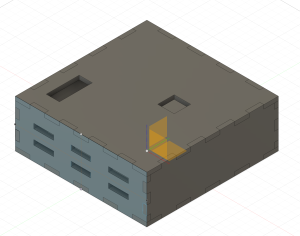

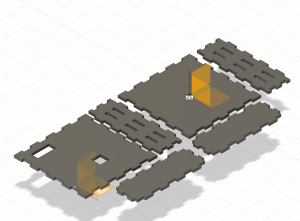

This week, I worked on learning how to make dxf files for laser cutter and making it. It honestly took me a lot longer time to do this, as I had to get the dimensions right.

It also took some time because I wanted to make it in a way that lets me change the hinge size according to the thickness of the mdf I am going to use. This was to add flexibility in our machine body’s design in case we need the material to be less thick to reduce weight or thicker to made it stronger.

Although I did very selectively place the holes considering the size of inner components and their placement, how it actually looks when assembled in real life may be different. So the top part may need to change slightly, but the rest should be fine with what we have right now.

I am behind schedule right now, as I should have already cut this board out this week. So, I will need to do that right away on Monday and assemble them. Good news is that all parts (except for RPI sd card) has arrived, which means I should be able to construct the full machine body now.

I do see it taking some trials and errors, but I hope it won’t take too long. That is why we took some time to plan ahead after all: to reduce number of trial and error.