A was written by Martin Lee, B was written by Andrew Kim and C was written by Justin Kim.

Part A: … with consideration of global factors. Global factors are world-wide contexts and factors, rather than only local ones. They do not necessarily represent geographic concerns. Global factors do not need to concern every single person in the entire world. Rather, these factors affect people outside of Pittsburgh, or those who are not in an academic environment, or those who are not technologically savvy, etc.

The Automated CardEaler (ACE) is designed with global considerations to meet the diverse needs of casual poker players around the world. By automating the dealer functionality, ACE addresses the common inconvenience faced by casual card game players worldwide– namely, the social exclusion of the person acting as the dealer.

To ensure ACE effectively serves global Texas Hold’em players, the design enforces to follow the typical Texas Hold’em rule. Furthermore, in the future, we’re intending to incorporate flexible and adaptable elements like multilingual audio output and customizable game rules. Supporting multiple languages in ACE ensures accessibility across various linguistic contexts, directly acknowledging global diversity. In total, our product solution not only meets the specific need for unbiased, automated dealing but also reinforces global inclusivity and broadens the product’s appeal in a diverse, interconnected world.

Part B: … with consideration of cultural factors. Cultural factors are encompass the set of beliefs, moral values, traditions, language, and laws (or rules of behavior) held in common by a nation, a community, or other defined group of people.

Automated CardEaler is specifically designed to enhance the inclusivity and engagement of casual card games across diverse cultural settings. Having one player act as the dealer can exclude them from fully participating in the game, potentially conflicting with cultural values that emphasize fairness and equal participation. By automating the dealing process, this machine ensures that no player is disadvantaged by the responsibility of dealing cards, aligning with cultural norms that value equity and full involvement in communal activities. This feature not only democratizes gameplay but also respects the social dynamics of gaming traditions in various cultures, making the game more accessible and enjoyable for everyone involved.

We can also add modifications to the system to enhance the social and cultural aspects of gaming by accommodating diverse player needs and respecting cultural norms around gaming. For example, the system’s language settings can be customized to support multiple languages, making the game accessible to players from different linguistic backgrounds. Furthermore, the machine’s user interface and game rules can be adjusted to align with local traditions and legal standards, ensuring that it respects the cultural values and legal requirements of various regions. This flexibility not only broadens the appeal of the game but also reinforces the cultural respect and inclusivity essential in today’s globalized society.

Part C: … with consideration of environmental factors. Environmental factors are concerned with the environment as it relates to living organisms and natural resources.

Our project doesn’t have a direct correlation with the environmental factors since poker happens indoor and our machine doesn’t require substantial amount of energy or resources to build one. However, if we were to scale this project into actually selling our product and mass production of it might, of course, cost huge amounts of money and energy. Not to address the problem with the environmental factors, but we designed our project in a way that the machine costs as few as possible. This means, the machine is not expected to harm any living organisms or harvest natural resources to a concerning level.

- What are the most significant risks that could jeopardize the success of the project? How are these risks being managed? What contingency plans are ready?

There are currently three possible risks in our project.

Number one: The card recognition system may not work with 100% accuracy. There isn’t much risk mitigation we can add to mitigate the effect of this, so it would be our job to polish it as much as we can.

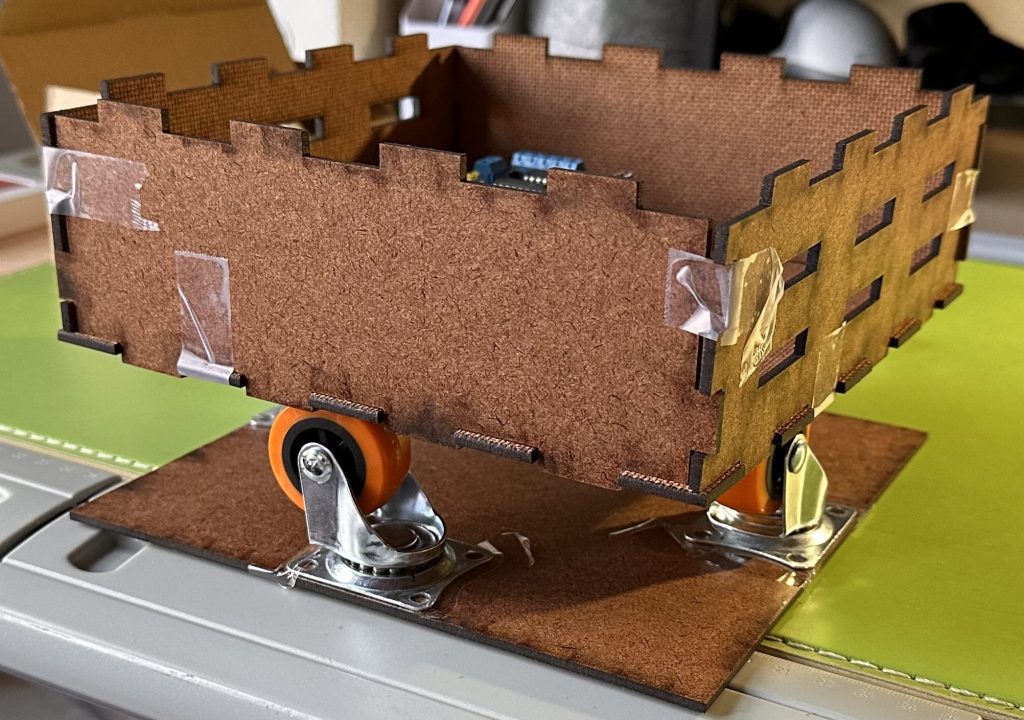

Number two: We may need to buy another motor shield/motor driver because the current one does not support external power supply for the servos. We really want to work with the motor shield we have right now, but in the case that the central servo does not work properly with the machine body placed, we will need to buy a new one that supports external power supply for the servo. Thus, we will need to hurry building the machine body so that we can test if the servo works properly.

Number three: The 3D printed dispenser may not work properly. Thus, we cannot test at all until we print it. We put a lot of time and effort into making sure it will work in the first try, but in the case it doesn’t, we will need to hurry and make modifications.

- Were any changes made to the existing design of the system (requirements, block diagram, system spec, etc)? Why was this change necessary, what costs does the change incur, and how will these costs be mitigated going forward?

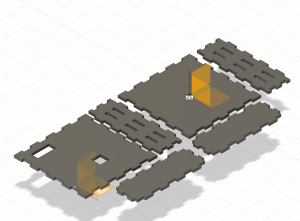

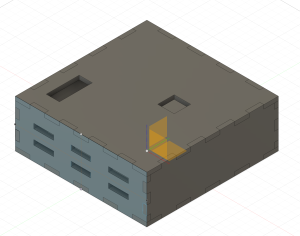

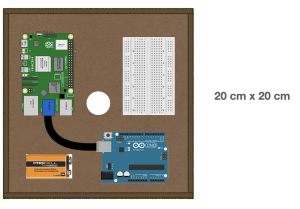

Where we place the parts in the machine body (arduino, raspberry pi, battery, breadboard) may need to change slightly for better proximity between parts that are being connected. However, it is not very different from the 3D model we have in the design report.

Provide an updated schedule if changes have occurred.