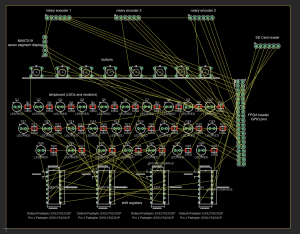

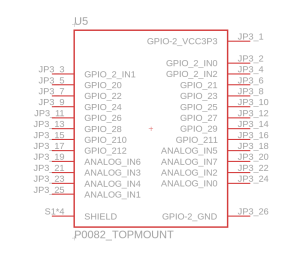

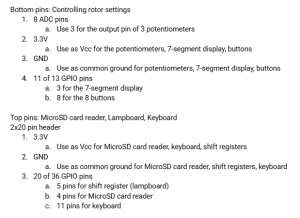

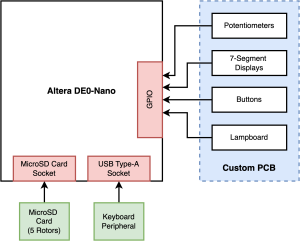

This week we faced larger design changes based on the feedback from our Proposal presentation. This led to an updated design where we decided to adjust the number of modules in order to stick to our primary use case of historical accuracy. Taking the advice and criticisms of our peers and faculty, we incorporated it into our iterative design. This was the determining factor in us deciding to move the functionality from our Arduino to the FPGA. For example, moving the rotor functionality to the FPGA board and by connecting all our external peripherals directly to the FPGA I/O pins. This also included switching our FPGA from the Altera DE10 Standard to the Altera DE0 Nano as the number of pins jumped exponentially from 40 to 80.

Part A: Public Health, Safety, and Welfare Considerations

Our FPGA-based Enigma machine replica is designed to be a safe and historically accurate educational tool for classrooms and museums. By using an FPGA instead of fragile electromechanical components, we eliminate risks associated with mechanical wear, electrical faults, and high-voltage circuits, ensuring safe hands-on use. The modular, lightweight design simplifies transportation and setup, making it easy for educators to integrate into various learning environments without specialized technical expertise. The product will be built with durable, non-conductive materials to prevent electrical hazards, with all components carefully selected to comply with safety regulations.

To ensure quality and reliability, we are sourcing PCBs domestically, maintaining high manufacturing standards and supply chain consistency. The result is a durable and practical tool that enhances historical education while prioritizing safety and ease of use.

Part B: Social Considerations

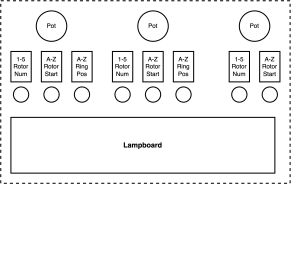

Our project is a historically accurate yet modernized Enigma machine designed to serve as an interactive educational tool. By offering a hands-on learning experience, it fosters an appreciation for cryptography, wartime history, and the evolution of computing. Its open-source design encourages collaboration among educators, students, and enthusiasts from diverse backgrounds.

With a focus on modularity and ease of assembly, the device is practical for use in museums, classrooms, and historical institutions. By making history interactive, we connect historical cryptography with modern cybersecurity discussions, providing value to both history enthusiasts and technology professionals. This project contributes to the broader effort of preserving and communicating historical knowledge in an engaging and meaningful way.

Part C: Economic Considerations

Our project is designed to be cost-effective and sustainable. By remaining open-source, we eliminate licensing and proprietary hardware costs, making it more feasible for institutions with limited budgets. Using an FPGA preserves the logic of the original Enigma machine while reducing maintenance needs compared to mechanical alternatives. The modular design further extends the product’s lifespan by allowing individual components to be replaced as needed.

Sourcing PCBs domestically ensures consistent quality, minimizes supply chain risks, and supports U.S. manufacturing. These choices balance historical accuracy with economic feasibility, ensuring that our Enigma machine replica remains a practical and valuable tool for education and historical preservation.

Part A was written by Nancy, B was written by Amelia and C was written by Tanisha.