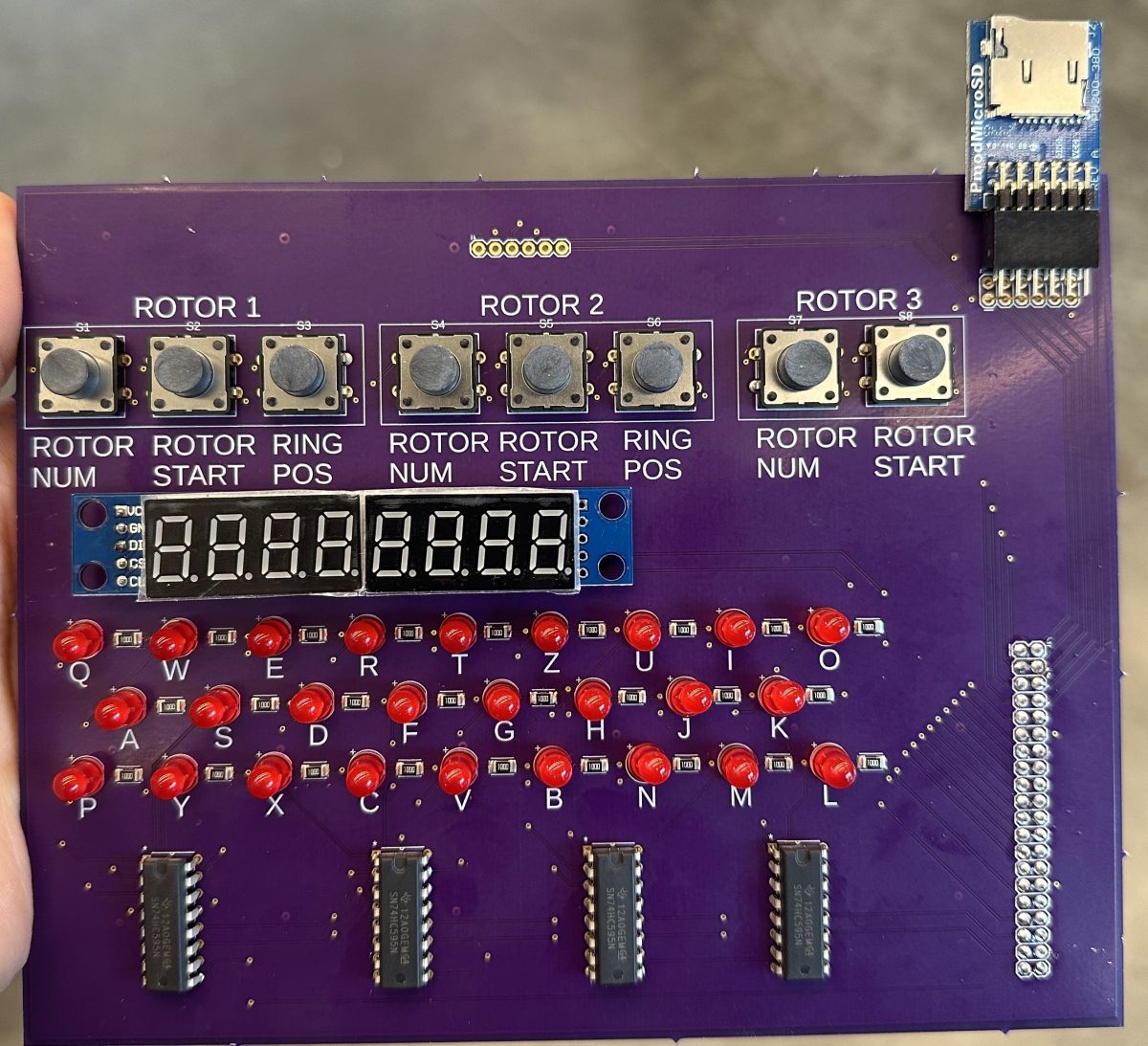

Yesterday (Friday), Nancy and I reconfigured our encryption to take in user input from the FPGA for ring setting and rotor number (previously we only had this capability for rotor starting position which we demonstrated during our interim demo). By Friday night, we were able to configure each setting (rotor number, rotor starting, and ring position) on the FPGA and have these values displayed on the MAX Seven Segment. We tested our encryption for different configurations against the online Enigma simulator and everything worked great.

For verification, we tested the RTL for different ring positions, ring starting positions and rotor number – we verified this against the online Enigma simulator. We plan to user test this with team B4 – Connexus and have them try different configurations and verify with the online simulator that it performs as expected. For the rotary encoder we plan to test its functionality with users trying to use it at varying speeds and intensities to ensure it will hold up in a museum / classroom setting. Nancy and I have already verified for all edge cases (end of alphabet, highest and lowest rotor numbers, etc.) and the encryption worked as expected.

We accomplished our goal this week of writing the SPI handler for the MAX7219 chip and adding configurable for the rest of the encryption settings. Nancy and I only have a few more tasks left on the RTL side — integrating the rotary encoder with the rest of our RTL, writing the RTL for the lampboard shift registers, and finally, the microSD card. We are on track to complete all the RTL and hopefully will be done with everything by the end of next week. This should leave ample time for us to design nice housing for our PCB and finish up all the documentation.