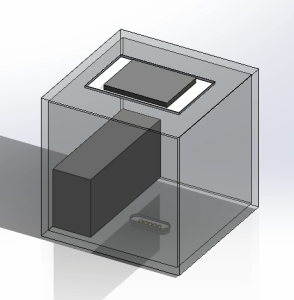

This week I worked on the Design Review Slides, making tables to compare the different communication protocols and microcontrollers that we looked at which ultimately helped us decide on what we wanted to move forward with. I also help to quantify our tests and draw connections to our requirements so that we can better measure our success. I also updated some of the diagrams in the solution approach and the power block diagram to reflect the components that we are going to be prototyping with. As for the Rpi, I helped Wen Hui boot up the OS and set up Real VNC viewer. Also, I made CAD models of our proposed block and planned where we will need to make cut outs for the ports and switch of the battery. I also helped order parts this week and acquire some scrap materials to help us make an initial prototype for next week. Also, I went to Techspark to solder jumper cables onto our battery holders, buttons, and header pins on row LCD to make prototyping easier.

My progress is slightly behind schedule according to our initial gantt chart because we need all the parts to come in before we decide if we actually need a PCB or not. For now I am just modeling where things will go and am planning out what the inside of the block will look like so that maybe we can just 3D print holders for all our components if a PCB is not necessary. I am shifting my focus into preparing as much parts as I can so that we could easily merge things together for prototyping a block.

My deliverables for next week is to create a mock on the block in its entirety with a plan for where each component will lie in the block. I also will work on establishing the UART protocol between the Rpi and Rpi pico as well as get the 2 row LCDs working so that we can display the proper category and flash it with a particular color. After getting all the parts I’ll also decide if a PCB is needed or not. If it is needed I will research the etching machines that are down in techspark for faster PCB development.