What did you personally accomplish this week on the project? Give files or photos that demonstrate your progress. Prove to the reader that you put sufficient effort into the project over the course of the week (12+ hours).

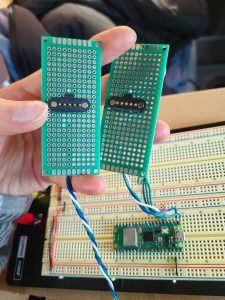

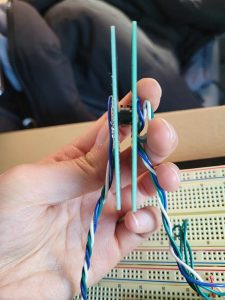

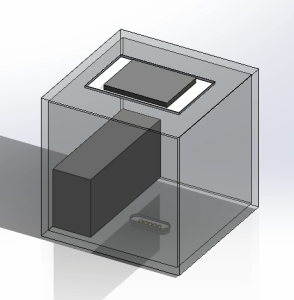

This week I worked on laser cutting the grid, making 3D printed holders for the pogo pins on the grid, assembling, integration of our final product, verification testing and user testing. For the grid I was able to cut all the pieces out and wood glue it together, letting it set for 24 hours before we started playing around with it. Before that I had used scrap cardboard to ensure that everything would fit together and that it was an appropriate height. I found that I didn’t add enough tolerance and therefore had to modify some dimensions. I also initially had engravings to make way for the wires but it did not cut deep enough and took too long to do the engravings so we ended up laying out the wires in the back nicely and taping it down. I also printed out the holders for the pogo pins which helped to align it to its position on the grid ensuring that each pin was straight and flush to the board. These proved to be super helpful when installing the pogo pins and minimized variability in its positioning. I also added standoffs as I realized there would be some wiring on the back side that I didn’t want to get squished when laying flat on the table. I then worked on integrating with the soldered perf board and solidifying all our connections: removing jumpers when possible, soldering the joints and heat shrinking it to provide insulation. There was quite a lot of debugging and retesting connections as it got jumbled while migrating the test board to the grid, however we were successfully able to finish and start testing. I also discovered that there may be manufacturing defects with some of our pogo pins as there are times when the male pogo pins don’t come to the same height and one is sunked down (look here for reference) which may also attribute to some loose connections and why we may have troubles receiving ACKs sometimes. As for verification and testing I worked on uploading 16 different words to each block and at different positions. The way I did this was first starting out with block 1 on position 0, block 2 on position 1 and so on. I then wrote some code to recording the start and end of uploading a word associated with a particular position. I noted all the times and shifted all the blocks down by one so that now I had block 16 on position 0, block 1 on position 1 and so on. I continued this for 16 times and was able to see satisfying results with around 200 ms on average to upload varying lengths of words. I also conducted user tests where we set up the user to play NYT Connections and then Connexus and take a survey. I recruited about 5 people for user testing. I also made sure to weigh and check the size of the block which we found that the weight was 181g and so far everything is meeting our original design requirements. I also am working on graphs for displaying testing metrics for the final presentation.

Look here for more photos and videos!

Is your progress on schedule or behind? If you are behind, what actions will be taken to catch up to the project schedule?

My progress is now on schedule as I have finished the grid and integrating everything. The only thing that is left is more user testing.

What deliverables do you hope to complete in the next week?

More user testing and possibly making minor cosmetic changes. I will also be starting on the poster and looking at comments for the final report.

As you’ve designed, implemented and debugged your project, what new tools or new knowledge did you find it necessary to learn to be able to accomplish these tasks? What learning strategies did you use to acquire this new knowledge?

The new knowledge I have acquired is all the mechanical knowledge such as using the Epilog laser cutters and using Solid works to get the correct dxf files. I also learned that a lot of my designs were a bit of trial and error, I tried to use scrap material where I could to practice and then moved onto our actual product, but you can see that hear and there some of the mess-ups I had along the way, but once I got the hang of it everything became really easy. I also learned more about micropython and creating a protocol for the picos to communicate with the RPi. I enjoyed making a class abstraction to better structure my code so that it was easy for integration. I also became a lot more comfortable at soldering as repeating the same actions while scaling became a routine for me. I also learned how challenging it can be to scale as now there are so many moving parts and variability in places you didn’t know existed, but I think that my team and I came up with a good plan and we have been executing it well to ensure organization such as labeling the blocks and modularizing testing to ensure connectivity and functionality.