Now, we have a complete picture of how the machine will look like. We closely examined the required parts and their specifications more closely to make sure they all meet the design requirements we have set for this project. Admittedly, we did run into some problems due to parts we have bought/borrowed that actually did not entirely meet our requirement. However, we have accommodated those and are ready to build the machine starting this week. That is, unless the extra parts we bought arrive late. However, since there was one week gap for the parts to arrive, it would be unlikely.

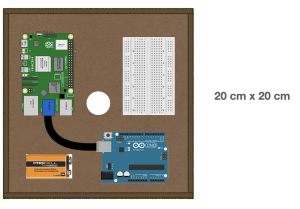

As specified in the design report, the final size of the machine body will be a 20 x 20 x 6 cm wooden box, made by combining mdf plates. The size was chosen after creating virtual images of the assembly as shown above, getting a general sense of the amount of space that would be required for all the parts to fit inside. Although we do not have the dxf file for the wooden plates yet, I am planning on quickly creating those this Monday and hopefully cut them by Tuesday.

Then I will assemble those in to a box and add the caster wheels so that I can adjust the placement of the servo for central rotation. Then, I will add weight in side the box to simulate other parts other than the uno to see if we need to buy a different motor shield to support external power supply or the servo. The one we have currently does not, so it will be drawing power from the Arduino, which is generally not a good idea. However, considering that the load is not too heavy, we thought that the servo may end up not drawing too much current.

In short, it was mostly final polishing of the design plan before moving onto the actual assembly.

We are on track in terms of schedule, and if the servo and the 3D printed dispenser case does not cause any trouble, we will very ahead of schedule by the end of this week (though that would be highly unlikely).