This past two weeks I worked on preparing for our interim demo, working on PCB manufacturing tasks and other odd items.

I ordered our stencil from OshStencil. I ran into a few issues with trying to resize our stencil as it was charging us for a lot of negative space even though I didn’t need those extra sq inches. However, I was able to order it and it arrived successfully.

Since our stencil hadn’t arrived for the earlier part of this week, I worked on writing encodings to our Micro SD cards and making sure everything was formatted correctly, and running storage tests. I pivoted from using H2testw to f3 testing so I would be able to check storage sizes as well as corrupt disks.

I also started working on our Final report – specifically the PCB section as that is solely my responsibility as well as updating the Ethics session of our paper based on our Ethics lecture notes and previous status reports.

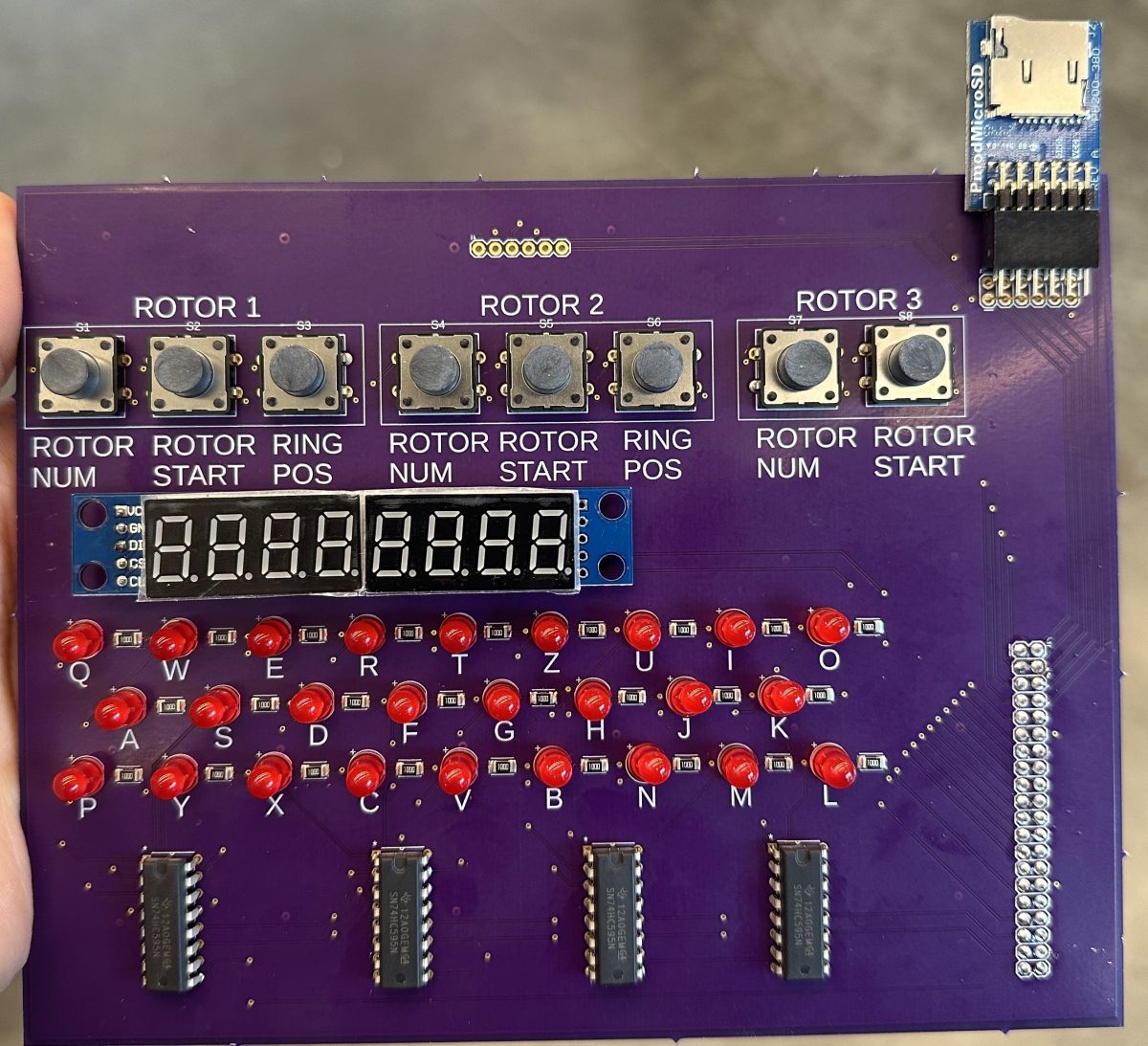

On Friday the PCB arrived (yay!). I immediately fabricated the resistors in the Fab Lab in Techspark and on Saturday I hand soldered the LEDs, 7 segment display, shift registers, FPGA header and the SD card reader and its right angled header. This comprises the majority of our PTH components.

I ran into slight issues as I had planned to desolder the right angled headers that came with the rotary encoder for a clean look and to balance the center of gravity for our users. However, that was proving tricky and I didn’t want to mess with the rest of the board as we got the last 2 rotary encoders in stock and hence have no spares. Due to this, I tried to source right angled female headers on campus but ended up just ordering some. Once these arrive, I can solder the rotary encoder and with that the PCB fabrication would be complete. I have attached a picture of the current state of the PCB to this status report.

This week I plan to run more continuity tests (I did small modular testing as I soldered the PTH components), ensuring all parts are soldered on with sufficient connection and no shorts. For verification I will double check multimeter output against the design schematic and ensure all works as expected (grounds, vcc, shorts etc).

I also plan to work with our Verilog team to on integrating our PCB and FPGA successfully. This should leave plenty of time to have everything working successfully by the end of the semester.